Monthly Archives: July 2017

Saniflo helps burgeoning café culture

Story

Coffee culture in the United Kingdom has developed rapidly over the past five years, to the benefit of manufacturers of specialist coffee machines (for home and retail use) and specialist cafes and coffee shops. The UK retail coffee market has actually delivered strong growth for over a decade, allowing coffee chains and independent operators to spread rapidly across the whole of the UK.

The boom is partly attributable to the influence of American TV and the entrance of US-style coffee houses into the UK, with customers looking to emulate the cosmopolitan New York lifestyle. However, it is also the way we work, shop and spend our leisure time that accounts for the growing café/coffee culture. Mobile technology and the availability of free wifi has seen cafes become meeting, remote working and study places as well as places to socialise; particularly for families and women. More than a quarter of British adults visit a coffee shop once a week or more and over half those customers are women.

The rise of on-line shopping, too, has also contributed to the growth of café culture. Where people once spent their weekends trawling shops, now they are meeting up with friends in their local café.

Physical expansion by leading chains is a strong driver of growth, but the independents are also expanding strongly driven predominantly by interest in Artisan coffee shops. In the same way craft beer is helping to revive the brewing industry and speciality teas are helping to revive that oh-so British past time of tea drinking, it is the careful crafting of a quality coffee that is stimulating demand.

The trend is very much one that Saniflo in the UK can identify with. Over the last few years, there has been a noticeable leap in sales of commercial products for cafes and it is often a change in use of buildings and premises that necessitates a solution for waste water drainage. Former offices, showrooms, shops and even historic buildings are all being brought back to life to take advantage of café culture. And it is both independents and chains that are turning to Saniflo for a solution.

Take the Pato Lounge in Orpington High Street. As a redundant bedroom showroom, the building was falling into disrepair before being acquired by the Lounge Group – a chain that is renowned for its quirky use of pre-used buildings – and transformed into a large, comfortable café.

With its serving area in the centre of the space it needed a method of discharging water from sinks, dish and glass washers. A Sanicom 2 pump – installed under the counter – takes the waste water away through small bore pipework in the floor to the back wall where it is pumped up and across the ceiling to meet a soil stack in a central column. A further Sanicom located in the boiler room pumps condensated water and waste water from a large ice machine through the same ceiling void. A final Saniflo pump – the Sanicubic XL, is installed into a cleaner’s cupboard next door to the men’s and ladies bathrooms, from where it handles black water waste pumping it via the same pipework to the central column where it drops into a manhole and joins the mains drains in the street.

In Peterborough vacant offices and a former coffee shop was merged into one to create a two-story Argo Lounge. A full reconfiguration of the space meant that the plumbers used the same Sanicom and Sanicubic XL technolgy to discharge waste from the kitchen and bathrooms. Without the pumps the whole conversion would have involved more costly civils work; possibly prohibiting the viability of the scheme.

Three Cosy Clubs, in Birmingham, Leicester and Cardiff, have each been converted using similar Saniflo products turning an old bank branch, former knitwear factory and empty retail premises into large vibrant spaces that tap into the café culture trend.

Gatehouse Café, located in Walmgate Bar, York is a charming independent cafe nestled within the ancient walls of York. As the most complete of the four main medieval gateways into the city it is the only ‘Bar’ in the UK to retain its barbican, portcullis and inner doors. Using Saniflo products was the only affordable way of providing waste water discharge for the serving area and customer WC. A Sanicom in the kitchen and a Saniaccess macerator pump discharge waste via small bore pipework eventually ending up in the same cast soil pipe concealed within the toll bar walls.

Expanding chain, Patisserie Valerie, is opening new outlets at a rapid pace. The original concept of this store was to introduce continental style cakes to the brits, but as demand for additional products has grown each of the shops has invested in food and drink preparation areas; more often than not using Saniflo products to discharge waste water. In a large older building in Edinburgh a store basement has been transformed into a manufacturing premise, where handmade confectionary and cakes are made for distribution throughout Scotland. Saniflo products have made it possible to install sinks for food preparation areas with no major construction works. A Sanicom 1 – which can work with temperatures of up to 90°C – has been installed as the main pump station whilst two Sanispeeds – which are for lighter commercial applications – are processing water from a cleaners sink and dishwasher and pumping it up to meet the main soil stack.

So, the continuing development of the café culture in the UK, we can safely say, is being aided and abetted by leading plumbing brand, Saniflo, allowing a nation of tea and coffee lovers to indulge their passion in increasingly sociable spaces.

View Saniflo's profile:

Wakaflex lead-free flashing for ultimate performance

Story

Flashing work often requires a specialist roofer and can be both time-consuming and costly. Leadwork is also potentially hazardous to the installer if strict health and safety procedures aren’t adhered to.

This has prompted the introduction of a host of lead-free flashings, Klober Wakaflex® being both one of the longest established and highest performing. BBA-certified and with a 20-year guarantee, it is ideal for all roofing abutment work and roof types including clay, concrete, slate, metal and polycarbonate. Available in, light grey, anthracite, brown and terracotta (the latter two to special order), it has an aluminium ‘honeycomb‘ mesh embedded into UV-resistant butyl rubber which gives the product similar malleability to lead but with no scrap value. Unlike lead, it can be stretched by up to 50% in length and 15% in width and with no susceptibility to thermal movement it can also be laid in long lengths without fixing clips. With no need for forming or other specialist tools Wakaflex provides lasting performance regardless of detailing complexity and can be shaped around deeply profiled tiles or seal the top saddle and roof penetrations.

Wakaflex has a high-strength, self-adhesive Butylon® backing which provides immediate weatherproofing and on laps will also chemically bond to itself to provide a totally secure seal. It is environmentally safe, presents no contamination problem with water run-off and can therefore be used with rainwater harvesting systems.No heat, solvents, adhesives or other additional means of fixing are needed and installation can take place in temperatures from minus 40 – 100⁰C, normally without priming.

Wakaflex is available from builders and roofing merchants nationwide.

http://klober.co.uk/shop/product/wakaflex

View Klober's profile:

VMZINC launches Basic Competency Programme

Story

The continuing upsurge in use of zinc as a roofing and façade material has led VMZINC to introduce a ‘Basic Competency’ (BCP) training programme. Organised in conjunction with the CITB, Roofing Industry Alliance and FTMRC, the single-day module is linked to NVQ Level 2 and equates to the first stage of formal installer accreditation. Elements covered include roof design and construction, fitting, maintenance, tools, ancillaries and soldering. On achieving a ‘Pass’ an individual becomes eligible for a Red ‘Experienced Worker’ CSCS card if he has a ‘Working at height’ HSE test certificate. The holder has three years to register with a training provider to work towards NVQ and eligibility for a blue ‘Skilled Worker’ card. For details email vmzinc.uk@vmzinc.com or phone 01992 822288.

View VM Zinc's profile:

Power quality analyser gives Class A versatility

Story

The versatile MPQ1000 offers oscilloscope and DVM modes. In both modes it can monitor and record power, energy, RMS voltage and current, harmonics, inter-harmonics, harmonic direction, THD, TDD, flicker, unbalance, rapid voltage change (RVC), mains signalling and phase angle deviation as well as sags, swells and transients down to one microsecond. It also performs waveform analysis up to the 128th harmonic in real time.

Data gathered during testing can be recorded by simply pushing a button. The instrument automatically detects current clamps, recognizes the range, identifies the nominal voltage and sets the triggers, after which it verifies that the unit is properly connected before allowing a test to commence.

On-board data analysis is provided, and a removable SD card can be used to expand the instrument’s memory capacity easily and inexpensively. All data recorded can be viewed on the integral VGA colour display and can also be transferred to Megger’s power quality analysis software for more advanced analysis, reporting and archiving.

The PC-based software supplied at no extra cost with the analyser automatically creates custom configurations based on user requirements and facilitates tailored automatic data analysis. It also allows users to create their own analysis templates that can be loaded into the analyser.

To complement its versatile handheld MPQ1000 power quality analyser, Megger offers flexible current clamps that have four selectable ranges from 0 to 6000 A.

View Megger's profile:

Saint-Gobain PAM – Better BIM Data from Collaboration

Story

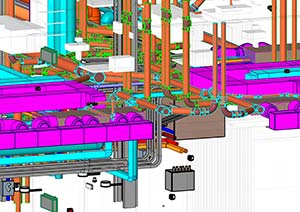

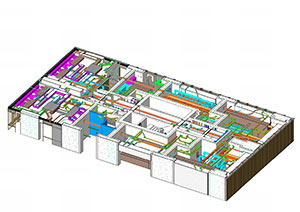

Saint-Gobain PAM has further developed its BIM library for its cast iron sanitary, soil and rainwater systems following collaboration with Hoare Lea.

Says Matthew Hassall, BIM Implementation Manager for Saint-Gobain PAM, “Ultimately BIM is only as good as the data that the manufacturer or supplier provides. It is now 12 months since BIM has had to be implemented on public sector projects and as a result industry is learning exactly what it wants from a library of products and systems. And the only way of achieving this is to collaborate with the supply chain and ask it what it needs and equally as important what is not required.”

Says Bogdan Pop, Public Health Engineer from Hoare Lea who has been collaborating on the company’s BIM development, “From our point of view we need to work with a manufacturer’s data, generic libraries just do not work. This in turn means that we need to work closely with suppliers like Saint-Gobain PAM to define exactly

what we need and to also remove unnecessary information.

“One very practical issue that we have come across relates to the software platform that many BIM libraries use. If a manufacturer does not put constraints on the dimensions of their products, then in theory you can design whatever you want; the problem is the design you have put together may include products that don’t exist in reality!

“Equally manufacturer’s mistakenly believe that they should include every detail in their 3D drawings, where often all we need are the dimensions. It means that the 3D drawings can be so large that it takes time to download and then input them into a design.

Continues Hassall: “BIM encourages us to share data, but the better question is defining exactly what data you need. We also recognise that these needs will evolve over time so on going dialogue with the supply chain is vital.”

Concludes Pop, “Developing a BIM library takes time and resource, sadly too many manufacturers have not invested and this only creates problems for the designer, installer and ultimately the final customer.

There is a real difference between the theory and what is actually effective when it gets down to working on a project.”

View PAM Building's profile:

FAKRO roof windows for Aberdeenshire Passivhaus self-build

Story

FAKRO FTT U6 and FTP U5 Electro triple-glazed roof windows were used on Carsluchie Croft, a Passivhaus project which maximises controlled solar gain The compact 1½ storey form reflects local vernacular architecture, with the angled bay on the south side designed as a dynamic element to contrast with the compact solid stone-clad form of the majority of the house. The FTT U6 has an exceptional U-value of 0.81W/m2K while the FTP U5 windows also had Z-wave connectivity enabling them to be operated from a laptop, mobile or tablet. All windows were also fitted with thermal flashings to enhance airtightness.

View Fakro's profile:

A luxurious prospect at New York’s Whitby Hotel

Story

New York City’s newest boutique luxury hotel makes a bold statement in upper midtown Manhattan, thanks in no small part to the extensive use of Crittall steel windows, doors and internal screens and partitions.

The Whitby is the second in New York opened by Firmdale Hotels whose owners, Tim and Kit Kemp, have already made a big impression back across the pond with several stylish and luxurious properties in central London including Ham Yard and Soho that also exemplify the use of fenestration by Crittall.

Opened in late February, The Whitby is described as a celebration of contemporary art and design boasting a stylish restaurant, bar and conservatory as well as a colourful library, several private event spaces and a state-of-the-art cinema. Each of the 86 bedrooms has been individually styled with Kit Kemp’s world-renowned mix of colour, pattern, texture, and art.

Located on West 56th Street between 5th and 6th Avenues, The Whitby is just two blocks from Central Park. It is surrounded by world-class department stores, luxury designer boutiques and is a short walk to Broadway.

Its location informed the specific choice of glazing. At Firmdale’s other NYC hotel, on Crosby Street, W20 steel windows were used. The Whitby’s position called for even higher acoustic attenuation and so Crittall MW40 fenestration was selected. These windows can accept up to 30mm thick glazing providing excellent acoustic as well as thermal performance.

Nevertheless, the sight lines are virtually the same as with the Corporate W20, that is to say the slender frames provide for maximum daylight while ensuring strength and security. All The Whitby’s guest rooms have floor to ceiling windows as a principal feature.

The ground floor meanwhile (the first floor in American parlance) also features interior screens and lobby doors by Crittall employing a single-glazed W20 profile. These are especially versatile for use in association with door hardware, closers, card entry equipment and so forth, dependent on their use. Facing the streetscape at ground level are Corporate 20 windows; large full panewindows that are even more robust than MW40s and which accept up to 28mm glazing.

The Whitby has been designed by New York architectural practice Stonehill &Taylor, which also designed the Crosby Street Hotel. The Whitby presents an elegant limestone façade rising 18 storeys and featuring several balconies and terraces that create a distinctive shape, stepping back as the building rises from street level.

The building harmonises with the architecture of the immediate neighbourhood, particularly Fifth Avenue. Says Paul Taylor, lead architect on the project, and president at Stonehill & Taylor:

“The Crittall steel windows are imbued with old world craftsmanship

and have the narrow sightlines that architects wish for.”

Contractors for the project were Flintlock Construction Services LLC.

View Crittall's profile:

Bona Titan – a new generation of powerful adhesives

Story

Bona, the wood floor experts, has launched Bona Titan, a new supreme performance, silane- based adhesive for high value projects, very wide or oversized solid wood boards – or any installation where the quality of the bond has to be guaranteed.

Bona Titan contains Titanium Technology – a revolutionary new formula comprising quadruple crosslinking that delivers superior durability and an unbeatable initial bond speed – even under challenging subfloor conditions.

Bona Titan can be specified with confidence to bond all types of wood flooring. Its superb shear strength makes installation easy and keeps even the largest, solid boards securely in place. If the subfloor is sound and dry, no primer is required.

The hard, silane-based formula contains no ingredients that can migrate after curing, which eliminates all risk of discolouration at the joints. The smooth, thick consistency makes it easy to use and produces stable ribs, an extremely high initial grab and zero risk of hollow spots. The bond strength of Bona Titan will not diminish over time so the stability of the floor is guaranteed for the long term.

Bona Titan meets ISO 17178 standards and, in line with Bona’s environmental strategy, is a safe, clean formulation which also carries EC1-R Plus, DIBt, Greenguard and A+ low emission certifications.

Bona Titan is compatible with underfloor heating and can be used directly on metal or tiles. Floors bonded with Bona Titan can be sanded after just 12 hours.

Further technical information is available at bona.com or from Bona’s technical department on 01908 525 161.

View Bona's profile:

Condair opens new Hamburg factory

Story

Global humidifier specialist, the Condair Group, has recently opened its newly built production, logistics and sales facility in Hamburg, Germany, marking a milestone in the company’s development. The state-of-the-art 13,000m² building centralises Condair’s European manufacturing operations, previously carried out in four regions across the continent.

Situated next door to Hamburg airport, the new Condair facility is also close to the motorway and harbour, and incorporates the latest in energy saving building services technology.

Oliver Zimmermann, Condair’s CEO, explains, “Norderstedt in Hamburg offered us the perfect logistical location. Placing our production facility close to our core central European markets, with such convenient transport links, shortens our delivery channels and results in quicker delivery times. The consolidation of four different European production centres into a new high-tech facility not only makes Condair more streamlined and cost-effective but also enables us to improve our processes and quality.

“The excellent opportunities offered by the new location are essential for the far-reaching restructuring of the company and it is with great pride that we open this new chapter in the Condair success story.”

Central to the design of the Condair building was a focus on energy saving technology. The German Energy Saving Ordinance (EnEV) 2014 and a maximum heat demand of just ≤35 kWh/(m²·a) were selected as minimum standards for the building. Once completed, the building actually performed 50% better than the target standard and almost achieved Passive House standard at full capacity, which is an outstanding result for a production facility with offices.

Geothermal power is harnessed through the use of two 28m high-performance energy piles, and roof-mounted photovoltaic panels generate nearly all the required electrical energy for the site. A hybrid ceiling system, from the sister company Barcol-Air, provides cooling and heating, as well as acting as a thermal storage system in combination with the building shell.

Being the world leading humidification specialist, maintaining a healthy indoor climate of 40-60% relative humidity at 22-26°C was of utmost importance for the Condair development. Humidity control is primarily delivered using a Condair GS, gas-fired steam humidification system, with energy being transferred from its flue gases to the incoming fresh air via a heat recovery system for improved efficiency. A Condair ME evaporative humidifier is providing indirect evaporative cooling by humidifying the exhaust air and pre-cooling the incoming fresh air by several degrees with a heat recovery system. Other direct room humidifiers are also providing localised humidity control and evaporative cooling around the building.

The current internal conditions are presented for all to see on a digital wall display, which also shows the atmospheric conditions at all of Condair’s 16 other international offices around the world. This is part of the “learning zone“ at the facility that allows visitors to explore the complex nature and importance of humidity control within the modern indoor environment. Alongside video walls and demonstration areas there is a full size air handling unit with internal holographic representations, showing how each type of humidifier technology operates and conditions the air stream in various HVAC scenarios.

Condair Group is the world’s leading specialist in humidification and evaporative cooling, with energy efficient, hygienic and innovative technologies for commercial, industrial and heritage applications. Condair is acting directly in the UK through Condair plc, which offers system design, manufacture, supply, installation, commissioning, maintenance and spares. Condair in the UK is the new name for JS Humidifiers following the organisation’s rebranding in October 2014.

View Condair's profile:

Fire safety with Crittall Fabrications glazed interior partitioning

Story

Architects and designers planning a fire escape route within their buildings can now specify Crittall Fabrications glazed partitions and doorsets.

As the use of such glazed partitioning to transform the interiors of both new build and refurbished properties gains in popularity, in commercial, retail, hotel and educational establishments in both the UK and the US, Crittall Fabrications offers the ideal solution.

Its extensive range of steel fire rated glazed doorsets, flush fitting steel fire rated doors, and fire rated steel glazed partition walling provides a winning blend of elegance and peace of mind. All the company’s glazed partitioning products comply fully with the appropriate BS and EN standards.

As accredited manufacturers Crittall Fabrications can assist the creation of fire route plans by supporting design ratification, technical information, test certification and documentation. Clients may choose supply-only, or a full design and installation service which is offered through The Crittall Group

Fire rated steel doorsets and steel glazed partitioning can be supplied as single or double-leaf doorsets, with a range of latches or handles, with sliding doors, a break-in/break-out emergency function and with fire ratings that range from 30 to 120 minutes integrity or 30 to 60 minutes integrity and insulation.

All Crittall Fabrication fenestration and doorsets are known for their combination of elegance and toughness thanks to the slim profile and inherent strength of steel components. To this is added the factory-applied powder coating that provides an extremely hard-wearing, highly durable, maintenance-free finish.

The doorsets and partitioning compliments all other product ranges within the Crittall group of companies so they blend consistently and aesthetically with the choice of external glazing.