All posts by admin

Low surface temperature radiator series sees new additions

Story

Low surface temperature radiators – known as LSTs – are increasingly being specified for buildings used by vulnerable people where safe heat is required – for either the young or the elderly. The leading supplier of LST radiators in the UK is Stelrad and the company has recently released two new additions to its already extensive range by adding an LST Standard Deco and LST iPlus Deco design. They both feature its popular Deco horizontal lined fascia to the casings.

Low surface temperature radiators – known as LSTs – are increasingly being specified for buildings used by vulnerable people where safe heat is required – for either the young or the elderly. The leading supplier of LST radiators in the UK is Stelrad and the company has recently released two new additions to its already extensive range by adding an LST Standard Deco and LST iPlus Deco design. They both feature its popular Deco horizontal lined fascia to the casings.

LSTs are clearly the safe solution in hospitals, care and nursing homes, doctors and dentists’ surgeries and in universities, colleges, schools and nurseries.

The addition of the Deco fascias is a response to demand from customers to have a ‘designer look’ version of these popular but functional radiators and Stelrad has been happy to respond to this.

LSTs comply with the strict requirements of the NHS Guidance Note for ‘Safe hot water and surface temperature’ and can be installed in commercial and public buildings with total public safety assured. The surface temperature of these LSTs will never exceed 43°C.

For more details, head for www.stelrad.com.

View Stelrad's profile:

Take a Closer Look at Small Circulators

Story

It’s thought that there are still many millions of old, uncontrolled small circulators operating in heating systems across the UK, and they are using far more energy than they need to.

Especially now that leading pump manufacturer Wilo now offers the new generation of the Wilo-Yonos PICO series small circulators to the UK market. There’s a range of new features that have been added to this popular circulator, targeted primarily at residential homes and properties, for both heating systems and air conditioning equipment.

With this new version, Wilo has succeeded in not only upgrading one of the most established products in the market, but also to an extent, it has been able to reinvent it thanks to new functions built in to it and its ease of use.

With this new version, Wilo has succeeded in not only upgrading one of the most established products in the market, but also to an extent, it has been able to reinvent it thanks to new functions built in to it and its ease of use.

Together with these new functions, the compactness of Wilo-Yonos PICO has been dramatically improved to make it even easier to install and make maintenance far easier for the installer.

For more information on the Yonos PICO and the other small pumps in the energy efficient Wilo family of circulators, head for www.wilo.co.uk.

View Wilo's profile:

Crabtree: 1919 to 2019 and Beyond

Story

One hundred years ago John Ashworth Crabtree designed and patented a quick make and quick break switch. This innovation, which safely managed electric arcs that can occur in switching devices, was the beginning of the philosophy that became the culture of electrical safety for Crabtree.

One hundred years later and Crabtree remain at the forefront of electrical safety, this time with digital technology in Arc Fault Detection Devices. Crabtree AFDDs automatically detect and disconnect arc faults and prevent fires occurring in electrical cables and final circuits, providing higher levels of safety for homes and workplaces.

A lot can change in 100 years. Technology develops, new challenges emerge, solutions are found. But despite it all, the earth continues to turn, and those with a passion continue to design and innovate.

For a business that has weathered the storms of time, changed ownership, evolved its working methods and undoubtedly over 100 years, engaged many staff; one thing hasn’t changed, and that is the drive for new product development – a vital ingredient in the success of the brand.

We’re now on the 18th Edition of the Wiring Regulations, but back when the 12th Edition of the wiring regulations was just being published in 1950, Crabtree had been operating for over 30 years. It had launched during that time a number of innovations, including one still used today – British standard 13A twin sockets. Now a staple in homes and businesses across the UK, British standard 13A twin sockets first introduced by Crabtree in 1947.

In 1956, Crabtree introduced its first earth leakage circuit breaker, the voltage operated E.60 range. Earth leakage circuit breakers (or RCDs as we now know them) are standard products these days, but they were new in the 1950s when Crabtree developed this technology for devices that protect people from risks of electric shock. Fast forward 60-odd years to the very latest earth leakage devices and you will find innovative “A Class” Miniature RCBOs that include two-pole switching as standard for even higher levels of  personal protection.

personal protection.

Mike Cash, Group Marketing & Channel Manager at Electrium commented: “When Crabtree launched, we had a motto: That which is built soundly endures well. It was inscribed onto the company plaque and rightly so. Crabtree was built soundly enough to provide 100 years of electrical safety for our customers. And with a 100-year solid foundation what else can we do in the years to come?”

For more information go to www.electrium.co.uk/crabtree

View Crabtree's profile:

Condair Humidifiers At The National Army Museum

Story

Condair has recently supplied and installed three Condair RS resistive steam humidifiers to maintain the humidity around the exhibits and archives at the National Army Museum in Chelsea, London.

Condair has recently supplied and installed three Condair RS resistive steam humidifiers to maintain the humidity around the exhibits and archives at the National Army Museum in Chelsea, London.

Optimum environmental conditions are required to ensure the perfect preservation of military artefacts that are made of a wide range of materials, some of which date back to the English Civil War.

Mike O’Connor, Deputy Director at the National Army Museum, commented, “Precise climate control in our galleries and stored collections, across both temperature and humidity, plays an important role in preserving the nation’s military heritage. Our collections include an array of exhibits, from the cloak Wellington wore at Waterloo and Lawrence of Arabia’s dagger to modern day grenade launchers and drones. Metals, textiles, wooden objects and paintings can all be affected by high or low humidity, so a stable environment ensures longevity and avoids costly restoration work.”

The three Condair humidification systems were installed in weatherproof enclosures on the roof of the museum as part of its recent £24M refurbishment project. As well as resisting the London weather, the Condair enclosures incorporate a heater and fan unit to ensure the internal conditions remain within the humidifier’s recommended operating range. So, just as the humidifiers help the museum preserve its exhibits, likewise the enclosures do the same job for the humidifiers.

The Condair RS resistive steam humidifier is the ideal choice for heritage applications due to its responsive control and innovative scale management system. It can operate on mains water, as it is at the National Army Museum, and provide ±3%RH control, or on RO water and offer a close ±1%RH control. A humidifier that gives rapid response and close humidity control is important for museums that can be empty one minute and full of tourists in from the rain the next.

A patented scale management system on the Condair RS allows in-house maintenance teams to undertake routine scale removal, safely and quickly, without even needing to open the humidifier’s main cabinet. A scale collector tank is located under the boiling chamber, into which scale falls during operation. Scale removal is a simple process of draining the unit with the push of a button, disconnecting the cooled collector tank and emptying it.

The National Army Museum is the leading authority on the British Army and its impact on society past and present. It displays thousands of pieces across five themed galleries with a special temporary exhibition gallery, event space, a café and children’s area, Play Base. Admission is free to the permanent galleries and the Museum is open to the public between 10am and 5.30pm, daily.

The Condair Group is the world’s leading specialist in humidity control and evaporative cooling, with energy efficient, hygienic and innovative technologies for commercial, industrial and heritage applications. Condair is represented in the UK by Condair plc, which offers system design, manufacture, supply, installation, commissioning, maintenance and spares. You can find out more by visiting the company’s website at www.condair.co.uk.

View Condair's profile:

A sound specification for Bona Craft Oil 2K

Story

Bona Craft Oil 2K has been specified for the restoration of the Beech floor in the world’s largest purpose-built recording studio. The work was undertaken by Bona Certified Contractors, CMT Wood Flooring of Birmingham, contracted to commercial fit out specialists, Prestige Interiors.

Bona Craft Oil 2K has been specified for the restoration of the Beech floor in the world’s largest purpose-built recording studio. The work was undertaken by Bona Certified Contractors, CMT Wood Flooring of Birmingham, contracted to commercial fit out specialists, Prestige Interiors.

The London based studio is in constant use by orchestras and choruses. It was therefore essential that a highly durable finish was applied, that would not only protect the surface from the high levels of traffic but would also dry quickly to minimise downtime in this very busy space. CMT flooring initially recommended the use of Bona Traffic HD, the toughest waterborne lacquer manufactured by Bona, and which dries so quickly that the floor can be put back into full use in just 12 hours.

However, the studio team were concerned that using a lacquer finish on the floor, which had been previously oiled, might change its acoustic properties. Consequently, the specification was changed to highly durable Bona Craft Oil 2K, a penetrating, two component oil with an equally impressive drying time of just eight hours for the ‘Neutral’, uncoloured version – meaning the studio could be put back into full use the day after treatment.

To retain a sense of history in the space, it was also decided not to use a darker oil on the lighter coloured blocks (that were laid after a stage was removed from one end of the studio) so they matched the original darker coloured floor. However, had the studio team wanted to create a uniformly coloured floor, this could have easily been achieved by treating the lighter blocks with one of the darker coloured versions of Craft Oil 2K.

Before applying the oil, the CMT team repaired several loose and damaged blocks and then sanded the floor and filled all gaps with filler mixed with dust from the final sanding pass. One coat of Bona Craft Oil 2K was then applied with a Bona FlexiSand buffing machine – using a red pad – an efficient way of applying oil to a floor this size and which ensured the surface layer of timber was uniformly saturated.

Bona Craft Oil 2K is a unique formula based on modified plant-based oil and has a very low VOC content of less than 4%. It’s the perfect treatment for a wide variety of wood species including tricky ones such as cherry and walnut, and it produces a strong water and stain resistant surface that is ready for use in 8 or 12 hours (depending if neutral or coloured versions are used). In situations where supreme surface durability is required, Bona Craft Oil 2K can be overcoated with any version of Bona Traffic lacquer.

Alec Stacey, Technical Manager at Bona Limited, said, “It was unusual for us to have to consider the acoustic properties of one of our finishes before creating this specification, but understandably this was of paramount importance for the studio team. Another beneficial property of a ‘traditional’ oil finish, is the ease with which local repairs can be made, usually without sanding. Any areas that become worn or discoloured can be corrected by simply buffing more oil into these areas and removing the excess.

To ensure the floor remains looking good and performing well, the recommended maintenance regime includes regular cleaning with Bona Soap, occasional treatments with Bona Care Oil and yearly inspections to ensure the floor is professionally refinished with oil when required.

View Bona's profile:

Busy March for Saniflo at Future Build in London and ISH in Frankfurt

Story

March is set to be a busy month for Saniflo with two important exhibitions. From 5-7 March, catch the experts from Saniflo at Future Build, Excel, London on stand B165. At Future Build, Saniflo will also deliver a talk in the ‘Let’s Talk Specification’ seminar programme. From 11-15 March 2018, visitors to ISH in Frankfurt, Germany, will find Saniflo in Hall 9.0 on stand E62 with the complete range of macerators, pumps & lifting stations; and, in Hall 3.0 on stand C93 with the Kinedo range of shower solutions and some related products, including the new Sanifloor+.

March is set to be a busy month for Saniflo with two important exhibitions. From 5-7 March, catch the experts from Saniflo at Future Build, Excel, London on stand B165. At Future Build, Saniflo will also deliver a talk in the ‘Let’s Talk Specification’ seminar programme. From 11-15 March 2018, visitors to ISH in Frankfurt, Germany, will find Saniflo in Hall 9.0 on stand E62 with the complete range of macerators, pumps & lifting stations; and, in Hall 3.0 on stand C93 with the Kinedo range of shower solutions and some related products, including the new Sanifloor+.

Saniflo – inventors of the macerator with more than 60 years’ experience and the number one in the UK macerator market – is no stranger to exhibitions and consistently exhibit at a variety of industry events across the UK and Europe.

Saniflo UK Head of Marketing and Product Development, Ann Boardman, says: “We are looking forward to welcoming visitors to Future Build and ISH where they will find an extensive range of Saniflo products on display.

“Future Build is a new exhibition for us and an ideal opportunity to connect with our UK customers. This year we are focusing on displaying our range of Kinedo shower cubicles, enclosures and trays, and we will also deliver a talk in the ‘Let’s Talk Specification’ seminar programme.

“ISH is always a valuable event for us, hence why we choose to have a strong presence there. It allows us to have many products on show at one time to reach a high volume of people in a short period of time. It’s important to demonstrate how we innovate to remain ahead of market demand. Saniflo literally has an easy solution for every situation and ISH offers a great opportunity to show that. People can experience for themselves our hassle-free, plug and play range designed to be the best on the market featuring ease of installation and maintenance with new and improved styling and vibration reduction.”

View Saniflo's profile:

Three ways to wire with addition of lever and push-button terminal blocks

Story

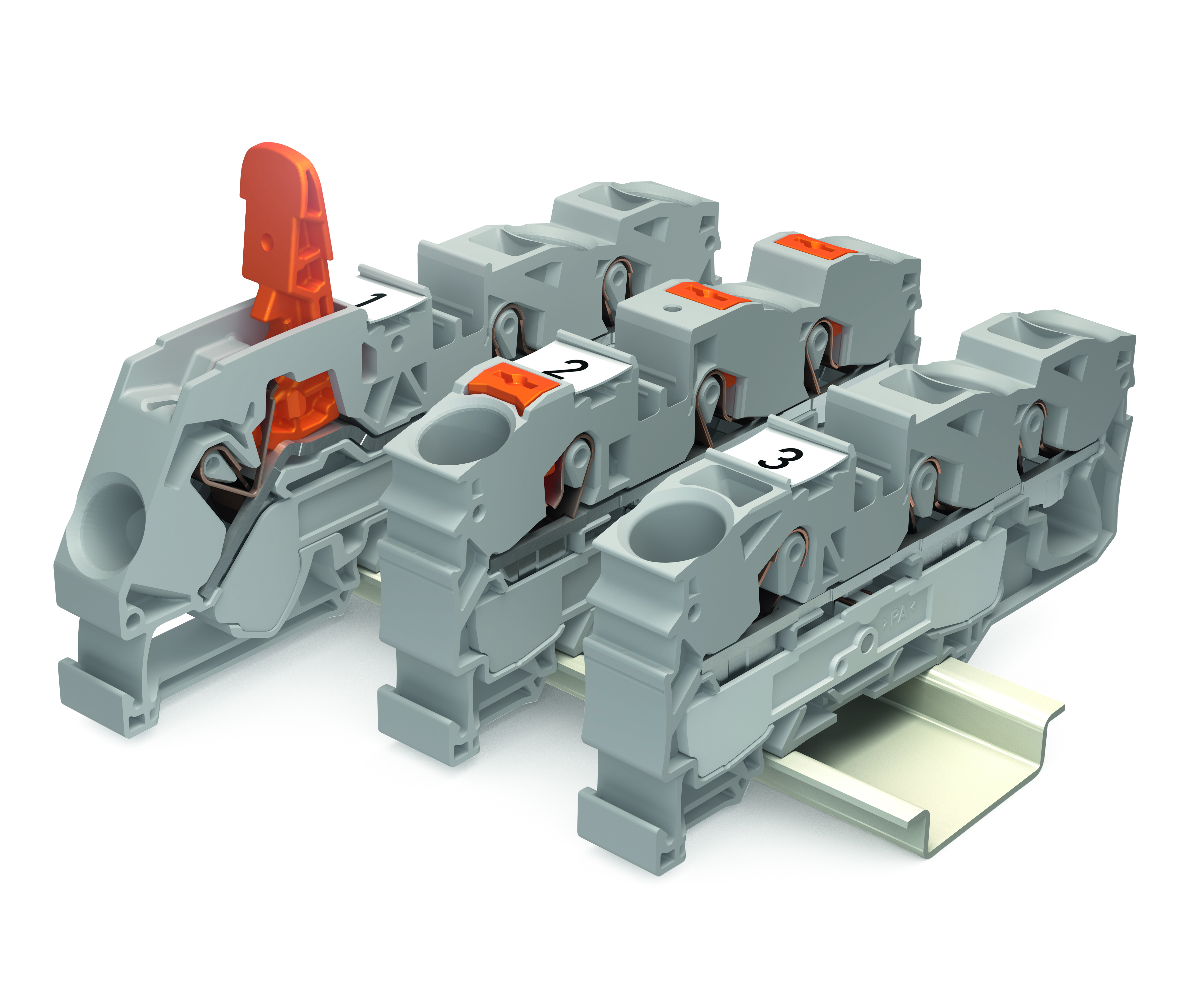

Interconnection specialist WAGO introduces push-button and lever-actuated variants to its TOPJOB S® terminal block family. Integrators can now choose between push-button, lever and push-in connection methods for additional flexibility on DIN rail installations.

The lever-actuated variant, a world first from WAGO, is equipped with a lever on the field side, and a push-button or operating tool-actuated connection on the factory side. The clamping point on the field side is opened and closed by hand using the lever, allowing installers to tell at a glance which wires in an assembly are terminated. The lever can also be left open, freeing both hands to connect difficult-to-bend conductors with large cross sections.

Versions are available for nominal cross-sections of 2.5 mm², 6 mm² and 16 mm², and in 2- or 3-conductor configurations.

The clamping point of the push-button mechanism is opened with any screwdriver or similar operating tool. Feed-through terminal blocks with push-buttons are available for wire with a cross-section between 0.14 to 25 mm². The push-button terminal block is available in 2-, 3- or 4-conductor variants, which allow push-in connection of solid, seven strand and ferruled conductors.

Both the push button and lever actuators are orange in colour, making them clearly visible for easy identification.

All TOPJOB S rail mounted terminal blocks feature Push-In CAGE CLAMP® spring pressure connection, which is 50 percent quicker to wire compared to screws, and immune to loosening over time. The terminal blocks are also resistant to vibration and overcurrent, and free from maintenance, eliminating the need to periodically check and tighten loose connections while improving overall reliability.

View Wago's profile:

New Outdoor Steam Humidifiers from Condair

Story

Leading humidification specialist, Condair, has extended its range of electric steam humidifiers to include new IP55 rated models suitable for outdoor installation. The robust enclosures on the Condair RS resistive steam and Condair EL electrode boiler steam humidifiers enable the units to be located on rooftops and exposed to the elements.

Rather than simply installing the standard humidifiers inside a protective housing on a rooftop, the new outdoor humidifiers from Condair have purpose-built IP55-rated casings. This means they take up much less room on a rooftop and are easier to install. Condair’s new outdoor humidifiers are the most compact in the industry with the smallest footprint and incorporate lifting handles to make on-site transportation easier.

The enclosures incorporate a thermostat-controlled heater and fan unit to maintain the internal temperature at an optimum level with outside ambient conditions ranging from -20° to 40°C. An anti-freeze valve will ensure the humidifier completely drains should the unit experience temperatures of less than 6°C during periods of in-operation.

The new Condair outdoor humidifiers can be wall-mounted, allowing them to be attached to an AHU, or free-standing. Lockable doors are removable for easy access and optional internal lighting improves visibility for servicing and maintenance.

Alongside these new enhanced “outdoor” features, the Condair RS and Condair EL steam humidifiers inside the robust outer casing still offer all the innovative features that make these resistive and electrode humidifiers market-leaders. The latest touch-screen control panel gives intuitive control over operation and reporting, and a USB connection allows software to be updated and historic operational information downloaded into Excel.

The Condair RS resistive steam humidifier has an innovative scale-management system that sees limescale detach from the heating elements and fall into a scale-collector tank. This can be occasionally emptied to remove scale from the system without the need for major maintenance downtime. The Condair EL electrode boiler humidifier has advanced water quality management that precisely maintains the mineral content of the boiling cylinder. This avoids the need for excessive flushing of hot water to drain and minimises limescale formation.

The Condair Group is the world’s leading specialist in humidification and evaporative cooling, with energy efficient, hygienic and innovative technologies for commercial, industrial and heritage applications. Condair is represented in the UK by Condair plc, which offers system design, manufacture, supply, installation, commissioning, maintenance and spares. You can find out more by visiting the company’s website at www.condair.co.uk.

View Condair's profile:

Quiet Mark Award For Armourcoat Acoustic

Story

Armourcoat’s new Acoustic Plaster System has been granted the Quiet Mark Award – the international mark of approval from the Noise Abatement Society Charitable Foundation.

Quiet Mark is the international award programme and system of support for brands and consumers. Through its pioneering acoustic tests, the organisation awards its distinctive Purple Q Mark to products and services that show excellence in low-noise and high-performance.

Designed to optimize the acoustics of interior spaces, the Armourcoat Acoustic plaster system offers a clean and smooth mineral surface that can be applied seamlessly over large expanses to both flat and curved surfaces. Comprising of a special mineral wool composite panel that is bonded onto the substrate and finished with a seamless layer, the system presents an elegant marble-based plaster finish while allowing sound energy to pass through the surface.

The Armourcoat system includes a high percentage of pre and post-consumer recycled material, zero VOCs, is class ‘0’ fire-rated, and achieves a class ‘A’ Noise Reduction Coefficient rating for the 50mm system.

Poppy Szkiler, Founder and Managing Director, Quiet Mark, comments: “We welcome Armourcoat to the growing family of global organisations that are prioritising investment in acoustic research to create quieter solutions, as recognised by the Quiet Mark award. Armourcoat’s innovative acoustic plaster system performs to the highest building standards and incorporates special wool composite. This delivers excellent noise reduction properties and minimises the unnecessary intrusion of unwanted sound into our buildings, allowing the creation of a peaceful and supportive aural environment in our homes and places of work.”

View Armourcoat's profile:

Fahim Karim – new Specification Sales Manager for Saniflo

Story

Saniflo is pleased to announce the appointment of Fahim Karim as Specification Sales Manager for the South. This new role will focus predominantly on the Kinedo range of cubicles, enclosure and trays.

Having graduated from Brunel University in Uxbridge with Masters in Molecular Medicine and Cancer Research, Fahim was subsequently attracted to a career in sales and has since spent over 7 years in Specifications.

With experience in selling furniture, bespoke flooring and windows for new build and refurbishment projects he has excellent experience in dealing with architects, designers, developers, contractors and house builders; precisely the professional contacts required in this newly created role.

Outside work Fahim is an avid traveller and has explored the Middle East, Eastern Europe and America in the last few years. He is also a football and basketball fan.