Monthly Archives: March 2021

CONDAIR LAUNCH NEW EVAPORATIVE HUMIDIFIER

Story

Humidity control specialist, Condair, is launching the Condair MC, a new in-duct evaporative humidifier and cooler. A single unit is capable of supplying up to 360kg/h of humidity and around 245kW of adiabatic cooling to an air handling unit (AHU) from less than 0.15kW of electrical energy.

The Condair MC consists of an evaporative module and hydraulic unit, which sits inside the AHU, and a control panel located outside. The evaporative module is a wall of corrugated glass fibre media cassettes, with stainless steel frames, through which the air flows. The hydraulic unit pumps water to the top of the evaporative module to wet the glass fibre media and humidify the air flowing through them.

Dave Marshall-George, UK & IRE Sales Manager at Condair, commented, “We are delighted to be adding the Condair MC to our evaporative humidifier range. With every kilogram of humidity provided by an evaporative humidifier around 0.68kW of adiabatic cooling is also achieved. This sustainable cooling technology presents great potential to reduce the carbon footprint of our built environment. We are seeing more and more air handling unit manufacturers and M&E consultants incorporating direct and indirect evaporative cooling strategies into their AHU designs. The new Condair MC incorporates many innovative hygiene, installation and operational features, making it an ideal solution for evaporative cooling or adiabatic humidification.”

Evaporative humidifiers can provide humidification during the winter to raise an indoor humidity level, as well as offer adiabatic cooling during the summer to economically cool an internal environment. The main advantage over other in-duct spray humidifiers is that evaporative units can operate on mains water, without the need for a filtered RO water supply. This greatly improves the water efficiency of the system. The benefit over in-duct electrical steam humidifiers is a reduction in energy cost. The energy required to evaporate the water can be taken from the airstream, if excess heat is available, or from cheaper gas-fired pre-heating.

The Condair MC incorporates robust glass-fibre evaporative media, which has a long operational lifetime and is impregnated with antimicrobial additives for hygienic operation. The evaporative media has been independently tested and found to be non-particle releasing, and Euro Class A2-S2-D0 (UL 900) flammability rated.

As with any adiabatic humidifier, hygiene control is paramount and the Condair MC has automated flush and drain cycles, to ensure the water in the system is fresh and hygienic. Any sustained period of non-operation will initiate a drain of the system to ensure water cannot stagnate. An optional submerged UV sterilisation system is available to kill micro-organisms in the water and further enhance hygienic operation.

The hydraulic module can incorporate up to three low energy, long-life pumps, with frictionless magnetic impellors that are almost silent in operation. The pumps provide water to the evaporative module in stages, allowing more accurate control over humidification than single stage systems. As the humidifier has multiple pumps, its energy consumption is proportionate to output. Electrical consumption ranges from just 74W, with only one pump operating, to 145W with three.

The Condair MC’s control panel provides PCB controlled operation of the humidifier, BMS connectivity via Modbus, as well as LED indication of operational status and fault diagnostics.

The Condair Group is the world’s leading specialist in humidity control and evaporative cooling technologies. Condair offers free expert advice and system design, as well as manufacture, supply, installation, commissioning, maintenance and spares. The company operates globally with manufacturing facilities in Asia, Europe and North America, has Condair sales offices in 22 countries and international sales partners in more than 50 other regions.

View Condair's profile:

Helping to preserve an industrial landscape

Story

Two former furniture factory buildings in East London have been transformed into high-end apartments with the help of Crittall windows.

Long Street in the Hackney conservation area was a key component in Shoreditch’s industrial heritage. The area was once the heart of the capital’s furniture trade and, following the Second World War when large tracts of land were earmarked for comprehensive re-development, the then London County Council sought to preserve the district’s characteristic built environment as well as local business by constructing what were termed ‘flatted factories’

The four-storey structural steel-framed blocks were built in Long Street in 1959 with plenty of natural daylight and generously sized lifts for transporting uncut sheets of plywood to the upper floors.

The two blocks now form part of a luxury residential development, Long and Waterson. Architects Fletcher Priest have taken their design cue from the industrial lineage of the area, retaining original external brickwork and window settings and adding two rooftop penthouse levels creating a total of 71 apartments.

Crittall Corporate W20 and MW40 systems were specified, in fixed and opening format together with Crittall cold form tubular doors that meet the RC3 burglary resistance security standard; a choice that preserves both the original appearance and the industrial heritage of the area.

View Crittall's profile:

Bradite launches One Can Matt

Story

Specialist coatings manufacturer Bradite is doubling the appeal of its highly successful One Can Eggshell by releasing a Matt version of the water-based all-in-one primer and finish paint.

Offering the same full adhesion, anti-corrosive and stain-blocking qualities as its eggshell cousin, One Can Matt has been formulated using the same innovative technology but now offers a flat, matt finish for both internal and external use offering improved faster drying, application and durability.

One Can Matt launches at the beginning of March, two years after the launch of the original eggshell version.

Bradite National Sales Manager James Burton explains: “The introduction of this new offering provides the decorator with a greater opportunity to make use of the advantages of One Can. Its formulation provides all the benefits of One Can but with a flat matt finish. It is touch dry in just half an hour and re-coatable in one hour, meaning, if needed, three coats can be applied in a single day.”

One Can Matt was developed following customer feedback requesting a hard-wearing, scrubbable finish for a range of applications, from high traffic wall areas, masonry and internal trim and furniture, where a flat finish was preferred but all the advantages of One Can were maintained.

The paint combines a primer, undercoat and topcoat in just one tin and can be used as any one of these or all three. It is water-based, therefore has no smell, is stain locking and will help hide a wide range of blemishes including water, nicotine, rust or resin bleed.

It is ideal for priming difficult-to-paint surfaces both porous and non-porous including timber, ceramic tiles, glass, powder-coatings and many plastics including PVCu. It works as both an adhesion primer and sealer, is anti-corrosive and can be applied direct to both ferrous and non-ferrous metals.

As with the Eggshell finish, One Can Matt can be brush, roller or spray applied and is available in a full range of BS, RAL and NCS colours.

Its use, says James Burton, means less paint, less time, less waste, and more profit.

View Bradite's profile:

Crossrail systemwide contractor ATC reaches for new heights with the help of Bilco UK

Story

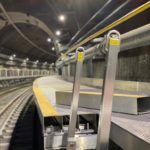

With the new Elizabeth line set to deliver a 10% increase in rail capacity across central London, the project will provide a high frequency service that reduces journey times and creates new travel opportunities by linking 41 stations across 100 kilometres.

As part of the landmark construction project, over 42 kilometres of new tunnels, 50 kilometres of new track and 10 new stations are being developed in conjunction with major upgrades to the existing infrastructure.

Throughout the construction stages of the central section, which spans from Westbourne Park to Plumstead and Pudding Mill Lane, over 350 of Bilco UK’s innovative aluminium Ladder Up® Safety Posts have been specified by Crossrail’s systemwide contractor Alstom TSO Costain Joint Venture (ATC Systemwide) to provide safe and secure access.

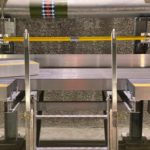

Weighing just seven kilograms due to the milled aluminium construction, the resilient Ladder Up® Safety Posts will provide engineers with unobstructed access to the walkways when conducting essential maintenance throughout the tunnels, once the line is operational.

Once fully open, the Elizabeth line will provide an additional 1.5 million people with access to central London within 45 minutes, covering Reading and Heathrow in the West, right through to Shenfield and Abbey Wood in the East.

The specification process, managed by Construction & Rail Contractors McNealy Brown, focused on the requirement for durable yet functional access solutions that would consistently provide a safe and direct step through onto the walkway, without impacting on the surrounding electrical services.

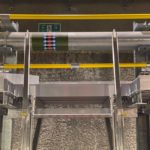

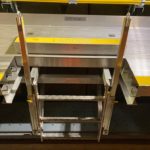

The unique and high quality construction of the Ladder Up® Safety Post fulfilled each requirement of the brief. This includes features such as the innovative telescopic post, which mounts permanently to the top two rungs of any fixed ladder to provide a secure handhold that enables the user to enter or exit the opening in an upright and balanced position.

Clive Burfoot, Contract Manager at McNealy Brown, said: “When we first began researching potential access solutions for the Crossrail project’s central section, it became clear quite quickly that the Bilco UK Ladder Up® Safety Post was the only product available on the UK market that would fulfil our extensive list of requirements.

“The telescopic extension was one of the main benefits that secured its specification for this project, as it enables the Ladder Up® safety post to be both retracted and extended, a key function that wasn’t available with any other access solution.”

Each ladder has been installed with two Ladder Up® Safety Posts, which are located on either side of the ladder to provide the direct step through onto the walkway for increased safety and efficiency.

The installation process, which has been managed by ATC Systemwide, will provide secure access throughout all essential areas of the central section, including at either end of every station and at additional strategic locations.

Vimesshen Ravindran, Senior Mechanical Engineer at ATC Systemwide, said: “The lightweight construction of the Ladder Up® Safety Posts ensured the installation process was quick and easy, resulting in no unforeseen issues on site. When the system retracts, the high quality spring-balance and convenient lever release provides a controlled means of lowering into its retracted position. This delivers enhanced ease of operation, ensuring long term suitability and usability for the engineers when undertaking future maintenance tasks.

“The Ladder Up® Safety Posts will play an essential role in ensuring the central section of the Elizabeth line continues to run at the highest standard, so it was crucial we specified access solutions that would facilitate the continued maintenance of the line, safely and efficiently.”

The telescopic tubular section automatically locks when fully extended, while the adjustable mounting hardware accommodates any ladder rung size or spacing. The corrosion resistant construction can also withstand the demanding environment of the London underground system, ensuring its successful operation for years to come.

Darren Waters, Managing Director of Bilco UK, said: “We are extremely proud to have been involved in the UK’s high profile Crossrail infrastructure project and have worked closely with McNealy Brown and ATC Systemwide throughout every stage of the specification and installation stages.

“This has ensured our unique Ladder Up® Safety Posts have fulfilled each individual requirement of the central section of the Elizabeth line, from security and ease of usability, right through to long term durability. We look forward to seeing the completion of the Crossrail project as our innovative access solutions play a vital role in ensuring its safe and successful operation.”

Aiming to make travelling throughout the capital easier, quicker and less crowded for passengers, the Elizabeth line will not only reduce the strain on London’s transport network but transform the way passengers experience and interact with the city and its suburbs.

For further information on Bilco UK’s complete range of roof access solutions, visit www.bilcouk.co.uk or call 01284 701696.

View Access 360's profile:

Profab Access proves its worth at One Bishopsgate Plaza

Story

Situated in the centre of the City of London, One Bishopsgate Plaza is one of the first high-rise residential and hospitality developments to be built in the capital for a number of years.

Once construction has been completed, the flagship 43-storey tower will house London’s first luxury 5* Pan Pacific Hotel, which will comprise of 237 rooms, an indoor swimming pool and a 370 capacity Pacific Ballroom, Square Mile’s first dedicated ballroom.

From levels 21 to 41, the development will house 160 luxury one, two and three bed residential apartments, or ‘Sky Residences’, which will boast panoramic views of some of London’s most iconic landmarks.

As part of the construction process, over 200 steel riser doors from Profab Access in a range of door leaf configurations and sizes from its 4000 Series, combined with over 300 bespoke ceiling panels from its 7000 Series, are currently being installed throughout the entire tower by BDL Dry Lining.

Specified due to their impressive seamless integration into masonry walls, shaft walls and drywall partitions, the riser doors provide discreet and secure access that won’t impact on the overall interior design scheme of the development, a main consideration for the public and private areas of the hotel.

The 4000 Series’ third party CERTIFIRE bi-directional certification from Warrington Fire was also a leading factor for specification, as the riser doors are fire tested from both sides to two hours, providing the highest standard of evidence for fire safety performance.

All of the doors were supplied with comprehensive CERTIFIRE accreditation documentation as evidence of Profab Access’ up to date fire testing, providing both the specifiers and contractors responsible for the development with absolute confidence in the performance of the critical fire integrity products.

The 4000 Series is the only riser door in the UK to be independently bi-directionally fire tested and certified by an accredited third party, to ensure legal compliance.

A combination of one and two hour fire rated riser doors were chosen to be installed throughout all residential and communal areas of the building to not only achieve compliance with current regulations by eliminating the spread of fire throughout the building for the specified durations, but sufficiently future proof the building for years to come.

The bespoke Profab Access 7000 Series Ceiling Access Panels have also been specified for installation throughout the hotel bedrooms and communal areas to provide concealed and maintenance free access to the ceiling shafts.

Due to the significant size of the ceiling access panels, which span up to 1100mm x 1800mm, Profab Access developed a bespoke additional safety system that featured a one side lift out and one side swing/push latch mechanism. The innovative design assisted BDL Dry Lining’s team of engineers in stopping the heavy doors swinging from the ceiling, while also enabling the panel design to work within a reduced space.

BDL Dry Lining is one of the largest specialist dry lining contractors in the UK and has been an installer of Profab Access riser doors and access panels on high profile commercial and residential projects for a number of years.

Tony Grayson, Project Manager at BDL Dry Lining, said: “This is a standout development to be involved with and we knew from the very beginning that Profab Access would be our go to supplier for this project.

“Over the last two years we have worked closely with Access 360’s team of Specification Managers and Engineering experts to deliver and install the riser doors and ceiling access panels throughout the 41 storeys. The access solutions are extremely easy to install and offer the highest standards in performance, quality and compliance for unfaltering consistency across the entire site.”

The riser doors are also 35dB acoustic rated, smoke sealed and airtight to Part L. In the event of a fire, the doors will maintain their frame and integrity for up to two hours, limiting the spread of fire and transmission of radiant heat for this period of time. The doors’ intumescent smoke seals also enables occupants to safely exit the building, whilst subsequently minimising potential damage to other areas of the construction.

By specifying the CERTIFIRE bi-directionally fire tested 4000 Series Riser Doors, the development is actively future proofed as the comprehensive testing certification provides a complete and transparent audit trail of due diligence that evidences the products are not only fit for purpose, but meet the duty of care required to ensure legal compliance.

Mick Hill, Lead Technical Manager at Profab Access, said: “As One Bishopsgate Plaza is such a unique building, it required a bespoke approach that ensured the access solutions we provided were not only fit for purpose, but superseded expectations.

“That’s why every element of the ceiling and wall access products have been individually considered, from the additional safety systems on the ceiling access panels, to the Euro Cylinder locks on the riser doors to prevent unauthorised access. The result is a complementary suite of solutions that provide unobtrusive access, without compromising on aesthetics.”

Profab Access’ comprehensive portfolio of access panels and riser doors are manufactured in-house at its headquarters in Atherstone and are supplied with impressive lead times throughout the UK. The products are supported by a wide range of BIM Level 2 and CAD files to aid the specification process and streamline the initial design stages.

Manufactured in accordance with ISO 9001, the 4000 Series Riser Doors and 7000 Series Ceiling Access Panels can be specified and installed in a range of configurations to meet each project’s specific measurements and requirements.

For further information on Profab Access and its range of riser doors, access panels, and steel doors, call +44(0)1827 719051 or visit www.profabaccess.com.

View Access 360's profile:

Crittall on the curriculum

Story

School and college authorities that need to improve the learning environment while enhancing their green credentials are turning to leading steel window manufacturer Crittall which has a suite of products to upgrade both external appearance and interior comfort.

The education sector has a massive investment in its built environment and, despite the temporary dislocation caused by the pandemic, remains eager to find ways to keep control of costs and bear down on excessive energy consumption as things eventually return of normal.

Crittall offers a range of windows that are finding favour with the most prestigious educational establishments, in some cases presenting a fresh, modern aesthetic, in others replacing worn out fenestration that replicates a heritage appearance while greatly enhancing thermal performance.

And moving to the inside of the building a range of internal screens can provide for a lighter, more welcoming interior with no compromise to acoustic, security and safety requirements.

Popular among school and college authorities is the highly successful Corporate W20 window with its slender but strong frames. For example, a programme of maintenance and energy efficiency improvement at the University of Sussex has involved the installation of W20 profiles throughout the Falmer campus, outside Brighton. The windows have been installed in four buildings across the site, replacing the Crittall originals dating from when the university was first created in the early 1960s. Two of the refurbished buildings were Grade 2* listed.

At Corpus Christi College, Cambridge, Corporate W20 windows were installed in a modernist, concrete-framed accommodation block, also Grade 2 listed. Meanwhile at the Levine Building at Trinity College, Oxford, the T60 advanced thermally-broken windows have been specified. This profile can mount double or triple glazing to deal with harsher weather conditions and is suited to either new-build or replacement in listed buildings or conservation areas to meet the exacting requirements of local planning authorities.

Greatly improved thermal performance but with a like-for-like appearance was demanded by planners in the north London borough of Enfield when a special school, Durants, decided to expand into an existing classroom block on a nearby site. Original 1950s single glazed steel windows were replaced with new double-glazed thermally-broken steel windows that exactly mimicked the appearance of the originals. Overall U value for the completed project is 1.8 W/m2K based on a glass centre pane value of 1.0 W/m2K. The double glazing incorporates toughened low E glass and an 18mm argon filled cavity.

Alternatively, the MW40 profile can be specified where superior air, wind or water resistance and greater sound attenuation are required. Offering the same high quality appearance as the W20 range the MW40 profile can accept glass up to twice the thickness as its stable mate. Either double, or even triple, glazing up to 32mm thick can be installed with a consequent higher level of thermal or sound insulation.

Yet this is achieved while retaining the same slender steel profile for which Crittall products are renowned thereby ensuring maximum light ingress.

In addition to exterior steel windows and doors with their slim profiles Crittall’s InnerVision glazed interior screens ensure a seamless transfer of increased levels of natural daylight throughout the building reaching even the most remote working areas.

Solid partitions dividing workspaces can be replaced with glass and the performance of glazed interior screens can be further tailored to fine-tune

levels of acoustic insulation, light transmission, thermal insulation and natural ventilation control to suit individual client’s requirements.

Crittall’s InnerVision range of glazed internal fixed screens and doors can now be specified for fire rated applications. The steel framed system is compliant with BS476 Part 22 providing 30 minutes (FD30) integrity fire resistance. The profiles match the Corporate W20 exterior window range in appearance and can be supplied as fixed screens, with single or double leaf-hinged doors.

‘Steel windows will out-perform other window materials in terms of longevity – evidenced by many that can still be seen in iconic buildings today’ states Russell Ager, Crittall managing director.

‘The low life cycle cost compared with other window materials, combined with the robustness and material selection to further reduce the burden of maintenance, properly maintained steel windows are expected to last the lifetime of a building’

He continued ‘maintenance is very straightforward with just periodic inspection and cleaning required’

Contact the Crittall commercial specification team on 01376 530800 for further details or visit www.crittall-windows.co.uk.