Monthly Archives: May 2018

Eco-friendly homes waterproofed by Triton Systems

Story

Waterproofing products supplied by Triton Systems were specified to waterproof eight, eco-friendly, new build homes. The individual properties sit embedded in a hillside with panoramic views across the coastline and the city of Sunderland.

Waterproofing products supplied by Triton Systems were specified to waterproof eight, eco-friendly, new build homes. The individual properties sit embedded in a hillside with panoramic views across the coastline and the city of Sunderland.

Triton’s Area Manager, Malcolm Cook, recommended the use of Triton TT Admix (http://www.tritonsystems.co.uk/prod2.php) to deliver a Type B waterproofing solution that would deliver a speedy and simultaneous method of waterproofing and construction. The product was used at the time of batching for all concrete in the slabs and ICF walls. The water-resistant concrete was then vibrated until all voids were eliminated. As part of the TT Admix system, pre-formed Triton TT Waterstop and Triton TT Swellmastic S2 hydro-reactive expansion sealant, were also specified to seal the construction joints.

When TT Admix is added to the concrete mix, its active chemicals react to generate a non-soluble crystalline formation which seals the concrete itself against the penetration of water or liquid, and protecting it from the deterioration effect of harsh environmental conditions. Other benefits include its ability to withstand extreme hydrostatic pressure (up to 12 bar) and reduced shrinkage and cracking. The active components of the TT Admix are reactivated within the cured concrete should minor cracking or movement occur when water is present. The product is compatible with cement blends containing pulverised-fuel ash; ground granulated blast furnace slag and silica fume blends.

Triton TT Vapour Membrane was then spray applied to the ICF formwork as the primary waterproofing layer. This Type A waterproofing system is a ready blended coating that once cured, also provides a Methane and Carbon Dioxide barrier. It can be retro-applied to concrete, masonry and brick substrates or used as an alternative to sheet membranes in new construction.

View Triton Systems's profile:

Bona introduces wood floor styling at Clerkenwell

Story

As a showroom partner, wood floor specialist, Bona, through twice daily talks, will introduce the Clerkenwell community to its new ‘Inspiration’ wood floor styles, designed to transform the look of tired, existing wood floors or to embellish unfinished new ones.

As a showroom partner, wood floor specialist, Bona, through twice daily talks, will introduce the Clerkenwell community to its new ‘Inspiration’ wood floor styles, designed to transform the look of tired, existing wood floors or to embellish unfinished new ones.

Created by Bona in collaboration with internationally recognised trend analyst, Cay Bond, each of the 17 new looks can be achieved using a combination of Bona’s sanding and brushing methods to enhance the grain, followed by treatments with the company’s waterborne lacquers, oils and colours. The styles, Nordic Shimmer, Garden Atmosphere, Malibu Dreams, Touch of Grace and New Modern, include everything from dark, rustic floors to floors with a pale, lacquered finish.

Floor owners are often simply not aware of how an existing wood floor can be transformed, giving a room or space a completely new look and feel. From a sustainability perspective it makes sense too – the old floor has already been manufactured and transported.

A campaign starts on June 1st using social media, print and online advertising to target and inspire floor owners. Contractors will be able to use the professional pages at bona.com to see how the individual looks can be achieved, and samples and beautiful inspirational brochures will also be available for designers, architects and flooring contractors to leave with their clients.

Register for twice daily showroom talks entitled ‘Inspiration through renovation – how to achieve contemporary trends on existing wood floors’ at this link – https://www.bona.com/en-GB/Professional/Support/Events/Clerkenwell-Design-Week/ or via Bona’s Showroom page at clerkenwelldesignweek.com

View Bona's profile:

Expansion into advanced composites brings third Queen’s Award for Ancon

Story

Structural fixings manufacturer, Ancon, has won a 2018 Queen’s Award for Enterprise in the Innovation category, for the successful introduction and on-going development of its advanced composite, low thermal conductivity, Teplo wall tie range.

This is the third time that Ancon has been honoured in this prestigious award scheme that rewards outstanding achievements by UK businesses; it follows Queen’s Awards for International Trade in 2015 and Innovation in 2012.

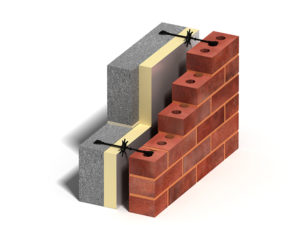

Teplo wall ties are manufactured from continuous basalt fibres set in a resin matrix; a fibre-reinforced polymer that is 70 times more thermally efficient than steel. When used to join the two leaves of a cavity wall, this material virtually eliminates cold bridging across the insulated cavity. Launched by Ancon in 2010 as part its market leading wall tie range, Teplo has had a major influence on the growth of low energy housing in the UK and Ireland, and helped future-proof traditional masonry cavity wall construction techniques, by minimising insulation thickness and wall footprint.

Whilst Ancon’s first Queen’s Award for Innovation in 2012 recognised the company’s in-house development of a unique lockable concrete-connecting steel component, this second Innovation award has been won jointly with its external strategic partner in this advanced composite development, MagmaTech.

Head of Marketing and Innovation at Ancon, Annabelle Wilson, says “Ancon launches a number of new and improved structural fixing solutions every year and invites ideas into our innovation process from both inside and outside the company. We saw potential in this new material immediately, and over the last eight years have committed our business resources to improving and extending the Teplo wall tie range as part of the Ancon product portfolio, bringing the benefits of advanced composites to mainstream UK construction.”

Today, the Teplo wall tie range includes Teplo-L suitable for surface-fixing in timber frame construction, the Teplo-BF with moulded safety ends that improve buildability particularly in lime and other slow-setting mortars, and the Teplo-BFR which can be resin-bonded in existing walls for retrofit applications. Teplo has been used in numerous ground-breaking developments, including the UK’s first masonry cavity wall ‘PassivHaus’, the UK’s first zero-carbon retrofit and the largest building in the UK built to the ‘Passivhaus’ standard, the University of Leicester’s Centre of Medicine.

Ben Williams, MagmaTech’s Managing Director says “Ancon has proven to be an exceptional partner for cutting edge innovation. They embraced a concept that was potentially disruptive to their existing stainless steel business, promoting it with passion and commitment. Taking a truly innovative energy-saving product to this level of market acceptance in just a few years is a truly outstanding achievement, surpassing our expectations.”

Commenting on their latest triumph in the Queen’s Award programme, Ancon’s Managing Director, Stuart Maxwell, says “Winning three Queen’s Awards in seven years is an extraordinary achievement and reflects the level of professionalism with which Ancon employees, in all areas of our organisation, go about their daily business. Our focus on quality and innovation, combined with a single-minded determination to excel in everything we do, not only underpins our brand reputation in the UK but its growing significance worldwide. It is another very proud day for everyone connected with Ancon and I thank our employees – both home and abroad – our customers and our suppliers for their continued support.”

Later this year the Lord Lieutenant of South Yorkshire will visit Ancon’s head office and main manufacturing site in Sheffield and officially present the 2018 award on behalf of HM The Queen. Ancon representatives will also attend a royal reception at Buckingham Palace this summer, hosted by HRH the Prince of Wales and other senior members of the Royal household.

Later this year the Lord Lieutenant of South Yorkshire will visit Ancon’s head office and main manufacturing site in Sheffield and officially present the 2018 award on behalf of HM The Queen. Ancon representatives will also attend a royal reception at Buckingham Palace this summer, hosted by HRH the Prince of Wales and other senior members of the Royal household.