Category Archives: Construction

Shady haven for Marriott Gatwick

Story

In a stunning design by Dexter Moren Architects & Designers, striking bespoke shades from Chelsom hover effortlessly over candy striped seating in the vibrant restaurant of the Courtyard by Marriott hotel at Gatwick Airport’s South Terminal.

In a stunning design by Dexter Moren Architects & Designers, striking bespoke shades from Chelsom hover effortlessly over candy striped seating in the vibrant restaurant of the Courtyard by Marriott hotel at Gatwick Airport’s South Terminal.

Stretched tightly over a sturdy steel drum frame, the soft crimson fabric is lined in gold two-toned patterned silk to provide a rich amber glow throughout the lobby.

Comments Managing Director Robert Chelsom, “Bespoke shades have become a firm favourite with interior specifiers. They give instant impact to any scheme, are extremely cost effective, and are infinitely versatile which gives creative designers the scope to conceive inspired combinations of shape, size and fabrics”.

View Chelsom's profile:

Top notch rainwater systems – from Polypipe

Story

Polypipe extends Elegance range with release of Ogee Notched profile and soil and vent products

Polypipe Building Products has launched its enhanced and extended Elegance cast iron effect uPVC rainwater system with the addition of the revolutionary notched gutter concept for its new Ogee profile to add to the original and already popular half round profile. The Elegance range has been designed in such a way that each profile in the range utilises a common downpipe, making installation and ordering very simple. In addition it has launched a new range of soil and vent products in a matching cast iron effect finish.

The new notched Ogee profile guttering provides a secure fit and counters the problem of gutters becoming dislodged from their retaining clips during warm weather due to heat expansion, making leaky joints a thing of the past. The leading edge of the gutter is notched and the system uses a flexible band clip to secure the gutter. The lugs on the gutter are simply matched to the band clip and snapped into place.

In addition to the notches, Polypipe has included grooves midway between the notches which act as cutting markers when cutting the lengths of guttering. These benefits, in addition to the lightweight construction of the new guttering system, makes handling, assembly and installation as simple as possible for installers.

Simon Green is Polypipe’s Product Marketing Manager for the drainage and water management side of the business: “We’re excited to be able to extend the Elegance range with the new Ogee profile which closely resembles the profile found on original cast iron installations,” he says. “This will make it easy to preserve the traditional look of a period home when replacing the original guttering, but with the knowledge that it will give a more secure fit, be simpler to install and far lighter than the original.”

The new soil and vent range is based on the Polypipe 110mm soil pipe, supplied in 3 metre lengths with a selection of sockets, bends and a vent terminal. The range uses Polypipe’s popular push-fit system, again for quick and easy installation.

Full details of the new extended Elegance rainwater, soil and vent range can be found on its own dedicated web site at www.polypipe.com/elegance and the new system is available from merchants now. Alternatively you can call 01709 770 000 quoting reference “ElegancePRA” and request information, a product leaflet and price list.

View Polypipe's profile:

Hydropath go ‘back to School' with British Gas

Story

Hydropath Holdings has provided training to assist in the education of British Gas engineers. Hydropath, who produce a range of domestic and commercial chemical free water conditioning products, have been involved with British Gas since 1992. Senior members of Hydropath provided a series of training events round the country to British Gas Training Managers. They will, in turn, provide training and information to field engineers, of which British Gas employ over 6,900. The organiser of the training commented, “All the engineers found the training very informative. How physical water conditioners function is a very complex area and there is some scepticism within the industry because the efficacy of some of them is limited at best. Hydropath’s ‘HS38’ unit is the only unit that we would recommend as we have empirical evidence that it actually works. The HS38 is very simple to install to protect a central heating system from limescale, but it has to be placed in the correct location and it was interesting to see a demonstration of exactly why that is.”

Hydropath Holdings has provided training to assist in the education of British Gas engineers. Hydropath, who produce a range of domestic and commercial chemical free water conditioning products, have been involved with British Gas since 1992. Senior members of Hydropath provided a series of training events round the country to British Gas Training Managers. They will, in turn, provide training and information to field engineers, of which British Gas employ over 6,900. The organiser of the training commented, “All the engineers found the training very informative. How physical water conditioners function is a very complex area and there is some scepticism within the industry because the efficacy of some of them is limited at best. Hydropath’s ‘HS38’ unit is the only unit that we would recommend as we have empirical evidence that it actually works. The HS38 is very simple to install to protect a central heating system from limescale, but it has to be placed in the correct location and it was interesting to see a demonstration of exactly why that is.”

British Gas has a number of engineering academies across the country which train engineers in installing, diagnosing and repairing household appliances and central heating systems. An important part of this is educating customers on the importance of avoiding central heating breakdowns. Many parts of the U.K. experience hard water, which can result in scale build up in pipes, reducing the efficiency of the domestic heating system. Limescale compromises the life of the system, increases running costs due to wasted energy, and could lead to a costly repair bill when the boiler breaks down.

British Gas has recommended Hydropath’s domestic HS38 water conditioning unit to its customers for a number of years to improve the efficiency of the domestic boiler with savings on energy bills and preventing expensive breakdowns. The HS38 patented water conditioning system by Hydropath removes limescale by transmitting randomly varying electric fields into the water and the entire plumbing system. The result is the production of nuclei throughout the water system. When the water is heated, the resulting precipitate that usually deposits on hot surfaces grows in suspension and develops as a crystal on the nuclei, which is then washed away in the flow. The treated water is normally able to dissolve existing scale in a few weeks. The HS38 is suitable for use in most domestic applications including open vented combination boilers, mains pressurised unvented and direct fired water heaters, and all domestic appliances throughout the house.

View Hydroflow's profile:

What did we used to call it? 2nd fix – oh yes, I remember that!

Story

If only electricians were able to go to a job, and then just work through until it was done, just like all the other skills on site. But oh no, life’s not like that. First there’s the wiring to do – from circuit protection to outlet back boxes. Then, and usually several days later, when the plasterers and decorators have finished, then and only then, can you return to finish the work by fitting all the electrical accessories and other devices. But all this is about to change with the introduction of a brand new product idea from one of the most established and trusted names in the industry, Electrium, and this new innovation for the electrical industry is called Safety Shield.

If only electricians were able to go to a job, and then just work through until it was done, just like all the other skills on site. But oh no, life’s not like that. First there’s the wiring to do – from circuit protection to outlet back boxes. Then, and usually several days later, when the plasterers and decorators have finished, then and only then, can you return to finish the work by fitting all the electrical accessories and other devices. But all this is about to change with the introduction of a brand new product idea from one of the most established and trusted names in the industry, Electrium, and this new innovation for the electrical industry is called Safety Shield.

By using a Safety Shield on each of the wiring accessories, an installer can do both the first and the second fixes at the same time, or put another way, get rid of the 2nd fix altogether. The Safety Shield simply fits between the back box and the accessory to provide a temporary finished surface that the accessory fixes against in the same way that it would fix against the finished wall.

It elevates the accessory from the wall surface providing working space for plaster patching and decorating, so that the accessories themselves do not need to be removed. It also provides a frame for plaster patching that guarantees a neat finish without the back box ever being clogged up with plaster. It prevents accidental tiling over the fixing lugs as well, eliminating the problem of having to retro-trim tiles in order to fix the accessory in place. It also forms a trim border for wallpaper and a “cutting in edge” for paintwork. And when all other work is complete, the builder can simply loosen the retaining screws, tear Safety Shield away along its pre-formed break points, and retighten the screws.

It elevates the accessory from the wall surface providing working space for plaster patching and decorating, so that the accessories themselves do not need to be removed. It also provides a frame for plaster patching that guarantees a neat finish without the back box ever being clogged up with plaster. It prevents accidental tiling over the fixing lugs as well, eliminating the problem of having to retro-trim tiles in order to fix the accessory in place. It also forms a trim border for wallpaper and a “cutting in edge” for paintwork. And when all other work is complete, the builder can simply loosen the retaining screws, tear Safety Shield away along its pre-formed break points, and retighten the screws.

And if doing away with the second fix isn’t useful enough, it’s the ideal solution for refurbishment and re-wire contracts where it’s necessary to get the power back on and keep the installation fully functional while waiting for other trades to complete their part of the job. For example, the refurbishment of a kitchen usually requires the first fix electrical installation to be undertaken some time before the plaster is repaired and the finishing touches of tiling etc are applied. So, what will the customer do for power and lighting in the meantime? The conventional solution is very labour intensive if continuity of power supply is essential. With Safety Shield, however, it’s simple to keep the power on between trades, doing away with the need for numerous return visits to site to fit and re-fit, and to energise and de-energise circuits, and that means the installer saves time and money while the customer is less disturbed by the process. Electrical safety tests can be carried out and the power can be left on, especially useful on the cooker and the freezer circuits but equally important on lighting and general power.

Safety Shield brings numerous benefits to the all trades working in the refurbishment industry. Connaught Construction has already taken full advantage of the benefits of this amazing innovation. Their Health and Safety offices have approved Safety Shield for use on all ‘Decent Homes’ contracts. These contracts often involve refurbishment of large numbers of social housing units. As part of this service, each home must have power available for the tenants throughout the whole of the 21-day refurbishment timescale, and that power must be provided in a manner that is safe for everyone, including the tenants and the tradesmen working on the property.

Safety Shield brings numerous benefits to the all trades working in the refurbishment industry. Connaught Construction has already taken full advantage of the benefits of this amazing innovation. Their Health and Safety offices have approved Safety Shield for use on all ‘Decent Homes’ contracts. These contracts often involve refurbishment of large numbers of social housing units. As part of this service, each home must have power available for the tenants throughout the whole of the 21-day refurbishment timescale, and that power must be provided in a manner that is safe for everyone, including the tenants and the tradesmen working on the property.

Jonathan Lewis, Site Manager of Bullock Construction Ltd says: “Since using these brilliant, well constructed, bright yellow boxes on all our rewires, I have personally seen a vast improvement to both safety and quality of work. The boxes are instantly noticeable and cover the full area around both light switches and sockets, this means there is no access for fingers to accidentally touch live wires behind the fronts of the

sockets (and we all know how inquisitive children are). There is also a much better finish by the plasterer as they have something solid to work to on all four sides of the socket or switch”

The average saving from using safety shield is estimated at around £132 per dwelling, so if you’re looking for a business opportunity to give you an advantage in these troubled economic times, then by eliminating the 2nd fix, you can make your jobs both more profitable and more competitive all in one go. And then you can laugh all the way to the bank – well if there are any of them left by the time you read this!

The average saving from using safety shield is estimated at around £132 per dwelling, so if you’re looking for a business opportunity to give you an advantage in these troubled economic times, then by eliminating the 2nd fix, you can make your jobs both more profitable and more competitive all in one go. And then you can laugh all the way to the bank – well if there are any of them left by the time you read this!

For further information about Safety Shield contact Electrium Sales on 01543 455000.

View Electrium's profile:

Access control sets new standards at landmark Bristol school

Story

At the newly built, £30 million Abbeywood Community School in Filton, Laidlaw Solutions worked with architects Alec French and BAM Construction to produce a doorset specification which involved the installation of a proximity system using Mifare smart card technology. The architect designed the school to RIBA Stage D+ and was retained as client’s supervisor through to completion. The mixture of both online and offline control units lent itself to the way the school wished to run its security, the online readers giving updates and system changes to each card presented. Hard-wired, online units were connected to the building’s network together with offline, stand alone units which utilised wall readers and magnetic locking. Online wall readers and controllers were interfaced with the automatic entrance doors at reception, which unlock and open when a card is presented to the reader. Over 160 battery powered electronic handle sets were also fitted to classrooms, offices and staff rooms.

Students were heavily involved in how their new school buildings would look and worked with architects and builders as part of their studies. The graffiti style glazing and doorsets in bold, primary colours are a clear result of their involvement. The 920 pupil school has since been granted Specialist School status in Humanities, with English, Geography and Drama being the specialist subjects.

The shift in favour of closer cooperation between manufacturer, specifier, contractor and client has undoubtedly ensured that issues of durability and promises of like-for-like performance are put to closer scrutiny. Speaking of his experience of the project BAM Construction’s Project Manager Andy Syddall said, “Laidlaw scheduled the supply and installation of an access control system for doors throughout the school. While still a relatively new concept for schools, the support Laidlaw provided throughout demonstrated their experience of managing projects of such a scale”.

The school was chosen by South Gloucestershire Council as the first to receive funding from the Department for Children, Schools, and Families as part of the Building Schools for the Future programme. It is just one of a long list education projects for which Laidlaw access control, doorset and handrail systems have been chosen.

View Laidlaw's profile:

FROZEN PEAS GET THE WATERMATIC TREATMENT!

Story

When you stand in your kitchen and look at a one kilo bag of frozen peas or petit pois, you realise that 40,000 tonnes of peas is an awful lot of peas by anyone’s standards, but that’s the quantity of the little round green chaps that flood through Birds Eye’s pea processing plant on the banks of the River Humber, within a stone’s throw of the quite beautiful Humber Bridge, just outside Hull.

Grown predominantly on the Lincolnshire and Yorkshire Wolds and transported to Hull for processing and packing, the whole ‘pea’ process demands huge quantities of water – from one of the hardest water areas in the UK, and in order for the processing machinery to run smoothly, without the problems associated with limescale build up, they need a little help from technology.

One of the bits of technology the have turned to, to achieve this is Watermatic’s KalGuard + system. Watermatic is part of the Sentinel Group, and is increasingly offering many large businesses a way of reducing their energy consumption by reducing limescale build up in their plant and systems. Untreated limescale in hard water areas of the country – that’s more than 60% of the UK – results in a need to use far more electricity than should be required for clean, scale free plant and hot water systems and in Birds Eye’s case even more problems associated with the freezing technology they utilise at their plant.

The Birds Eye pea line operates for just 6-8 weeks every year when the peas are picked and processed as rapidly as possible to capture the freshness of the newly picked peas. All the water coming into the factory comes through the KalGuard + unit before heading on down the line for secondary treatment at the plant’s massive commercial water softener installation, before heading off to the refrigeration and boiler plant in the factory.

Straightforward to install, KalGuard ‘+’ is an in-line powered electrolytic water treatment device that manages limescale within a system. The unit incorporates a simple to use, yet sophisticated controller to match the level of treatment to suit the systems water hardness conditions producing a measurable “residual” effect throughout the system, and as a result in independent testing at Cranfield University, has been shown to reduce limescale formation on heat transfer surfaces by up to 80 percent.

Kalguard + doesn’t soften the water – it simply alters the nature of the water to contribute to the reduction in limescale ‘fall out’ from the water onto heated surfaces – in a process known as retro-precipitation. Amongst other businesses that have already installed KalGuard ‘+’ equipment to protect their systems and reduce their energy consumption are well known names such as BMW, Whitbread and KrispyCreme Doughnuts!

Watermatic’s KalGuard ‘+’ units are proving hugely beneficial around the UK to hotels, nursing homes, leisure centres, food processing businesses, offices and retail outlets and finding a warm welcome across the globe – in places such as Cyprus which has horrendously hard water and in the Middle East which also suffers the problems of hard water on a major scale.

View Watermatic's profile:

NICEIC and Megger join forces to offer the Golf Classic 2009

Story

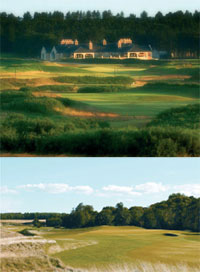

You have the opportunity to win an all expenses paid weekend in the luxurious surroundings at Archerfield, playing two rounds over the outstanding Fidra and Dirleton Links.

You have the opportunity to win an all expenses paid weekend in the luxurious surroundings at Archerfield, playing two rounds over the outstanding Fidra and Dirleton Links.

Contribute to EEIBA’s activities by playing golf

- Entrance fee of £65 per pair includes

- Coffee and bacon roll on arrival

- 18 holes of golf

- Two course meal

- Golfer’s Goody bag

Be crowned NICEIC Golfers of the Year

This exclusive event comprises 8 Regional qualifying rounds in June & July with the Grand Final to be played in September at the prestigious Archerfield Links on the renowned East Lothian coast of Scotland. Winners of the regional rounds will receive an all expenses paid weekend in the luxurious surroundings at Archerfield, playing two rounds over the outstanding Fidra and Dirleton Links, the eventual winners becoming the NICEIC Golfers of the Year.

The NICEIC is a committed supporter of the EEIBA’s activities and will be making a contribution from the funds raised by the tournament.

8 regional rounds

The regional qualifying rounds will each feature a substantial prize table and will be held at the following venues:

Leeds Sand Moor Golf Club – June 10th

Cheshire Delamere Forest Golf Club – June 11th

Birmingham Kings Norton Golf Club – June 15th

Cambridge Gog Magog Golf Club – June 16th

Belfast Bally Castle – June 19th

Lanark Lanark Golf Club – June 22nd

Bristol Bristol & Clifton Golf Club – July 2nd

Wokingham Sand Martins Golf Club – July 3rd

A Stableford pairs event

The NICEIC Classic will be a Stableford pairs event and is open to all NICEIC contractors and their guests with a valid handicap certificate.

The winners of the regional qualifying rounds will be invited to compete in the Grand Final at Archerfield Links where accommodation and green fees are all covered within the guidelines laid down by the R&A on Amateur Status.

Spaces are limited

Places at each of the qualifying events are limited and will be allocated on a strict first-come first-serve basis.

To reserve your place :

e-mail: classic@niceic-golf.com

call: 0845 123 3839

View Megger's profile:

Zinc bridges old and new on Stockport campus

Story

Austin Smith Lord’s design of the £100m Stockport College campus redevelopment has seen the use of 8,000m2 of VMZINC flat lock zinc tiles, together with interlocking and sine wave horizontal panels. Work on the former St. Thomas’ Hospital site and the retention, restoration and creative re-use of some of the most architecturally and historically significant former Victorian Workhouse buildings will ultimately create a collegiate quarter.

The redevelopment scheme will see the workhouse transformed into staff accommodation and a welcome centre. New workshops back directly onto the A6, so the choice of high quality cladding materials, including glass and zinc, was driven by the desire to create a landmark for the College.

The architect has utilised ANTHRA (black) VMZINC on all facades and the different styles of VMZINC panels break up the visual impact within a uniform overall style. The combination has enabled a frontage to be created which will enable the Motor Vehicle and Motor Cycle departments to be visible from the A6.

The workhouse yielded a string of historic artefacts in the course of construction including children’s shoes, a diet regime board for ‘inmates’, marbles, clay pipes, walking sticks, plates, Christmas cards, newspapers dating from 1889 and even hair samples. Most were in remarkably good condition and looked as though they had remained untouched for well over a century.

View VM Zinc's profile:

STELRAD RADIATORS – OFFERING A SOLUTION ……IF YOU'RE VERTICALLY CHALLENGED!

Story

Stelrad Radiators has the answer if you’re looking for a modern alternative to traditional radiators that can give even the smallest room something of a ‘wow factor’.

Stelrad Radiators has the answer if you’re looking for a modern alternative to traditional radiators that can give even the smallest room something of a ‘wow factor’.

There’s a tendency to think that all radiators have to be long and horizontal – that’s what we’ve all got used to over the decades, but there really isn’t a problem with thinking laterally…… and going vertical.

Stelrad Radiators has introduced a range of environmentally friendly, extremely efficient vertical radiators that not only look good and give you that essential added flexibility, but operate brilliantly with the new renewable heat systems such as heat pumps and solar thermal systems, due to their increased surface area, which all contributes to keeping your rooms cosy and warm even with lower system operating temperatures.

Stelrad has introduced new vertical versions of their very popular Vertex, Planar, compact with Style and Classic Column radiators – offering vertical options for every type of homefrom renovated older properties to the most modern of new building designs. These elegant and exciting vertical radiators complement existing Stelrad horizontal radiator ranges perfectly – enabling you to select the right options for each room, whilst ensuring matching compatibility throughout the home. The Vertex for example, complements both the Stelrad Compact and Stelrad Elite ranges, whilst the Concord Vertical and Concord Slimline radiators match the horizontal Concord range, and so on.

“The vertical option is excellent news for designers, architects, installers and of course homeowners – looking for convenient and stylish warmth throughout a home,” says Chris Humphreys, Stelrad Radiators marketing director. “They offer the opportunity to bring some creativity to a home – however much space there may be from room to room – and whilst they are perfect for traditional boiler-driven heating systems they’re simply ideal in conjunction with renewable energy technology too.”

View Stelrad's profile:

Wholesalers rewarded for E-commerce achievement

Story

Five electrical wholesalers have won awards for their use of the internet-based ordering system operated by leading electrical manufacturer, Eaton. The Award is based on the percentage of orders placed through Eaton’s on-line ordering system, Global Vista on the Web, together with the level of staff training and use of Eaton’s associated Distributor Resource Centre.

Five electrical wholesalers have won awards for their use of the internet-based ordering system operated by leading electrical manufacturer, Eaton. The Award is based on the percentage of orders placed through Eaton’s on-line ordering system, Global Vista on the Web, together with the level of staff training and use of Eaton’s associated Distributor Resource Centre.

The awards, presented by region went to:-

- TN Robinson, Stockport (North)

Edmundson Electrical, West Bromwhich (Midlands)

WF Electrical, Dagenham (South East)

Wilts Wholesale, Trowbridge (South West)

Richmond Electrical, Dublin (Scotland and Ireland)

The awards, marking the first two years of Global Vista on the Web, were presented by Nigel Birch, E-Business and Distribution Marketing Manager for Eaton.

Global Vista on the Web, puts wholesalers in control of their orders. It enables them to access the Eaton system and view availability and prices of products; enter, review and change orders; and check the status of orders already placed. An order is linked directly to Eaton’s global manufacturing system, initiating a chain of actions going right back to the factory and including warehouse inventories, demand planning, pricing and invoicing.

The system also includes a web-based Distributor Resource Centre that gives Eaton’s distributor customers access to a wide range of resources including the latest distributor mailings, PDF downloads of product information, training information, and links, templates for trade counter support and marketing communications information.

The system also includes a web-based Distributor Resource Centre that gives Eaton’s distributor customers access to a wide range of resources including the latest distributor mailings, PDF downloads of product information, training information, and links, templates for trade counter support and marketing communications information.

“We are delighted to recognise the efforts of these five wholesalers and, indeed, all our distributors who have embraced the concept of ordering through our web portal” says Nigel Birch. “We have received over 100,000 order lines through Global Vista on the Web and we will continue to expand and adapt our e-business offering to the distributor channel.

“In these demanding times it is important for us to reduce administration time and give our customers as much information as possible, as quickly as possible. We have seen an improvement in our delivery performance together with a reduction in debit notes and an overall improvement in cycle times” says Mr. Birch.