All posts by admin

HIGH EFFICIENCY SMALL CIRCULATORS – Is ErP Legislation working?

Story

European legislation has its friends and its enemies as we have discovered, having survived the rigours of a recent General Election. Whatever the outcome of the promised referendum on EU membership here in the UK, we have to get on with abiding by European Directives for now. With many of the day to day products in use in the heating and plumbing sector being manufactured by European companies, it seems highly likely that with much of the legislation already in place and being acted upon, it would stay whatever the outcome. In the EU, or out, we clearly as a nation, need to reduce carbon emissions and continue to clean up our act on the environmental stage.

European legislation has its friends and its enemies as we have discovered, having survived the rigours of a recent General Election. Whatever the outcome of the promised referendum on EU membership here in the UK, we have to get on with abiding by European Directives for now. With many of the day to day products in use in the heating and plumbing sector being manufactured by European companies, it seems highly likely that with much of the legislation already in place and being acted upon, it would stay whatever the outcome. In the EU, or out, we clearly as a nation, need to reduce carbon emissions and continue to clean up our act on the environmental stage.

There is still a lack of realisation in some circles, of the amount of energy that is used day to day by pumps as a proportion of energy use in the average home. And every home pretty much, has one. Once understood, it’s easy to see why it was a prime area for attention when looking for ways of reducing energy use and reducing carbon emissions. In today’s vernacular, it was something of a ‘no brainer’.

Small circulating pumps are a key component of all wet heating systems in the UK – whether traditional boiler driven systems or new renewable systems. They perform as standalone pumps or as integrated pumps in combi and system boilers and they keep the water circulating in underfloor heating systems too. They are responsible for a much higher percentage of overall household electricity usage than many still realise which is why old uncontrolled pumps were targeted by European legislation as a key way of reducing energy usage in the home, reducing energy bills and reducing emissions. They offered a real way of making strides towards meeting the ambitious environmental targets set by the UK Government and European legislators.

Small circulating pumps are a key component of all wet heating systems in the UK – whether traditional boiler driven systems or new renewable systems. They perform as standalone pumps or as integrated pumps in combi and system boilers and they keep the water circulating in underfloor heating systems too. They are responsible for a much higher percentage of overall household electricity usage than many still realise which is why old uncontrolled pumps were targeted by European legislation as a key way of reducing energy usage in the home, reducing energy bills and reducing emissions. They offered a real way of making strides towards meeting the ambitious environmental targets set by the UK Government and European legislators.

Before January 2013, small circulating pump selection was often made on price. Although some installers had loyalty to a brand, in many people’s eyes, a pump was a pump was a pump. If it did the job, it did the job. There were a few high efficiency pumps on the shelves before the end of 2012, but at a far higher price than the standard efficiency ones. Until legislation said that you had to install them, despite some installers deciding that a high efficiency pump was what the customer deserved as part of an energy efficient heating system, from sales figures alone, it was clear that many were voting with their wallets.

From January 2013 high efficiency pumps were demanded by EU Legislation – the much vaunted ErP Legislation – and whilst there was initially some resistance to comply, as 2013 unfolded and availability of anything other than high efficiency options declined, installers began to buy and install and specifiers began to specify the high efficiency options. Now, just a few months down the line, high efficiency pumps have been accepted and are being installed in their thousands across the UK, with for example, some social housing landlords undertaking major pump replacement programmes, to help reduce their tenants’ electricity bills.

From January 2013 high efficiency pumps were demanded by EU Legislation – the much vaunted ErP Legislation – and whilst there was initially some resistance to comply, as 2013 unfolded and availability of anything other than high efficiency options declined, installers began to buy and install and specifiers began to specify the high efficiency options. Now, just a few months down the line, high efficiency pumps have been accepted and are being installed in their thousands across the UK, with for example, some social housing landlords undertaking major pump replacement programmes, to help reduce their tenants’ electricity bills.

Despite this embracing of the new legislation and availability of the new ErP compliant circulating pumps, the fact remains that there are still many millions of old, uncontrolled small circulators operating in heating systems across the UK. So there is still huge potential to further reduce energy use and energy bills in the months and years ahead. Wilo and other pump manufacturers have begun to see their high efficiency models begin to sell well. Helped by the legislation, there was little choice but to utilise the new high efficiency models.

Although the concept of lifecycle costs was not new in January 2013 when ErP came into force, it was a concept that had largely been associated with commercial projects rather than domestic ones. But suddenly it became more important and the additional costs that inevitably follow the development of exciting new technology – in this case the vastly improved electronics and the arrival of electronically commutated motors (ECMs) for small circulating pumps – were justified by the lower life cycle costs of the new high efficiency, more expensive pumps and the huge savings possible over a ten or fifteen year operational life time. These could pay for the increased capital cost of the pump at the outset, many times over.

Wilo has just announced it is celebrating the sale of 28 million small circulators in the past ten years. In addition the company recently celebrated the selection of its small circulators as the pumps in the new combi boilers launched by two major boiler manufacturers here in the UK. Wilo’s high efficiency small pumps – in particular the Wilo-Yonos PICO – have made a huge impact in the UK heating and air conditioning sector over the past two and a half years, since the arrival of the ErP legislation in January of 2013.

Wilo’s series of glandless pumps – Wilo-Yonos PICO, Wilo-Stratos PICO and Wilo-Stratos – are seeing increasing popularity across the board. They are relevant for nearly all applications for heating, air-conditioning and cooling in the building services area – from the family home to a small commercial or industrial building.

Sadly, as always, some people will try to circumnavigate new legislation and ignore the drivers for environmentally friendly products. There has been genuine concern in the pump industry about the on-going availability of non-ErP compliant pumps, and the mislabelling of some pumps being imported into the UK and European markets since January 2013. European manufacturers are concerned that these pumps, although cosmetically looking like the new high efficiency models, in some cases, do not meet the requirements of the ErP regulations. Wilo, along with fellow members of the British Pump Manufacturers Association, continues to monitor this situation and report breaches of the regulations to the relevant authorities.

In general terms, the arrival of the EU ErP Directive has clearly begun to make significant inroads in the energy consumption figures, and as a result the emissions figures. There’s a long way still to go to hit the targets being demanded. But the age of the energy efficient pump is very much here.

To find out more about Wilo’s highly convenient, reliable family of high efficiency, ErP compliant small circulating pumps, just click on to www.wilo.co.uk.

View Wilo's profile:

Timbmet builds for the future

Story

The Timbmet Group has had a second consecutive year of improving both their gross and net profitability and stabilising revenues. To build on the secure business platform now in place, Timbmet is planning for further growth.

The Timbmet Group has had a second consecutive year of improving both their gross and net profitability and stabilising revenues. To build on the secure business platform now in place, Timbmet is planning for further growth.

Chairman, Simon Fineman, comments: “The Group is pleased to report an operating profit before exceptional costs of £2.126 million, compared with £1.782 million last year. Given the actions taken by the group in recent years and the future plans, both supported by an easing of economic pressures, the board are confident that the business will continue to grow and to trade profitably in the current financial year.”

The decisive action in the first half of 2013 to restructure the management team and certain operational elements of the business has been reflected in the results for the last two years.

UK Managing Director, Nigel Cox, reports: “The underlying trend for the UK business was an increase of 7.1%, with our overseas business showing a strong growth of 31.1%. Overall, group sales fell by 1.0%, but this includes the discontinuation of low margin direct business to a major DIY chain. As a result, the gross profit percentage increased by 1.7 percentage points.

“Our intention now is to invest further by enhancing our stock range and increasing the number of front line sales staff so that customers get the advice and support that they need. Operationally we’re investing in our business infrastructure, expanding our warehouse capabilities and upgrading our fleet to enable us to effectively process the orders and, ultimately, deliver the product.”

Chief Executive, Paul Rivers, notes: “It is very pleasing to see the efforts of the last two years reflected in the group’s return to stability and profitability. We are continuing to work on forward planning to continue increasing the rate of sales growth and profitability of the business. This will in turn allow for greater re-investment for the future.”

Paul continues, “We want to be a business that customers want to trade with, because our service is better, our products are right and because our staff understand what the customer needs.”

Timbmet has also continued to review their closed final salary pension scheme. This year an additional non-cash exceptional cost of £1.0 million was recognised to correctly equalise retirement ages under the scheme. The 2014 triennial valuation of the scheme has been completed, and a new and longer deficit reduction payment plan will apply from July 2015. This will reduce the group’s contributions to the scheme for the next three years.

View Timbmet's profile:

Aperam stainless steel shingles for Borders Visitor Centre

Story

UGINOX® TOP from Aperam, has been installed as shingles by Longworth Metal Roofing, to provide a permanent, durable matt façade on the Galashiels Transport Interchange. As the tourism entry point to the Scottish Borders it was designed as a ‘statement building’ with the facade a key element of the design as it looks out onto the Borders Railway. The Interchange provides an improved connection between the inner relief road, railway and bus station as well as excellent visitor and passenger facilities.

UGINOX® TOP from Aperam, has been installed as shingles by Longworth Metal Roofing, to provide a permanent, durable matt façade on the Galashiels Transport Interchange. As the tourism entry point to the Scottish Borders it was designed as a ‘statement building’ with the facade a key element of the design as it looks out onto the Borders Railway. The Interchange provides an improved connection between the inner relief road, railway and bus station as well as excellent visitor and passenger facilities.

In addition to being specified for its lasting appearance and sustainability, stainless steel was chosen in preference to aluminium as the installed cost was found to be considerably less. UGINOX TOP is a double-sided surface texture and has been designed for use in traditional or contemporary designs in either rural or urban environments.

Considered to be the most sustainable of the hard metals, stainless steel does not oxidise or weather in any way, causes no problems with run off, is easy to work and has very low maintenance requirements.

View Aperam's profile:

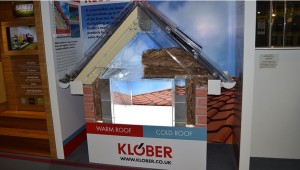

Klober airtightness accessories at the Building Centre

Story

For those designing energy-efficient buildings, roofing specialist Klober now has a permanent exhibit at the Building Centre. Klober has pioneered the development of tapes, sealants, sealing collars and vapour control layers to seal the roof space, ceilings and tile penetrations. The company also manufactures high performance air-open and vapour permeable underlays for all roof types and pitch in order to provide balanced ventilation and airtightness. As with all exhibits at the Building Centre, brochures are available on site or via Specifinder – http://tinyurl.com/p4mjgmz. A roofing airtightness CPD presentation can also be booked by calling Ann Leeson on 01332 813060.

For those designing energy-efficient buildings, roofing specialist Klober now has a permanent exhibit at the Building Centre. Klober has pioneered the development of tapes, sealants, sealing collars and vapour control layers to seal the roof space, ceilings and tile penetrations. The company also manufactures high performance air-open and vapour permeable underlays for all roof types and pitch in order to provide balanced ventilation and airtightness. As with all exhibits at the Building Centre, brochures are available on site or via Specifinder – http://tinyurl.com/p4mjgmz. A roofing airtightness CPD presentation can also be booked by calling Ann Leeson on 01332 813060.

View Klober's profile:

Blackpool Pleasure from Bradite

Story

One of the most famous amusement parks in the UK is being kept in  tip top condition thanks to products from the Bradite paint and primer range. Blackpool Pleasure Beach amusement park is located along the Fylde coast in Blackpool, Lancashire, and with millions of visitors a year, it is essential that the most visited tourist attraction in the United Kingdom is maintained on a rolling basis.

tip top condition thanks to products from the Bradite paint and primer range. Blackpool Pleasure Beach amusement park is located along the Fylde coast in Blackpool, Lancashire, and with millions of visitors a year, it is essential that the most visited tourist attraction in the United Kingdom is maintained on a rolling basis.

Keeping the rides in pristine condition considering the elements of the environment is no mean feat: sea and salt spray from the adjacent coast are a highly corrosive combination but First Leisure Group, who manage the park, has found a perfect solution in the Bradite range of products, which has been the paint of choice for the park for many years.

As part of the park’s rolling maintenance programme, the rides are being spot primed with Bradite EP92 and then coated with two coats of PG77 polyurethane gloss finish. As well as protection, the products also had to supply the required aesthetic finish: for structures the size of the rides at the amusement park, it was vital that an overall glossy, long lasting colourful finish was attainable that would catch the eye and entice visitors.

Each ride had its own colour theme, but the Bradite PG772 gloss finish is available in a broad range of RAL colours to satisfy the requirements of the theme park. Both the primer and the gloss finish were specified for their ease of use and longevity. The Bradite EP92 two pack polyamide adduct cured primer is designed for steel substrates, containing a high level of zinc phosphate anticorrosive pigment. It provides a tough hard wearing film, which is flexible and abrasion resistant. The primer was followed by application of the PG772 two pack polyurethane highbuild acrylic high gloss finish with excellent colour retention and weathering resistance. Surface dry in one hour, this is the perfect choice for the team of decorators at the Blackpool pleasure beach amusement park.

Painting the rides was not straightforward. The height and size of some of the rides meant that the decorating team has to abseil down the structures on ropes to complete the task, including the tallest ride in the UK, Pepsi Max Big One which towers 235 ft above sea level. Having a painting product range such as Bradite was an enormous benefit due to its ease of speed of application.

View Bradite's profile:

WARMING TO STELRAD IN ARK PUTNEY ACADEMY

Story

Whilst Stelrad radiators are often associated with residential installations, increasingly they are being specified for commercial and public buildings where the quality of their manufacture and consequent longevity as part of an energy efficient heating system make huge sense. One major area where Stelrad radiators are making their mark is in educational buildings – schools, colleges and universities across the UK, where they work equally well with traditional boiler driven heating systems or modern renewable systems, ground source and air source heat pumps in particular.

Whilst Stelrad radiators are often associated with residential installations, increasingly they are being specified for commercial and public buildings where the quality of their manufacture and consequent longevity as part of an energy efficient heating system make huge sense. One major area where Stelrad radiators are making their mark is in educational buildings – schools, colleges and universities across the UK, where they work equally well with traditional boiler driven heating systems or modern renewable systems, ground source and air source heat pumps in particular.

Putney Academy in south west London, is one of 31 academies owned and managed by ARK in the UK. The organisation took over the former Elliott School in 2012 and has set about improving the quality of the buildings and their surroundings in a big way, such that the main buildings have been totally refurbished with high quality, modern school facilities that will hugely benefit the pupils attending the academy. The work will be completed by the time staff and pupils return to school after the summer holidays.

Part of the major refurbishment work at the academy has inevitably seen the provision of a brand new heating system to provide comfort and warmth in the colder months of the year. Both the UK’s leading low surface temperature range – perfect for a building with young people, offering safe heat from radiators where the surface temperature of the attractive casing never exceeds 43 degrees C – and a smaller number of Stelrad Planar designer, flat fronted radiators along with a selection of traditional Classic Column radiators were specified for the project.

Skelly & Couch are the building environment and services engineers for the project. Director Mark Maidment says: “We wanted quality radiators to complement the other components of the heating system but in particular wanted to use LST radiators in areas of the academy where youngsters congregate to ensure maximum safety. Stelrad’s leading range of LST radiators are easy to install and offer the maximum protection to the end user – the casings actually cover the pipework as well as the radiator itself so there are no ‘hot’ areas that could cause any problems. In addition, it’s vital the radiators used in a school environment are built to be robust and able to withstand and resist vandalism and day to day wear and tear. With those manufactured by Stelrad, the casing is held by security fittings that are quick and easy to install. The security fittings have a unique seam fixing bracket system that prevents unauthorised access to the emitter inside the casing.”

Skelly & Couch are the building environment and services engineers for the project. Director Mark Maidment says: “We wanted quality radiators to complement the other components of the heating system but in particular wanted to use LST radiators in areas of the academy where youngsters congregate to ensure maximum safety. Stelrad’s leading range of LST radiators are easy to install and offer the maximum protection to the end user – the casings actually cover the pipework as well as the radiator itself so there are no ‘hot’ areas that could cause any problems. In addition, it’s vital the radiators used in a school environment are built to be robust and able to withstand and resist vandalism and day to day wear and tear. With those manufactured by Stelrad, the casing is held by security fittings that are quick and easy to install. The security fittings have a unique seam fixing bracket system that prevents unauthorised access to the emitter inside the casing.”

“We were delighted that our radiators were specified for this project,” says Stelrad’s Chris Harvey. “We’re seeing a huge increase in the use of our radiators in commercial and public buildings. The use of LST radiators in schools makes huge sense from the point of view that they provide safe heat whatever environment they are installed in and they are protected from tampering by the way they are fixed to the wall, ensuring that the heating systems on-going performance is not compromised.”

Full details of the wide range of radiators available from Stelrad can be found at www.stelrad.com.

Click on images to enlarge:

View Stelrad's profile:

Platon sealed system supplied for iconic fire brigade building conversion

Story

Triton has supplied 3,000 m2 of BBA certified Platon P8 cavity drain membrane to waterproof several basements at the iconic West Midlands Fire Brigade building at Lancaster Circus in Birmingham. The membrane forms part of a Type C drained waterproofing system (as defined in BS 8102 2009) to the area, which is being converted to residential accommodation for 463 students from Aston University.

Triton has supplied 3,000 m2 of BBA certified Platon P8 cavity drain membrane to waterproof several basements at the iconic West Midlands Fire Brigade building at Lancaster Circus in Birmingham. The membrane forms part of a Type C drained waterproofing system (as defined in BS 8102 2009) to the area, which is being converted to residential accommodation for 463 students from Aston University.

The system is being installed by Triton approved contractors, Protectahome, working for Watkin Jones Construction. Cavity drain membranes work by allowing any water ingress to continue to enter the building through the walls, but then controlling it and diverting it down the wall to a perimeter drainage conduit. In this project, the conduit diverts the water to one of 10 sumps, each housing a Triton Aqua Pump Pro Plus kit (each comprising mains powered and battery back up pumps).

Moisture had been penetrating into parts of the basement for several years through the wall/floor joint and various cracks in the original floor slab.  Although large floor areas have been excavated to allow for greater head height and replaced with new floor slabs, many of the original floors have been left in situ. As the Platon system allows moisture to enter the structure there is no hydrostatic pressure on existing floor slabs and no need to replace them.

Although large floor areas have been excavated to allow for greater head height and replaced with new floor slabs, many of the original floors have been left in situ. As the Platon system allows moisture to enter the structure there is no hydrostatic pressure on existing floor slabs and no need to replace them.

Triton’s technical team has worked closely with the architect, main contractor and specialist basement contractor from design inception through to overseeing installation and testing of the system.

View Triton Systems's profile:

Passivhaus Certified Office, Syston

Story

The new regional office for Interserve Construction Ltd in Syston, Leicestershire features some of the most advanced green building solutions to achieve a targeted 90% reduction in energy usage and costs compared with a traditional building.

The new regional office for Interserve Construction Ltd in Syston, Leicestershire features some of the most advanced green building solutions to achieve a targeted 90% reduction in energy usage and costs compared with a traditional building.

27 windows and four doors from the GENEO® system were installed in the £1.5m, 680m² Passivhaus certified office, the majority of which were across its south facing aspect to increase solar gain in winter and minimise the requirement to generate additional heat. The 86mm REHAU GENEO® window is manufactured using the 100% recyclable RAUFIPRO® fibre composite material.

The inherent strength of this material enables the six chambered REHAU GENEO® system to perform without any requirement for steel in standard sized windows, eliminating the thermal bridges which can occur in conventionally reinforced PVC-U and which result in energy being lost.

View Rehau's profile:

Download a FREE guide to Amendment 3 from Amtech

Story

Amendment 3 to BS 7671 (aka the 17th Edition Wiring regulations) is due to be published in January 2015 and will come into force in July 2015. To help electrical specifiers and installers get to grips with the new requirements, Amtech has published a handy guide to the five most significant changes.

Amendment 3 to BS 7671 (aka the 17th Edition Wiring regulations) is due to be published in January 2015 and will come into force in July 2015. To help electrical specifiers and installers get to grips with the new requirements, Amtech has published a handy guide to the five most significant changes.

Entitled ‘Five Shades of Yellow’, reflecting the distinctive yellow cover of Amendment 3, the Amtech publication takes each of these key changes in turn and provides an overview of the current situation and the significance of the forthcoming changes.

For example, it explains the significance of the new regulation numbering system, provides an overview of changes to requirements for protection against electric shock and explores the introduction of a new minimum voltage factor when calculating maximum fault loop impedance values for protective devices.

This invaluable reference document also flags up inclusion of characteristic curves for 2A and 4A rated protective devices and highlights an important change to the model inspection, testing certificates and reports.

Five Shades of Yellow can be downloaded at www.amtech.co.uk/five-shades. Its content is currently based on the proposed changes in Amendment 3 and will be updated should these change at the time of publication.

View Trimble MEP's profile:

Crittall’s stylish windows solution

Story

A prestigious headquarters building has been created within the stylish Harley Street Conservation Area in central London with the help of Crittall Corporate W20 windows both inside and out.

A prestigious headquarters building has been created within the stylish Harley Street Conservation Area in central London with the help of Crittall Corporate W20 windows both inside and out.

No. 116 Marylebone Lane, a four-storey 1930s building in the W1 area north of Wigmore Street, is owned by the Howard de Walden Estate and was previously in use as a Cordon Bleu cookery school.

Architects Morrow+Lorraine, who have particular expertise in the London commercial office, residential and retail sectors, were engaged to refurbish the building converting it from D1 non-residential use into a B2 self-contained Grade A office building.

A layout was chosen that maximises the floor to ceiling height with clear open floor plans yielding some 150 sq m on each of the four floors plus basement. The design provides for flexible space devoid of lobbies so as to aid free-flowing circulation.

‘The building frontage had been badly altered in the past and we wanted to recreate the elegance of the original façade which was achieved using a combination of glazed bricks, bespoke joinery and new steel windows,’ says director of Morrow +Lorraine Julian Morrow.

The project architect Peter Merrett takes up the story: ‘“We selected the Crittall Corporate W20 product to re-create the slim lines of the original 1930s glazing that needed to be replaced, whilst dramatically improving the thermal performance by incorporating double glazed units. The choice was largely driven by a desire to maintain the same pattern of glazing bars to preserve the character of the Marylebone Lane conservation area.”

The Crittall Corporate W20 units were employed front and rear in the refurbishment and the front elevation at ground floor level was reconfigured to reflect the original drawings from the architectural practice Forbes & Tate who designed the building in 1926-27.

The Crittall Corporate W20 units were employed front and rear in the refurbishment and the front elevation at ground floor level was reconfigured to reflect the original drawings from the architectural practice Forbes & Tate who designed the building in 1926-27.

Internally, the designers wished to reveal as much of the original fabric as possible. This was achieved by stripping back finishes and exposing the steel columns of the building’s structural frame. This emphasis on the use of steel was enhanced by the fenestration of the façade, a new steel staircase and the use of steel internal partitions.

‘We used the same Crittall Corporate W20 system to create single glazed screens which in turn allowed for a visual connection between the office space and the stair well, reception area and common parts, ‘ explains Peter Merrett. Referring to the W20 he adds: ‘The product is a design classic which fits seamlessly with our industrial, yet refined interiors.’ The inclusion of fire-rated and acoustic glazing also enhanced the technical performance of the Crittall Corporate W20 system.

The Crittall partition in the reception area acts as a muted backdrop to the focal point of the space, namely a bespoke polished concrete desk designed by Morrow+Lorraine and constructed by Lowinfo Design.

Project data

Location: 116, Marylebone Lane, London W1

Client: The Howard de Warden Estate

Architect: Morrow+Lorraine

Main contractor: Cameron Black and subsequently ARJ Construction