Monthly Archives: November 2015

Super-cool rebar couplers from Ancon

Story

In line with its global reputation for developing reliable, high performance fixing systems for demanding construction environments, Ancon’s latest launch is a range of reinforcing bar couplers designed to operate at cryogenic temperatures.

In line with its global reputation for developing reliable, high performance fixing systems for demanding construction environments, Ancon’s latest launch is a range of reinforcing bar couplers designed to operate at cryogenic temperatures.

Typical applications include the construction of steel-lined concrete storage tanks for refrigerated liquefied gas (LNG/LPG).

Independently tested with cryogenic-grade rebar at a cool -165oC to the requirements of EN 14620-3, the new Ancon CTT range of couplers is available to suit bars from 12mm to 32mm diameter.

Featuring a tapered-thread to simplify bar alignment and engagement, and reduce the chances of cross threading, CTT Couplers are compact in design, so are ideal for use where space is tight, and can be installed quickly and easily, minimising construction time and costs.

The range comprises standard couplers to join bars of the same diameter, transitional couplers for bars of different diameters and positional couplers where neither bar can be rotated.

Export Manager, Hervé Poveda says,

“Although new to the Ancon range, we have already supplied 16,000 CTT Couplers to a LNG storage project in Northern Russia. This is one of the toughest environments on earth. The tanks store gas at cryogenic temperatures on the inside and are surrounded by ice on the outside. Conditions don’t get much tougher than that. The construction team wanted a high performance product with fast, trouble-free installation and Ancon’s solution proved ideal.”

This product launch comes just weeks after Ancon received its second Queen’s Award for Enterprise. The company now holds Queen’s Award for Innovation and for International Trade; these recognise Ancon’s unique ability to develop new and exciting products and make them available immediately through its proven worldwide distribution channels.

A new technical brochure on the CTT coupler range is available to download at www.ancon.co.uk/cryo.

View Ancon's profile:

LG SUPPLIES AIR CONDITIONING AND HEATING TO ICONIC MEMORIAL BUILDING

Story

The National Memorial to the Few at Capel-le-Ferne, on the famous white cliffs between Dover and Folkestone in Kent has been redesigned and updated with a stunning new building, shaped like an iconic Spitfire aircraft with its sweeping wings. The site is appropriately based in the area nicknamed ‘Hell-fire Corner’ due to the intensity of the dog-fights that took place during World War 2, in this part of Kent.

The National Memorial to the Few at Capel-le-Ferne, on the famous white cliffs between Dover and Folkestone in Kent has been redesigned and updated with a stunning new building, shaped like an iconic Spitfire aircraft with its sweeping wings. The site is appropriately based in the area nicknamed ‘Hell-fire Corner’ due to the intensity of the dog-fights that took place during World War 2, in this part of Kent.

Maintained by the Battle of Britain Memorial Trust, the site at Capel-le-Ferne is dedicated to Churchill’s famous “Few” who fought in the skies overhead to keep this country free from invasion. The Memorial itself inspires quiet reflection on the bravery and sacrifice shown by the aircrew – fewer than 3,000 men – who flew, fought and sometimes died in probably the most crucial battle fought by this country in the whole of the 20th century.

The Christopher Foxley-Norris Memorial Wall lists the names of all those who took part in the Battle of Britain, while a replica Spitfire and Hurricane stand nearby as a reminder of the iconic machines they flew to victory. At the edge of the car park, greeting visitors to the site is a low wall bearing Churchill’s famous quotation: “Never in the field of human conflict was so much owed, by so many, to so few”.

The original plan for the memorial was on a bigger scale than the visitor will see today. Many would argue that the final design, by Harry Gray of the Carving Workshop, Cambridge, is moving through its simplicity. It features a striking sculpture of a seated airman looking out to sea, surrounded by the badges of the Allied squadrons and other units that took part in the Battle of Britain.

Independent LG distributor LGCC has had the privilege of supplying the air conditioning and heating services for the new state of the art centre, bringing together the latest Variable Refrigerant Flow technology and Heat Recovery Ventilation units in a unique energy saving combination.

Using the LG Multi V Series 4 heat recovery VRF system LG, through distributor LGCC, has supplied a 32HP (89kW cooling/ 100kW heating), two module, inverter driven outdoor unit connected to ten large ducted internal units and two four way air discharge cassettes, connected through five heat recovery distribution boxes. LGCC has also supplied cooling for the server room.

In addition there are three LG Heat Recovery Ventilation units (ECO V) installed for the supply and extract of fresh air. These are supplied with CO2 sensors.

Remote zonal control is included but overall building control is achieved by LG’s AC Smart Intelligent Centralised controller. Remote return air sensors are also installed in zones to ensure accurate control of space temperature.

All LG outdoor unit coils are treated with LG’s Gold-fin™ epoxy coating as standard to inhibit corrosion. This will be particularly relevant at this site due to the air’s salinity and the memorial’s proximity to the coast.

“We hope that LG’s equipment will make the visits of the thousands of visitors in the years ahead, that bit more comfortable – whatever time of year they choose to visit – to pay their respects to the quite extraordinary men and women who kept the invaders at bay and showed extreme bravery – up to and including giving their lives for this country” says LGCC Director Jez Smith.

“As M&E consultants, Steadman Environmental Control is proud to have been associated with this iconic project, especially in this Battle of Britain 75th anniversary year,” said Martin Steadman.

Click on the images to enlarge

View LG's profile:

Free CPD Guide to energy labelling regulations

Story

Mitsubishi Electric has produced a free, CPD-accredited guide to the new Energy Related Products Directive or ErP (2009/125/EC), which is a key part of the European Union’s drive to encourage consumers to use more energy efficient products.

Mitsubishi Electric has produced a free, CPD-accredited guide to the new Energy Related Products Directive or ErP (2009/125/EC), which is a key part of the European Union’s drive to encourage consumers to use more energy efficient products.

The ErP Directive, which came into force at the end of September, now means that commercial and residential heating products will need to display an energy label, so that consumers can quickly understand the energy efficiency of the products they purchase.

A similar market transformation strategy has already proved highly successful with consumer goods such as fridges and freezers, where it is now very rare to find anything below an A rated product available on the high street.

To highlight the requirements under ErP Mitsubishi Electric has also released a short video which explains how the Directive is designed to help phase out lower performing products whilst having a positive impact on the emissions levels across Europe and increase the share of renewable energies by 20 per cent.

The dedicated video can be viewed at the company’s YouTube Channel and further information on the entire range of A++ heat pumps can be found on the dedicated Youtube channel at: https://www.youtube.com/watch?v=rk1ldYXNpuw&list=PLvcrLXkBScHpdC0WSvzpO3uvwawcNjpIr&index=10

The Directive is a two-part strategy. Firstly, the ErP requires manufacturers to produce energy-using products that meet stringent minimum performance standards. And secondly, these products must be clearly labelled using a standard methodology so that consumers can quickly understand the energy efficiency of the products they purchase.

The CPD Guide covers both main parts of the ErP: the EcoDesign regulations and the Energy Labelling regulations. The guide explains how the labelling is designed to help businesses and homeowners understand the benefits of each technology and focuses on the importance of ErP in relation to legislation such as the Renewable Heat Incentive (RHI).

For further information, visit http://bit.ly/1NBrWjl

Click on the images to enlarge

View Mitsubishi Electric's profile:

Making light work of brick soffits

Story

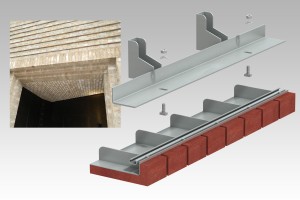

Creating flawless brick-faced soffits and lintels has now become much simpler and quicker, thanks to a new lightweight stainless steel based system developed by two industry-leading companies – brick support specialist Ancon Building Products and Ibstock Kevington –national manufacturer of brickwork and masonry special shapes and prefabricated components.

Creating flawless brick-faced soffits and lintels has now become much simpler and quicker, thanks to a new lightweight stainless steel based system developed by two industry-leading companies – brick support specialist Ancon Building Products and Ibstock Kevington –national manufacturer of brickwork and masonry special shapes and prefabricated components.

The new Nexus® system combines a specially developed Ibstock Kevington lightweight brick-faced steel unit with Ancon’s tried and tested MDC stainless steel bracket angle support system. The system offers contractors easier handling coupled with maximum adjustability, both vertically and horizontally, for quick and simple alignment on site.

The new system offers considerable benefits over traditional cast concrete alternatives – cutting weight by more than half, which in most cases will allow the brick-faced units to be installed without specialist lifting equipment, and significant savings in installation time – making it particularly appropriate for fast-track or time-limited projects.

Individual Nexus® units are designed and prefabricated off-site to suit different soffit dimensions, even modern deep soffits, so there is no cutting required on-site. They are simply offered up to the pre-fixed and pre-drilled Ancon MDC support system and then bolted into position using T-head bolts. The quality design allows units to be simply adjusted for perfect alignment and, once in position, all that is left is for the brick facing to be pointed for a seamless match with the main brickwork.

Nexus units can be fabricated using virtually any brick or masonry with the chosen product being specially selected and precision cut, generally from the same batch as the main façade to ensure a perfect visual match. Various brick patterns can also be specified to match individual project designs and styles.

All system components are of the highest quality, and engineered for economy and durability, with slips permanently bonded to the high grade stainless steel Nexus system using a BBA accredited bonding system. Nexus has been independently tested for long term durability by Lucideon, the independent global experts in materials testing, analysis and consultancy.

Ibstock Kevington Sales Director, Warren Dean said, “Nexus ® is an exciting new development that brings together the combined experience and expertise of two major companies – each market leaders in their own area. The advanced design will not only make it easier and quicker to specify and install modern brick-faced soffit and lintel features in a range of different building applications, but the two-part design means it will be far easier to achieve perfect alignment with the main brickwork façade.”

Further details and technical specifications for the Nexus® system are available in a new 4-page brochure, available to download from www.ancon.co.uk/Nexus.

View Ancon's profile:

Klober underlay for low pitch roofs

Story

A big problem when designing an extension is what to do where the roof pitch is limited by existing windows or pipework. Using a matching natural slate or clay / concrete plain tile has always been out of the question but Klober’s new underlay, Permo® extreme RS SK2 can be used at 12.5° with profiled tiles or 15° with flat tiles and slates.

A big problem when designing an extension is what to do where the roof pitch is limited by existing windows or pipework. Using a matching natural slate or clay / concrete plain tile has always been out of the question but Klober’s new underlay, Permo® extreme RS SK2 can be used at 12.5° with profiled tiles or 15° with flat tiles and slates.

This provides complete flexibility with tile selection and avoids the need to use unsightly, large format concrete tiles which just weren’t designed for small roofs. Permo extreme is tear-resistant and has double, self-adhesive strips which provide a permanent seal of laps. It provides immediate weather protection, water driven to the top of tiles being carried between the counter battens to the gutter. This is a job that standard vapour permeable underlay are not designed to do.

Permo extreme is best laid onto 12mm ply board or OSB sarking board. This makes sealing laps easy and avoids the need for care when determining drape between rafters. Standard counter battening is employed with ventilation at or near the ridge with cold roof construction. Klober Butylon tape must also be used beneath counter battens to seal around any nail penetrations.

View Klober's profile:

PODCAST: David Arendell interview with Nigel Pittman

Story

Listen to David Arendell interview with Nigel Pittman for BusinessNet Explorer on the subject of ‘Airtightness

View Klober's profile:

Sterling – the best just got better!

Story

One of the UK’s most popular cable management ranges has been updated to offer up to 15% more cable capacity, easier fitting and quicker, more secure installations that are even better looking.

One of the UK’s most popular cable management ranges has been updated to offer up to 15% more cable capacity, easier fitting and quicker, more secure installations that are even better looking.

The Sterling range by market-leader Marshall-Tufflex has been one of the market’s best selling trunking solutions for almost 25 years, with Sterling Profile 1 being the star performer of the range. To increase its appeal further Marshall-Tufflex designers have introduced a number of changes to the range:

- Improved base design for greater cable capacity

- New pre-punched knock-outs in the dividing wall, a time saving benefit for installers

- New single-piece moulded fittings for Profile 1 (coupler, end cap, internal and external bends)

- New moulded covers for Profile 1 flat tees and flat angles for easier installation and improved aesthetics

- More secure fittings due to improved clipping action

- Dividing fillets and cable retainers clip on more easily

- An improved RCD housing that clips directly to the central compartment of the Sterling base making installation much faster.

- A new faster to install RCD/MCB housing

The new streamlined base is compatible with existing Sterling fittings. However, the newly designed fittings are only compatible with the new base, the old base will be phased out over the next few weeks. Marshall-Tufflex has prepared a product compatibility sheet for wholesalers to enable them to assist customers with correct product selection and a product compatibility sheet for contractors, available from www.marshall-tufflex.com

The new, updated Sterling range is covered in detail in Marshall-Tufflex’s new Cable Management Catalogue. For a copy visit www.newcatalogue.co.uk, e-mail sales@marshall-tufflex.com or telephone +44 (0) 1424 856600.

View Marshall-Tufflex's profile:

Ohmmeter tests transformers faster and safer

Story

MTO250 series ohmmeters are readily portable mains powered instruments that have been specifically designed to accurately measure the resistance of all types of magnetic windings. Typical applications include the testing not only of transformers, but also of shunt reactors and the windings of rotating machines. In addition, MTO250 test sets can be used for performing many other types of low resistance measurements.

MTO250 series ohmmeters are readily portable mains powered instruments that have been specifically designed to accurately measure the resistance of all types of magnetic windings. Typical applications include the testing not only of transformers, but also of shunt reactors and the windings of rotating machines. In addition, MTO250 test sets can be used for performing many other types of low resistance measurements.

Validation of correct make-before-break operation of load tap changers is also supported and when this type of test is carried out, the instrument continually monitors transition currents, with high resolution, for each tap position, so that even slight discontinuities are detected and reported.

These innovative instruments support the use of test currents up to 50A, a feature which reduces the time needed to test high-current secondary windings by as much as ten times compared with standard instruments that have a maximum test current capability of 10A. When the tests are completed, an integrated demagnetisation feature ensures that the transformer can be returned to service without risk of excessive inrush current or other problems associated with core magnetisation.

Among the many safety features built into the MTO250 as standard is an auto-discharge function that operates when the test is completed, in the event of power loss or if a test lead is inadvertently disconnected. A safety interlock circuit is also provided, together with provision for the connection of a strobe beacon to provide a visual warning that a test is underway.

Internal data storage for test results is a standard feature, and the test sets can optionally be connected to a PC running Megger’s PowerDB software to provide full automatic control.

To complement the new MTO250 transformer ohmmeters universal Kelvin clamps with 100 mm adjustable jaws are available. These eliminate the need for multiple types of lead clips. Each Kelvin clamp also includes banana plugs for use on external probes for testing on terminal blocks.

To find out more click here

View Megger's profile:

The reinvention of large electrofusion couplers for quick and reliable connections

Story

Constructing large dimension pipelines is challenging and requires specific designs of the pipeline components. The GF Piping Systems electrofusion couplers for water and gas applications are therefore made for quick and reliable connection of your pipes and spigot fittings. Even under difficult site conditions the electrofusion couplers from GF Piping Systems provide a long lasting and safe connection thanks to the careful design.

Constructing large dimension pipelines is challenging and requires specific designs of the pipeline components. The GF Piping Systems electrofusion couplers for water and gas applications are therefore made for quick and reliable connection of your pipes and spigot fittings. Even under difficult site conditions the electrofusion couplers from GF Piping Systems provide a long lasting and safe connection thanks to the careful design.

Proven technologies

The electrofusion coupler product range of d355-d1200mm consists of two production technologies. Couplers with flex groove design (d900-d1200mm) ensuring a good jointing thanks to the special geometry and wall thickness.  Dimensions from d355 to d800mm are provided with the proven technology of active reinforcement (pipe in pipe).

Dimensions from d355 to d800mm are provided with the proven technology of active reinforcement (pipe in pipe).

Your benefits

- The extra-large inner diameter of the coupler permits easy assembly and can accommodate pipe ovality often found in practice.

- The smooth fusion zone (covered heating wires) guarantees an ideal fusion result.

- Reduced installation time without pre-heating or use of additional equipment.

- On path-limited fusion indicator each per fusion zone for immediate check.

- No special welding machine required, all current GF welding machines are suitable

- QR-code on each label links you directly to a dedicated web page enabling the online access of instruction videos and technical documentation.