Monthly Archives: November 2017

Saniflo launches Kinerock shower tray with patented mineral material

Story

Saniflo – the UK’s leading designer and manufacturer of macerators, pumps and shower cubicles – has added a new contemporary shower tray featuring its patented mineral material, the Kinerock, to its portfolio of bathroom products.

The Kinerock is no ordinary shower tray. Not only is it made from an extremely durable and versatile patented mineral material, it can be easily cut to measure to fit into any shower area. Available in a variety of standard and large sizes and colours to suit most tastes and requirements, the anti-slip surface reduces the risk of falling in the shower.

Kinerock is made from a mineral filler and acrylic resin. This means it is light and easy to cut to ensure a perfect fit. The gelcoat surface ensures it is durable and highly resistant to scratches and damage.

The Kinerock is an extremely comfortable, safe and versatile shower tray. The textured material offers good grip adding a feeling of security and reducing the risk of falling, and at just 40mm thick, the Kinerock offers easy access into a shower area. The material ensures the surface is not cold to touch for your comfort whilst showering.

Easy to clean and maintain, the Kinerock is kept looking pristine with just soapy water and the waste grill can be easily removed for deep cleaning.

Ann Boardman, Saniflo UK Head of Marketing and Product Development, comments: “There’s a growing trend for ultra sleek, low level shower trays due to the popularity of contemporary and easy access bathrooms. The experts at Saniflo have really come up trumps with Kinerock. It looks amazing, it feels amazing and it is secure underfoot, plus it is easy to fit and care for. We think our patented mineral material is the way forward for shower trays. End users want versatility, and any shower tray that can deliver that, such as the new Kinerock, is a bonus.”

To order your copy of the new Saniflo domestic and commercial product catalogue visit www.saniflo.co.uk

View Kinedo's profile:

NEW TROX PWX FANCOIL RANGE REDEFINES ENERGY EFFICIENCY AND ACOUSTIC PERFORMANCE

Story

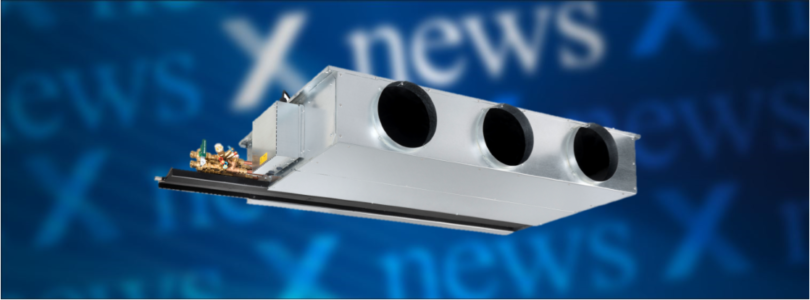

TROX has announced the launch of a major new fancoil range – the TROX PWX Series – which brings to the market a 25% to 35% energy efficiency improvement over alternative models, with outstanding acoustic performance, and BACnet-enabled integrated controls packages as standard.

The launch of the new TROX PWX fancoil range follows an extensive research and development programme in which the company rejected incremental product enhancements in favour of a comprehensive rethink of fancoil technology. The new products have undergone thorough in-house testing, using TROX’s test chamber (constructed to comply with ASHRAE 79, BS1397 and EUROVENT 6/3), in addition to extensive corroboration of results at an independent test facility. As a result, specifiers are able to input exact performance criteria for an extremely wide range of thermal and acoustic scenarios when planning their air conditioning schemes, instead of having to rely on less reliable ‘anticipated’ or ‘expected’ data. The TROX PWX range is therefore able to speed up the specification of projects significantly, reduce levels of risk, streamline installation and commissioning, and provide valuable environmental and cost benefits.

Whilst the basic physical dimensions of the TROX PWX units have been kept the same (270mm deep) to meet market requirements, every aspect of the thermal, electrical and acoustic performance of these models has been redesigned. With new inlet attenuators, inlet plenums and discharge attenuators, the units feature completely redesigned key components capable of achieving outstanding performance across a wide range of applications.

The SFPs across the range comply with and exceed Part L requirements, with typical values between 0.15 to 0.25 W/(l/s) at 30 Pa ESP, with a Guide NR of 35.

The environmental performance of the fancoils has been developed in conjunction with the full range of TROX air terminal device options. TROX’s unique ‘One Stop Shop’ solution enables correct selection of air terminal devices to be tailored to each fancoil. This optimises potential energy savings without compromising air distribution (a factor very often overlooked when specifying the systems independently). The ability to source the entire system from a single supplier also enables specifiers to optimise the performance of the fancoils in VAV (variable air volume) systems. The specification process has been speeded-up by the introduction of sophisticated new in-house product selection technology. This makes it possible to identify the most effective combinations of fancoils, grilles and diffusers more quickly, making it possible to specify fancoils for entire projects in just minutes, rather than hours.

The TROX PWX fancoils are supplied with specially-designed on-board controls packages, as standard. Two different STD controls packages are offered:

- BACnet control, offering the full flexibility of uniquely addressed terminal units, which interface with Building Management Systems (BMS) and provide feedback on each unit’s performance.

- TROX can also offer standalone controls that allow user control of individual units where no BMS is present.

To complement these control packages, TROX is also able to offer a full water-side control package which has been designed to work seamlessly with either control option.

These control solutions provide a number of valuable benefits. Project lead-times can be reduced significantly, as all wiring diagrams are pre-designed and readily available. This reduces the time and costs associated with additional electrical scheme design or expensive customisation of BMS programming. Specifiers also have the peace of mind that the controls technology has perfect compatibility with the fancoil units, and has been developed specifically to optimise performance in a way that is hard to replicate with ‘bolt-on’ controls.

A key factor in the development of the TROX PWX Series has been the thoroughness of testing, which removes the project risks associated with incomplete or uncorroborated performance data. By thorough testing in-house using its own BSRIA type test rig, and by sourcing detailed external data for the fancoils from extensive independent testing, TROX is bringing to the market a range of products with unrivalled, verifiable, specification data. Care has been taken to test the units at specified 30 Pascal external static pressures (ESPs) and to provide exact performance figures. This improves on industry practice where lower external static pressures might be employed during testing, culminating in misleading results.

This rigorous testing of electrical and thermal performance has been matched by extensive independent acoustic testing. The acoustic testing, carried out in accordance with BS EN 16583:2015, covers the entire PWX range, including all available fan configurations across the full operating range.

Such detailed acoustic analysis allows precise selection of units to suit the customer’s requirements and is complemented by TROX’s new selection process, enabling user adaptation of project-specific finishes that may affect the resultant room NR level. As the suspended ceiling finish has such a big impact on the room NR, TROX has worked closely with Armstrong Ceilings to pre-programme tested ceiling tile SRI values into its new calculation programme to ensure the correct acoustic assumptions are used.

The new TROX PWX Series is designed to replace the company’s earlier fancoil models. The range includes 6 different physical sizes of unit, with 9 possible airflow configurations and 16 different fan options. The units are designed for 4-pipe heating and cooling, 2-pipe cooling, or electric heating as standard. As TROX is able to supply almost every element of an air handling system, from AHUs to air terminal devices, key advantages for system designers and specifiers include the possibility of ordering the fancoils alongside VAV components and ATDs, from a single supplier, for a perfectly-integrated solution.

View TROX UK's profile:

Vandex BBA systems now available from Triton

Story

Vandex waterproofing products, including BBA certified Vandex BB75 and BBA certified Vandex Super, are now available from Triton Systems. The introduction of these two ‘Type A’ cementitious waterproofing systems to Triton’s range will enable specifiers to source, from a single point of supply, all the waterproofing materials they need for projects where a BBA certified, combined waterproofing system is required.

Vandex BB75, a ready mixed slurry coating, is designed to waterproof vertical and horizontal concrete and masonry substrates, including awkward areas in vaults and cellars where a cavity drained system would not be appropriate.

Vandex Super is an ‘active’ formulation, designed to waterproof foundations, slabs, lift pits and construction joints by combining with the free lime and moisture present to form insoluble crystalline complexes that block capillaries and minor shrinkage cracks.

Other Vandex products, including elasticized slurries and repair mortars, will also be available through Triton from now on.

Neil Taylor, Sales Director at Triton, said, “The introduction of Vandex products to our range means we’ll be able to supply a much wider choice of Type A waterproofing systems to our customers, in particular for where a BBA certification is required for third party building warranties such as NHBC and Premier. Our Vandex products will of course be backed up by the expert technical support architects and contractors have come to expect when sourcing waterproofing systems from Triton.”

View Triton Systems's profile:

Viva Sanitary launch improved Skylo UNIFILL

Story

The new and improved UNIFILL is the flagship product in this range and is a patented universal WC fitting which was developed for simpler installation.

Viva Sanitary, a leading manufacturer and supplier of sanitary fittings, has recently launched its new range of Skylo toilet cistern fittings in the UK. The new and improved Skylo Dual Entry 4 in 1 Fill Valve is the flagship product in this range, and we are proud to introduce it to you here.

The Dual Entry, a patented universal WC fitting, was developed to allow for quicker and simpler installation. The product was an instant success with stockists and installers alike. It meant stockists could reduce the range of fittings they stocked, which saved vital space and reduced the amount of cash tied up in product. It also gave installers peace of mind knowing that one valve could cover a wide variety of applications.

Even with the success of the first version, Viva didn’t rest on their laurels. Instead they looked for ways in which the valve could be improved, and worked with important feedback from customers to help design and implement the changes, creating the new and improved version that we offer to you today.

The new Skylo Dual Entry 4 in 1 Fill Valve which launched in September 2013 is even easier to install and has greater functionality. As with the previous version, it caters for both bottom and side entry applications and again it comes with 1/2″ and 3/8″ adaptors, incorporating four valves in one. One of the biggest improvements to the valve is the way it is adaptable for both bottom and side entry; the installer selects the application and screws the thread into the sprung loaded opening. There is no requirement to close off the unused opening, which makes installation DIY friendly.

This image shows the valve open when thread is connected.

The float size has also been reduced and also comes with a Delayed Fill. It is able to rotate 180° so the valve can fit into the tightest of spaces and can perform even more jobs. In the event that maintenance is required, the easy-access mechanism allows for speedy and hassle-free diaphragm replacement.

If you have been won over by the benefits of using our new and improved Skylo Dual Entry 4 in 1 Fill Valve then check out our installation video:

If you have any questions, please feel free to contact our customer service team who will be happy to assist you and if you like this article don’t forget to share.