Category Archives: Construction

Profile Evolution From Marshall-Tufflex

Story

Odyssey Trunking has a unique curved profile which is ideally suited to projects where aesthetics are of prime importance. Its ground-breaking design will allow decision-makers to specify a containment system on its appearance, confident that it offers the most stylish of systems available today and that it is supported by all the functional excellence expected from Marshall-Tufflex products.

Odyssey Trunking has a unique curved profile which is ideally suited to projects where aesthetics are of prime importance. Its ground-breaking design will allow decision-makers to specify a containment system on its appearance, confident that it offers the most stylish of systems available today and that it is supported by all the functional excellence expected from Marshall-Tufflex products.

The new clip-on action of the lid is unique, snapping on to the rear of the base and allowing the system to follow the irregularities of the fixing surfaces in order to create superbly smooth lines.

Fittings are exceedingly secure because of this clip action and the extensive range of moulded fittings minimise the need for external couplers, a design feature that once again, contributes to creating the aesthetic appearance of the trunking body.

Fixed horizontal bends have been designed for maximum aesthetic achievement but there is also the option of some very smart adjustable bends to accommodate the problems thrown up by building intolerances. The external adjustable bend also has a unique locking facility built-in to the fitting and the installation of Odyssey becomes easier and faster with the addition of in-built cable trays.

All fittings have bend radius cable control for Cat 6 compliancy, Steel Dividers are available to protect data from power (complying with Information Technology Standard BS EN 50174-2) and Marshall-Tufflex is alone in being able to offer a Copper Spray screening for total protection against EMI.

You can take a look at Odyssey on www.marshall-tufflex.com/odyssey and while you’re there, try your luck at the Odyssey Invaders Game – check your score against the rest of the world and see if you can make it to the top three!

View Marshall-Tufflex's profile:

Roof window trend towards the L-shaped window

Story

With greater use of roof windows for their contribution to interior design, there has been a marked trend towards use of windows used in combinations and L-shaped windows in particular. Such windows are equipped with a locking mechanism to prevent accidental opening by children. The vertical element is typically installed beneath a standard roof window and linked together using a vertical jointing module. This significantly increases the amount of light entering a room and increases the field of view. The roof window handle is positioned at the lower part of the sash enabling easy operation.

With greater use of roof windows for their contribution to interior design, there has been a marked trend towards use of windows used in combinations and L-shaped windows in particular. Such windows are equipped with a locking mechanism to prevent accidental opening by children. The vertical element is typically installed beneath a standard roof window and linked together using a vertical jointing module. This significantly increases the amount of light entering a room and increases the field of view. The roof window handle is positioned at the lower part of the sash enabling easy operation.

Fakro Managing Director Noel Shanahan commented “L-shaped roof windows are the ideal alternative to dormers as they are quicker to fit and avoid detailing problems. By extending the window line into the wall, they give greater scope to the designer and householder, while providing a stylish appearance at lower cost”. Products are even available in conservation style, with the traditional sash bar down the middle of the window, and black metal cladding and flashing.

View Fakro's profile:

OSMA UFH Electric Mat – Genius!

Story

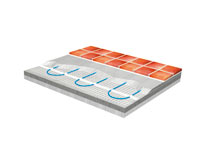

With more than a third of house buyers adding underfloor heating to their top five wish list, the new OSMA Underfloor Heating (UFH) Electric Mat system from Wavin will come as a welcome addition to its already extensive range of ‘Genius’ UFH options.

With more than a third of house buyers adding underfloor heating to their top five wish list, the new OSMA Underfloor Heating (UFH) Electric Mat system from Wavin will come as a welcome addition to its already extensive range of ‘Genius’ UFH options.

The new UFH Electric Mat systems are available in 100W/m² and 150W/m² to accommodate different floor structures and are the perfect option for the renovation and refurbishment market.

The Electric Mat system complements the existing OSMA UFH range giving home owners complete flexibility when it comes to choosing the right UFH option for their individual needs.

The Electric Mat 100 is suitable for all types of subfloor including timber and can be used under almost all floor finishes including tiles, stone, vinyl, wood, laminate or carpet. The Electric Mat 150 is the perfect choice where a higher output is required and must be installed on a solid subfloor using a ceramic floor finish.

The benefits of the UFH Electric Mat are clear. Its thin construction, measuring just 5mm, makes it a truly versatile option for projects that don’t have the depth of space for traditional screeded UFH options – usually requiring 122mm build up from the subfloor. The total overall floor build up thickness using the Electric Mat could be as little as 6mm. Not only that, it’s fast and easy to install and requires no special skills to complete the mat installation.

Awkward shaped rooms or small areas such as bathrooms are ideal room scenarios for the Electric Mat. The self adhesive glass fibre mesh can be easily cut to accommodate curves and corners in the room. The Electric Mat 100 is available in two metre and four metre lengths and the Electric Mat 150 is available in six metre and ten metre lengths – providing complete flexibility for every room type.

The new Electric Mat is recommended for use with the OSMA UFH PRT-E dual sensor thermostat to give the home owner complete control over its use.

The Electric Mat system forms part of the six OSMA UFH options available from Wavin, along with Staples, System plates, Pocketed polystyrene, Foiled polystyrene and Modular chipboard, providing an option to suit all buildings and floor constructions. The ‘Genius’ OSMA systems have been developed using the cleverest technology but are still simple to understand and easy to install. Even the most basic OSMA UFH system, staples, works on the genius principle and has been designed to give full flexibility for screed floors even if small or irregularly shaped.

View Wavin UK's profile:

Megger’s New Catalogue Is A Testasaurus For Contractors!

Story

Megger has published a new and extensively updated version of its indispensable Electrical Test Equipment catalogue for contractors, which is a valuable aid in helping users to comply with the testing requirements prescribed by the 16th Edition of the IEE Wiring Regulations.

Megger has published a new and extensively updated version of its indispensable Electrical Test Equipment catalogue for contractors, which is a valuable aid in helping users to comply with the testing requirements prescribed by the 16th Edition of the IEE Wiring Regulations.

The new catalogue particularly highlights products that have been introduced since the last edition. Among these are the innovative and unique LTW range of two-wire non-trip loop testers, fast-selling MFT1552 multifunction testers and LT300 high-current loop testers. The catalogue also includes useful guidance regarding fused test leads and test certification software.

For every product range, the catalogue offers a detailed overview, with information about key product features and the benefits they provide to users. This is accompanied by full specifications for all models available in the range, together with ordering information and colour photographs.

Copies of the new catalogue can be obtained by calling the Megger customer support line on 01304 502101, or by visiting www.megger.com.

View Megger's profile:

Marks & Spencer Gives Dulux Trade Ecosure the Green Light

Story

As endorsements go, they don’t get much bigger than Marks & Spencer, but that’s exactly what Dulux Trade, the industry leading manufacturer of quality paint systems, received at EcoBuild for their latest innovation, Ecosure.

As endorsements go, they don’t get much bigger than Marks & Spencer, but that’s exactly what Dulux Trade, the industry leading manufacturer of quality paint systems, received at EcoBuild for their latest innovation, Ecosure.

Dulux Trade is the first major paint manufacturer to have taken significant steps towards creating a credible environmentally sustainable paint product for the professional market. Ecosure has been specifically formulated to have demonstrable reductions in embodied carbon and Volatile Organic Compounds (VOC), two key sustainability criteria.

Developed using an approach based on scientific rigour, these reductions have been achieved without compromising on performance. Additionally, accurate measurement of these reductions has been made possible by the use of an ‘Environmental Impact Analyser’, developed in conjunction with Forum for the Future – the leading independent sustainability experts.

Speaking at EcoBuild 2008, Crispin Burridge, Sustainability Manager for Marks & Spencer, said: “The idea of an environmentally sustainable paint has been around for some time, but has been difficult to use on larger scale projects. I'm delighted to see Dulux Trade has risen to the challenge by investing time and money into producing such a paint product. We particularly welcome the opportunity to specify paints for our stores with lower VOCs and a reduced carbon footprint that support a number of our Plan A commitments.”

David Shepherd, Brand Manager for Dulux Trade, commented: “Ecosure signifies a real milestone for us. It is a ‘step towards greener’ and our acknowledgement that we are embarking on a journey toward a more sustainable future. We need, and fully intend, to move toward more environmentally sustainable products and ways of working.

“It is fantastic that Ecosure is already getting such a positive reception from existing customers and key UK firms such as Marks & Spencer. Within the retail arena, Marks & Spencer is driving the environmental sustainability agenda. Their commitment to this issue, highlighted by their bold ‘Plan A – because there is no Plan B’ 5 year strategy to tackle the biggest issues facing their business and the globe, is unquestionable. It is great that we can help them achieve this goal.

“Being green is no longer an option and the emphasis placed on companies to become environmentally friendly can only intensify. UK businesses need to make the investment now to ensure they are meeting sustainability targets and working within increasingly green environments.”

Ecosure is available in Pure Brilliant White and an extensive colour range from the Dulux Trade colour offer, ensuring that you don’t even need to compromise on design.

Crispin concluded: “We hope that Ecosure will help achieve a more sustainable specification for M&S stores, which is why we are trialing it at our new White City store, which is due to open at the end of the year. On successful completion there, we intend to have it included as part of our paint specifications.”

Ecosure will be available from selected Dulux stockists at the beginning of May. For more information visit www.duluxtrade.co.uk/ecosure

View Dulux Trade's profile:

A complete process for a complete solution

Story

Marflow Hydronics has launched the Remote Commissioning concept, an innovative approach designed to simplify the installation and commissioning of fan coil and chilled beam systems. It is able to significantly reduce the cost of installing such systems, while also ensuring they operate at optimum efficiency.

Marflow Hydronics has launched the Remote Commissioning concept, an innovative approach designed to simplify the installation and commissioning of fan coil and chilled beam systems. It is able to significantly reduce the cost of installing such systems, while also ensuring they operate at optimum efficiency.

One element of the concept is the use of addressable pressure independent 2-port valves from Belimo, linked to a BMS or local controller. This enables valves to be adjusted remotely from a central PC or other control device without the need for an engineer to enter the ceiling void. Consequently, as well as speeding up commissioning, it also enables quick and easy re-configuration of systems – to accommodate layout changes within the space, for example.

“Most people don’t realise that centralised, remote control, which is widely used in other building services systems, can be applied to chilled and hot water systems,” explained Marflow’s Martin Lowe. “However, the Remote Commissioning approach is about more than new valve technologies. It is designed to give the specifier and installer complete control of the project from start to finish. As such it also incorporates centralised management of valve information and hydronic performance data, advanced pre-fabrication techniques and innovative commissioning processes using Marflow’s single station balancing method.

“At its heart is a recognition that design, installation and commissioning practices in many projects have failed to keep pace with key developments in the industry. These developments include the growth of design and build, skills shortages and the increased use of multi-national labour forces, and the opportunities provided by modern valve technologies.

“As a result, this outdated approach is failing to deliver the best result for the contractor and the end client in many projects,” he continued. “Our approach seeks to rectify the current fragmented approach to system design by creating a single system from one source; a complete process that equals a complete solution,” he added.

The system can be divided into several stages:

Smarter design

Attention to detail from the start of the project and anticipating problems before they occur can optimise the use of site labour, compensate for inherent skills shortages or inexperienced operatives and minimise the risk of installation errors.

Management of information

Many problems arise from poor communications between members of the project team The Marflow system brings all valve information and hydronic performance data into a single, purpose-designed spreadsheet package that is continually updated, with any changes being distributed to all relevant parties.

Innovative installation

Rather than seeing pre-fabrication as simply a way of transferring site work to another location, the Marflow approach takes full advantage of the benefits of pre-fabrication. These include use of innovative valve assemblies, location of all valves for each zone in a single location that also contains information about the system, facilitation of single station balancing (see below), pre-insulation of the manifold box and use of pre-insulated, flexible pipe.

Reducing installation errors

Pre-fabricated assemblies are supplied complete with all components, using labelling and colour coding of connections to ensure correct installation. Full instructions are provided, using diagrams so that language is not an issue.

Single Station Balancing (SSB)

Unlike proportional balancing, which is laborious and time consuming, the SSB method uses a subtraction technique to identify problem valves. This is based on knowing the design flow rates for each individual valve and, therefore, the total flow rate for that fan coil group.

Assuming all the valves are functioning correctly, isolating each valve will have a predictable effect on the total flow rate for the remaining valves. Where an unexpected result is observed it is a simple matter of elimination to quickly identify the valve that causes this, enabling the commissioning engineer to home in on the problem area.

SSB is discussed in more detail in the background notes

Innovative valves and controls

The Remote Commissioning concept takes full advantage of the functionality of Belimo’s pressure independent two port control valve, linked to a BMS fan coil or chilled beam controller, and an actuator that can be set from a remote location to the required position to give design flow rates. This allows only two valve sizes and four valve configurations of flow and return to be used in achieving the design performance.

The BMS controller, housed in its own case, can be wired to the actuator via pluggable leads and sockets within the assembly. A power plug socket is provided for mains power to the controller and to allow switched power to the fan on the fan coil unit. A plugged cable is also provided from the controller to the fan coil unit supplying power and the temperature sensor. The communication cable to the BMS is also a pluggable connection.

In summary, the Marflow system is designed to achieve the following:

- Simplified installation and commissioning by design

- Full exploitation of the benefits offered by the latest valve technologies

- Efficient management and sharing of critical system information

- Regular updating of information to all parties to reflect design changes as the project proceeds

- To enable smaller contractors to realise all of the benefits that are often confined to larger, better-resourced companies through the innovative use of information technology

- Quicker installation with less site-work through advanced pre-fabrication techniques

- Reduced risk of installation errors through innovative colour coding and labelling techniques

- Faster, more accurate commissioning using innovative ‘single station balancing’ methodology

- Use of the latest addressable valve technologies to allow valves to be adjusted from a remote location, without needing to enter the ceiling void.

View Marflow Hydronics's profile:

Stunning Gallery Makes Its Mark

Story

Hamilton Litestat?s Digital Mercury lighting control system has been featured in the new premises of Philip Mould Gallery in Dover Street, West London, to provide effective scene setting capabilities that maximise the visual impact of the gallery.

Hamilton Litestat?s Digital Mercury lighting control system has been featured in the new premises of Philip Mould Gallery in Dover Street, West London, to provide effective scene setting capabilities that maximise the visual impact of the gallery.

Special wiring accessory plates were also manufactured by Hamiltons for this project using their Henley range in order to provide triple plates combining 13amp sockets with data outlets or 13amp sockets with 5amp lighting circuit outlets. These were finished in a special antique bronze to complement the gallery?s stylish interior and to allow the plates to be recessed, unobtrusively into the stone skirting.

Philip Mould is a world renowned art dealer that regularly appears on the television programme ?Antiques Roadshow?. When he decided to move from his first floor gallery in Dover Street to a 3000 square foot ground floor gallery, on the opposite side of the road, he commissioned Charles Marsden-Smedley, to design his new gallery. This is the third gallery project that Charles has undertaken for this client in 18 years. Specialising in the design of museums, galleries and exhibitions, as well as top-end lighting designs, he has been responsible for many prestigious projects in Windsor Castle, Queen?s Gallery in Buckingham Palace, Tower of London, and the new Central Hall in The National Maritime Museum, to name but a few.

?The brief for this project was to produce a gallery with a twenty year lifespan that not only allowed Philip Mould to conduct his business effectively?, said Charles, ?but at the same time would clearly demonstrate how paintings of any period can look good in a contemporary interior. As the building is located in London?s most important art dealing area, a really impressive frontage was required to draw the eye away from the other galleries in the road.?

?The brief for this project was to produce a gallery with a twenty year lifespan that not only allowed Philip Mould to conduct his business effectively?, said Charles, ?but at the same time would clearly demonstrate how paintings of any period can look good in a contemporary interior. As the building is located in London?s most important art dealing area, a really impressive frontage was required to draw the eye away from the other galleries in the road.?

To satisfy the client?s brief Charles put together a professional team to prepare a tender for a main contractor. This included M & E consultants, Wilson and Partners with whom Charles had worked on a number of other occasions. It was part of their role to manage M&E services including the air conditioning, fire detection, electrical installation and security system.

Having stripped out the area back to its bare shell, Charles set about sub-dividing the space to create separate rooms with a very contemporary feel which included; a front gallery, side gallery with reception desk, showing room with picture rack areas and pocket doors to create a private meeting area/dining room and a long gallery which is top lit with natural daylight. There are also three top lit offices, a room for Philip Mould, a Central Office, along with a library/office and kitchen and toilet facilities.

All the air-conditioning equipment, fire detection, security and lighting were concealed above newly created suspended ceilings. In the front and side galleries these ceilings stop 1m short of the walls to allow the hanging walls to extend up to the existing slab. This was done for two reasons, firstly it allows for the largest full-length portraits to be hung and also it concealed the picture lighting to avoid any distraction when looking at the paintings.

All the air-conditioning equipment, fire detection, security and lighting were concealed above newly created suspended ceilings. In the front and side galleries these ceilings stop 1m short of the walls to allow the hanging walls to extend up to the existing slab. This was done for two reasons, firstly it allows for the largest full-length portraits to be hung and also it concealed the picture lighting to avoid any distraction when looking at the paintings.

By using the medium of glass to create one large shop window, Charles was able to make the gallery highly visible from the road. The interior layout, with its clean, contemporary shapes, along with the careful use of lighting, made the gallery come to life, particularly after sunset.

Commenting on the layout Charles said ?It has been designed to maximise views of the paintings, creating the longest possible vistas and good sight lines. At night there is a view from the street right through to a painting on the back wall of the Central Office and another of the two ends of the Long Gallery creating lots of interest and a powerful focal point.?

The intricate layout of the gallery required an effective lighting scheme to create the sense of space and drama that would attract the buyer?s eye and achieve the client?s original vision. To do this, track-mounted spotlights or recessed gimbals by Remote Lighting were used to create the desired picture lighting. The use of a hand-held remote controller allows for the individual luminaires to be focused, dimmed and turned on and off. The advantage of the Remote Lighting fittings is that they allow maximum flexibility for the constantly changing hangs and they avoid the use of step ladders to adjust the lighting each time a picture is changed.

Overall control of the lighting was achieved with Hamilton?s Digital Mercury lighting control system. This system has overall control of the gallery?s ambient lighting and the ability to override the Remote Lighting so that the track spotlights and gimbals could all be dimmed during night hours, or turned off when not required.

Overall control of the lighting was achieved with Hamilton?s Digital Mercury lighting control system. This system has overall control of the gallery?s ambient lighting and the ability to override the Remote Lighting so that the track spotlights and gimbals could all be dimmed during night hours, or turned off when not required.

For ease of use the system has featured a global control unit at the main entrance to the gallery so that all of the lighting can be raised, lowered, or turned-off by the touch of the appropriate button. Digital Mercury has also included a security mode which is operated on a timer mechanism. This automatically lowers the lighting to a pre-set level, at a set time, and then repeats this process some hours later to further reduce the amount of power usage when the gallery is unoccupied. In the event of a power cut, Digital Mercury has been designed to automatically reset itself, once the power source is reinstated, thus avoiding the loss of the set programmes

In the event of an alarm activating the security system has been linked with Hamilton?s lighting control so that it automatically brings the lighting up to full power to enable the security cameras to track any intruders.

To allow for easy presentations to invited groups, the gallery has incorporated a projector and screen which are concealed within the ceiling void when not in use. These can be lowered and operated by using a remote device. This system has also been interfaced with Digital Mercury so that the lighting can be easily controlled to suit the presenter?s requirements.

This lighting control system features digital technology to mix the various channels of light, in order to create the required scenes and lux levels. By using intelligent dimming, the user is able to alter the stored lighting scenes, using the remote control, thereby making it quicker and cheaper to reconfigure the system. This is a major advantage for the gallery as once the system is installed it doesn?t need a specialist engineer to alter the settings as the gallery staff can reprogram it themselves to suit their own requirements. Once a scene is programmed into the system, Digital Mercury remembers the setting and then recalls it each time the appropriate controller is used. To make Digital Mercury even more user friendly Hamilton Litestat has included inbuilt fade rates to enhance the system?s capabilities.

?Our client is delighted with the overall effect achieved for the gallery?, said Charles. Since it opened at the end of last year it has become the talk of the art-dealing West End. The use of Hamilton?s lighting control system provided a very flexible solution which has played its part in enhancing the visual appeal of the gallery. Its practical design makes it very user-friendly, so that it will be able to keep pace with this client?s constantly changing requirements.?

View Hamilton-Litestat's profile:

New Bollard Rises to the Fore

Story

The Bollard People, ATG Access announce the imminent launch of a brand new bollard, aimed at the self install and professional access control marketplace this product is set to make waves in the industry.

ATG Access currently has a large share of the global market for rising bollards but has been aware, as the bollard market place matured in Europe that they needed to offer something to the re-seller or installer marketplace. This bollard is it.

This new product will be an off the shelf automatic bollard which allows the installer to utilise his own access control and peripheral accessories.

The reason this will shake up the industry? A bollard designed and manufactured by ATG Access to ISO 9001:2000 with:

- Modular design for serviceability

- Plug and play interface for access control

- Optional Gem GlowTM lighting cap

- High speed service interchange

- Simple installation

- Range of optional accessories

- Safe and reliable light source using Lite SafeTM design.

And all for under £1500 (approx ?1800)* ex works for a bollard only. See the most exciting thing in bollards since the SP1000 stopped a truck, at InterTraffic Amsterdam, Hall 1, stand number 615. Then at IFSEC at the NEC in May.

View ATG Access's profile:

Mitsubishi Electric Targets Westminster With Green Message

Story

Environmental technology manufacturer Mitsubishi Electric has just taken its Green Gateway Initiative to the policy and planning decision makers within central and local government at a special environmental conference.

Sales Director Deane Flint presented the initiative to the Energy & Environment 2008 Conference in Church House Conference Centre in Westminster on the 17th June. The event was chaired by John Vidal, Environment Editor of the Guardian and saw presentations from manufacturers and industry bodies in addition to speeches from both Gregory Baker MP, the Shadow Minister for Climate Change and the Environment and Phil Woolas MP, Minister for the Environment.

“It was interesting being on the podium in front of over 250 delegates from all sections of industry and government,” explained Deane Flint. “I had been asked to give a perspective from the construction industry’s point of view and highlighted not only what can be done on the built and to-be-built environment, but also where government can help more to provide clarity and definition.

“What is encouraging is that there is a level of consensus that we need to start acting together and a lot of interest from industry and policy makers in what is a significant challenge as well as a great opportunity for the construction industry.”

For more details on the Green Gateway Initiative visit call Mitsubishi Electric on 01707 282880 or visit www.greengatewayinitiative.co.uk.

View Mitsubishi Electric's profile:

Energy efficiency through better motors

Story

Precise controllability, more reliability and less energy ? new energy efficient motors in fans deliver direct benefits to the HEVAC industry. Paul Kilburn, Vent-Axia?s Group Sales and Marketing Director explains what this means for ventilation

Precise controllability, more reliability and less energy ? new energy efficient motors in fans deliver direct benefits to the HEVAC industry. Paul Kilburn, Vent-Axia?s Group Sales and Marketing Director explains what this means for ventilation

The Government, in its national quest to reduce our greenhouse gas emissions, has sharpened its focus on the energy performance of buildings. In the drive for better air quality, greater energy efficiency and the reduction of carbon emissions, the latest editions of Building Regulations Documents F&L are now beginning to take effect.

Building Regulations F & L have signalled a big shift towards energy efficient buildings and have set the standard for the maximum carbon dioxide emissions for whole buildings. This performance-based approach offers designers the flexibility to choose suitable solutions which allow for adequate means of ventilation for people in the building, and which are energy efficient, cost-effective and practical. However, the revisions to Part L have raised performance standards to a level that has provided a strong incentive to designers to consider low carbon systems, not least the development of the SAP Appendix Q process for ventilation, which affects postively the role of mechanical ventilation with or without heat recovery and with DC motors on Dwelling Emission Rates.

In the context of increasingly demanding environmental legislation and rising awareness of the need to reduce energy consumption, energy efficient motors look set to expand their share of the market for industrial, commercial and residential ventilation.

There are two main types of electric motors: direct current (DC) and alternating current (AC). Compared to AC motors, DC motors are faster, more efficient and offer more accurate speed and position control. Moreover, while AC motors produce an audible 60 Hz ?hum,? DC motors are much quieter. DC motors are also usually smaller than AC motors, providing manufacturers with the opportunity to design applications that are smaller with different styles and looks.

Generally, DC motors draw less current (about two to four times less) and therefore consume less power compared to an AC motor with equal output power. DC motors also work better for situations where speed needs to be controlled as they have a more stable and continuous current. DC motors are finding their way into new products and applications that previously used AC motors exclusively.

Vent-Axia has been instrumental in using LoWatt DC technology leading, the market for several years. Vent-Axia believes in practical action and has been spearheading the campaign to deliver more affordable long life ventilation. Vent-Axia?s residential and commercial product ranges are all available with DC technology, improving performance, reducing running costs, extending fan life whilst ensuring reliability.

However, Vent-Axia is now using a new revolutionary motor, called ?EC? that offer the efficiency and speed control benefits of DC, with built in AC to DC conversion and speed control.

EC motors are a better, more efficient motor at every speed but it doesn’t stop there. Utilising EC motors in fan systems offers many benefits; for example, EC fans can use as little as a third of the energy of industry standard AC fans. EC fans offer easy, quiet and efficient speed control and all the electronics are built into the fan making other components more efficient. The greater reliability and longer life of DC and EC motors has the further advantage of extending the life of insulating materials, lubricants and bearings, thereby cutting the cost and inconvenience of return service visits.

EC fans save energy and increase the longevity of the products, whilst reducing lifetime costs, thereby adding value. They significantly lower noise and generate less heat than conventional AC and DC motors. The EC motor?s compact design makes it easy to install in any position, which opens up this motor to a wide range of possible applications.

As technologies become more advanced and cost-effective, we should expect to see more innovative low energy fan systems introduced to the market featuring different designs as well as improved performance. Across Europe, energy efficient fan systems could save almost 200 billion KWh a year of electricity.

And with indoor environmental control accounting for almost half our national energy consumption, it?s clear that the HEVAC industries can make a significant contribution to achieving national targets for reduced carbon emissions with LoWatt DC and EC technology*.

Simply using fans with high efficiency could save industries in Europe as much as 2.6 billion Euros a year in energy costs. By optimising the motor, impeller and the fan housing, 60% less energy is needed than with comparable AC motors.

Thinking outside the box is somewhat of a Vent-Axia forte and Low Watt energy efficient DC and EC fans are an example of the mindset that has created a range of solutions to meet the changing requirements of the industry. Vent-Axia is constantly pushing the HEVAC boundaries of conventional thinking. Vent-Axia?s innovative new on-demand ventilation system, Sentinel utilises the latest EC motor technology to respond to the exact ventilation requirements of a room at any one time, thus drawing a low specific fan power, designed to meet modern building management control requirements. In addition, our range of Heat Recovery and Central Mechanical Extract products share the same benefits.

This technology is also infinitely speed controllable and offers increased energy savings across the complete speed control range when compared to conventional inverter drive solutions. The result from the Sentinel is a higher efficiency, reduction in noise, greater accurate controllability, better speed control drawing less power and as a result giving a better overall system performance.

With the new regulations now taking effect, choosing a LoWatt DC or EC fan that adheres to these requirements can be difficult and sometimes confusing. Taking this into account, Vent-Axia has developed its on-line fan selection programme, which can aid this difficult process. The on-line fan selection allows designers and specifiers to choose the right fan for the right application. To take advantage of Vent-Axia?s on-line fan selection process or for information on Vent-Axia?s range of energy efficient solutions visit www.vent-axia.com