Category Archives: Construction

Condair achieves workplace wellbeing charter

Story

Condair plc has been accredited by the Workplace Wellbeing Charter, the national accreditation standard that recognises an organisation’s commitment to improving the lives of those who work there. Condair achieved the standard through initiatives such as the introduction of free staff health MOTs, subsidizing gym subscriptions, investing in sit-stand desks and appointing trained mental health first aiders.

Condair plc has been accredited by the Workplace Wellbeing Charter, the national accreditation standard that recognises an organisation’s commitment to improving the lives of those who work there. Condair achieved the standard through initiatives such as the introduction of free staff health MOTs, subsidizing gym subscriptions, investing in sit-stand desks and appointing trained mental health first aiders.

Condair plc, the UK’s leading humidification specialist, employs 75 people, located either at its headquarters in West Sussex, or remotely situated around the UK, across its nationwide sales and service teams.

Tim Scott, head of sales at Condair plc, comments, “Employees who are happy and healthy are more engaged and productive in the workplace. We are very proud to have obtained this important accreditation, as it objectively demonstrates our commitment to continually improving the happiness, health and wellbeing of our staff.

“Condair has been at the forefront of the UK’s humidity control for 37 years. The fact that over half our staff have been with us for at least 10 years, and many for much longer, is testament to the importance we place on employee wellbeing and happiness. This doesn’t just make our day-to-day working lives more enjoyable but has a direct impact on the business’ profits. It helps us retain talented individuals, builds the most experienced workforce in the marketplace and ensures we deliver the best possible service to our customers.”

As part of the Workplace Wellbeing Charter accreditation, Condair was independently reviewed by a consultant, against a set of eight topic areas. These topics ranged from leadership and absence management to physical activity and healthy eating. The objective is to assess the company’s level of commitment to creating a culture that values health and wellbeing.

Tim Scott continues, “As an organisation, we have always been proactive about creating a happy workplace, with regular social events playing an important part in building a cooperative and friendly team atmosphere. We also encourage staff to manage their own health through subsidizing gym subscriptions, promoting tax-free bike-to-work schemes, offering sit/stand desks, company bikes for staff use, free bi-annual health MOTs and offering medical cash plans, which allow staff access to cheaper healthcare services for things like dental, optometry or podiatry.

“Alongside these investments, we also provide services to employees such as workshops on stress management, healthy eating and mindfulness, give staff support to stop smoking and allow time-shifting in working hours. Simply starting and finishing a working day at a slightly different time can improve a person’s work life balance and alleviate stress.

“Mental health has also been a focus for us in recent years. As well as internally promoting government initiatives like Mental Health Awareness Week, we have appointed and trained two mental health first aiders. These individuals are able to offer direct and confidential support to people who need it. As well as this one-to-one support, employees also have access to a confidential helpline, with experts who can provide advice on a range of topics from bereavement and debt to health and relationships.” Tim concludes.

The Condair Group is the world’s leading specialist in humidification and evaporative cooling, with energy efficient, hygienic and innovative technologies for commercial, industrial and heritage applications. Condair is represented in the UK by Condair plc, which offers system design, manufacture, supply, installation, commissioning, maintenance and spares.

View Condair's profile:

Planners back Marshall-Tufflex GRP trunking solution for iconic Brighton hotel

Story

An aggressive coastal location coupled with conservation regulations were key challenges for contractors tasked with installing a new air conditioning system at Brighton’s historic Grand hotel.

An aggressive coastal location coupled with conservation regulations were key challenges for contractors tasked with installing a new air conditioning system at Brighton’s historic Grand hotel.

Marshall-Tufflex’s Glass Reinforced Polyester (GRP) cable management system fitted the bill perfectly thanks to its corrosion-resistance, long-lasting durability and a heritage sensitive ‘sand colour that perfectly complemented the building’s Victorian facade.

More than 320m of perforated GRP tray with standard covers was installed on the rear of the seafront hotel to hold air conditioning pipes and cables to service all 201 bedrooms. This ambitious project was part of an on-going multi-million pound investment programme following the Grand’s sale to independent owners in 2014.

Paul Smith, of air conditioning contractor Airtemp, based in St Leonards-on-Sea, explained why GRP cable containment was the ideal solution: “We could not use metal due to the hotel’s position on the seafront, so the GRP provided a robust and saline-resistant solution. The sandy colour of the Marshall-Tufflex product also fitted perfectly with the back of the building and was recommended by planners.

“This was the first time we had used GRP trays but we modified the product to make it fit nicely and are pleased with the result. The system is of a very good quality and highly robust,” added Mr Smith.

“This was the first time we had used GRP trays but we modified the product to make it fit nicely and are pleased with the result. The system is of a very good quality and highly robust,” added Mr Smith.

GRP, particularly in locations exposed to extreme weather conditions and high salinity, is the perfect alternative to steel cable management. It is a corrosion-resistant, robust product specifically designed for challenging environments. It is also 40% lighter than steel, making it easier to move around site and fix, another plus point for this project given that The Grand wanted to minimise the impact of renovations on guests so ease of installation was crucial; the Marshall-Tufflex GRP trays require fewer fasteners and benefit from interlocking and self-adjusting couplings making it quick and easy to fit on site and modify without the need for special tools or earth bonding. Additionally, it has excellent fire safety credentials as GRP is a low conductivity, self-extinguishing material that is fully compliant with fire standards and regulations.

The GRP trays were supplied by Phase Electrical, Hastings.

A spokesman for The Grand Brighton said: “Following feedback from our guests we made the decision to install air conditioning throughout our 201 bedrooms. The project was uniquely challenging considering the infrastructure and heritage requirements of working on a Victorian era building so it was essential that we sourced the best contractor and products that would cause minimal disruption to our guests.

“We selected Marshall-Tufflex based on its top quality products and its established reputation. We are delighted with the results so far and the company went above and beyond to deliver the highest standard of customer service.”

“We selected Marshall-Tufflex based on its top quality products and its established reputation. We are delighted with the results so far and the company went above and beyond to deliver the highest standard of customer service.”

View Marshall-Tufflex's profile:

CONDAIR AT DATA CENTRE WORLD 2019

Story

Condair is appearing at the forthcoming Data Centre World exhibition on stand D921, at the Excel Centre in London from 12th to 13th March. The company will be displaying the latest in adiabatic and steam humidifier technology, which provides in-duct evaporative cooling and humidification to data centres.

Condair is appearing at the forthcoming Data Centre World exhibition on stand D921, at the Excel Centre in London from 12th to 13th March. The company will be displaying the latest in adiabatic and steam humidifier technology, which provides in-duct evaporative cooling and humidification to data centres.

Condair has extensive experience in working with data centre designers and air handling unit manufacturers that need to incorporate evaporative coolers or humidifiers into their systems. Previous data centre projects have involved clients such as Facebook, Microsoft, Digital Realty, Hewlett Packard, Amazon and eBay.

Condair’s experts will be on-hand at Data Centre World to give advice on how the latest humidifier technology can reduce data centre operating costs through improved energy consumption and reduced maintenance requirements.

Products on display include the Condair ME evaporative humidifier that offers 0.68kW of adiabatic cooling to an air handling system for every 1kg of moisture evaporated into the air stream. As the humidifier can provide up to 1,440kg/hr of humidity while operating on less than 1kW, it presents significant benefits to data centres using free air cooling systems. The technology can be employed to deliver direct or indirect evaporative cooling to facilities in warmer climates or add massive amounts of low energy humidification to data centres using cold, dry outside air in cold climates.

Alongside its market-leading in-duct evaporative system, Condair will have the Condair RS resistive steam humidifier on its stand. The Condair RS offers steam humidification to data centres without the need to frequently replace boiling cylinders, as is the case with many on-board humidification systems supplied with CRAC units. The humidifier has a scale management system that allows lime scale that builds up in the boiling chamber to fall into a removable tank at the base of the unit. Routine scale removal can be carried out by in-house maintenance staff in minutes, saving costs on consumables and maintenance time.

The Condair Group is the world’s leading specialist in humidification and evaporative cooling, with energy efficient, hygienic and innovative technologies for commercial, industrial and heritage applications. Condair is represented in the UK by Condair plc, which offers system design, manufacture, supply, installation, commissioning, maintenance and spares.

View Condair's profile:

Armourcoat Acoustic ‘quiet zone’ at Surface Design Show

Story

Armourcoat created a ‘quiet zone’ on their stand at the Surface Design Show in February to highlight the benefits of their acoustic plaster system. The company also featured among the main stage speakers and presentation to the 2019 Surface Design Award winners.

Armourcoat created a ‘quiet zone’ on their stand at the Surface Design Show in February to highlight the benefits of their acoustic plaster system. The company also featured among the main stage speakers and presentation to the 2019 Surface Design Award winners.

The Surface Design Show, held at Islington’s Business Design Centre, is a must-attend annual trade event to source products, gain new insights and connect with innovative and exciting materials such as Armourcoat Acoustic.

The system comprises of a special mineral wool composite panel that is bonded onto the substrate and finished with a seamless layer, presenting an elegant marble-based plaster finish while allowing sound energy to pass through the surface.

The Armourcoat stand focused on creating a ‘quiet zone’ at the show using the new acoustic plaster system recently granted the Quiet Mark Award – the international mark of approval from the Noise Abatement Society Charitable Foundation. Through its pioneering acoustic tests, Quiet Mark awards its distinctive Purple Q Mark to products and services that show excellence in low-noise and high performance.

The Armourcoat stand focused on creating a ‘quiet zone’ at the show using the new acoustic plaster system recently granted the Quiet Mark Award – the international mark of approval from the Noise Abatement Society Charitable Foundation. Through its pioneering acoustic tests, Quiet Mark awards its distinctive Purple Q Mark to products and services that show excellence in low-noise and high performance.

Poppy Szkiler, founder and managing director of Quiet Mark shared seasoned insights as a third generation noise reduction campaigner on the main stage, discussing acoustic solutions for a noisy world.

Poppy Szkiler, founder and managing director of Quiet Mark shared seasoned insights as a third generation noise reduction campaigner on the main stage, discussing acoustic solutions for a noisy world.

Armourcoat were also delighted to support the 2019 Surface Design Awards, sponsoring the ‘Sustainability’ categories.

Armourcoat were also delighted to support the 2019 Surface Design Awards, sponsoring the ‘Sustainability’ categories.

View Armourcoat's profile:

TONY FLEMING APPOINTED CONDAIR’s NEW HEAD OF SALES CLUSTER NORTHERN EUROPE

Story

Humidification specialist, Condair, has appointed Tony Fleming as the Head of Sales Cluster Northern Europe. Tony takes on responsibility for the operations of Condair’s two sales and manufacturing facilities based in the UK and Denmark, as well as the Condair sales offices in Ireland and Sweden.

Tony Fleming comments, “I am delighted to take on this new role of developing Condair’s operations in the key markets of the UK, Ireland and Scandinavia. The Condair Group has made significant investment in these regions as part of its recent global expansion and has seen good growth in all fields of humidification, evaporative cooling and dehumidification.”

Tony’s appointment follows a restructuring of Condair’s regional operations and the association of the UK and Ireland with Scandinavia as “Sales Cluster Northern Europe”. Tony’s previous position at Condair was Technical & Operations Director at Condair plc, for which he was and continues to be based in the Condair office in West Sussex, UK. Alongside his role at Condair, Tony also serves as a Non-Executive Director on the board of BSRIA.

All positions within Condair’s regional operations remain unchanged, including Tim Scott remaining as Sales Director for Condair in the UK and Ireland.

The Condair Group is the world’s leading specialist in humidity control and evaporative cooling, with energy efficient, hygienic and innovative technologies for commercial, industrial and heritage applications.

View Condair's profile:

Sterling data solution for football club’s state-of-the-art media centre

Story

A vast amount of data cabling is required to keep Swansea City Football Club’s media centre running smoothly – and Marshall-Tufflex’s Sterling Curve and Sterling XL PVC-U trunking have provided the perfect cable management solutions.

The club plays in the English Football League Championship and its media centre is regularly used by news and media agencies, such as Sky Sports, for outside broadcasts, interviews and press conferences.

The large amount of cabling required to service the centre is now managed via Marshall-Tufflex’s trunking fitted across four media rooms, which form part of the club’s new Fairwood training base. The state-of-the-art facility was built in collaboration with Swansea University at a cost of £10.5million.

Sterling Curve perimeter trunking is a three compartment, sleek, data compliant trunking with one or two curved data compartments. It has been specially designed to stop clutter, prevent dust traps and be easily cleaned. It is also easy and cost effective to install and incorporates a 25mm bend radius that allows it to be manipulated around corners for a sleek finish.

Accompanying this, Sterling XL trunking was chosen for its large capacity provided by deep, four-part compartments that can be segregated and added too. The system can be fed from larger trunking systems for increased cable distribution.

Both cable management solutions were supplied by Electrical Wholesale Supplies (Swansea) Ltd and designed and installed By EmC Services electrical contractors based in Carmarthen, Wales. Each is suitable for dado and skirting application and have power boxes available to comply with Part M/DDA requirements for visual impairment. They are available in white or charcoal as standard, are compliant up to Cat 7a and include adjustable data boxes that can be screened to help against electromagnetic interference.

This is the first time Swansea City FC has had its own training facility, previously using different local pitches and sports clubs. The Fairwood training base is predominantly used by the first team and has cutting-edge facilities that, alongside football pitches, include a high tech gym, altitude chamber, hydrotherapy pool, treatment rooms, large kit room and social areas.

View Marshall-Tufflex's profile:

Low surface temperature radiator series sees new additions

Story

Low surface temperature radiators – known as LSTs – are increasingly being specified for buildings used by vulnerable people where safe heat is required – for either the young or the elderly. The leading supplier of LST radiators in the UK is Stelrad and the company has recently released two new additions to its already extensive range by adding an LST Standard Deco and LST iPlus Deco design. They both feature its popular Deco horizontal lined fascia to the casings.

Low surface temperature radiators – known as LSTs – are increasingly being specified for buildings used by vulnerable people where safe heat is required – for either the young or the elderly. The leading supplier of LST radiators in the UK is Stelrad and the company has recently released two new additions to its already extensive range by adding an LST Standard Deco and LST iPlus Deco design. They both feature its popular Deco horizontal lined fascia to the casings.

LSTs are clearly the safe solution in hospitals, care and nursing homes, doctors and dentists’ surgeries and in universities, colleges, schools and nurseries.

The addition of the Deco fascias is a response to demand from customers to have a ‘designer look’ version of these popular but functional radiators and Stelrad has been happy to respond to this.

LSTs comply with the strict requirements of the NHS Guidance Note for ‘Safe hot water and surface temperature’ and can be installed in commercial and public buildings with total public safety assured. The surface temperature of these LSTs will never exceed 43°C.

For more details, head for www.stelrad.com.

View Stelrad's profile:

Take a Closer Look at Small Circulators

Story

It’s thought that there are still many millions of old, uncontrolled small circulators operating in heating systems across the UK, and they are using far more energy than they need to.

Especially now that leading pump manufacturer Wilo now offers the new generation of the Wilo-Yonos PICO series small circulators to the UK market. There’s a range of new features that have been added to this popular circulator, targeted primarily at residential homes and properties, for both heating systems and air conditioning equipment.

With this new version, Wilo has succeeded in not only upgrading one of the most established products in the market, but also to an extent, it has been able to reinvent it thanks to new functions built in to it and its ease of use.

With this new version, Wilo has succeeded in not only upgrading one of the most established products in the market, but also to an extent, it has been able to reinvent it thanks to new functions built in to it and its ease of use.

Together with these new functions, the compactness of Wilo-Yonos PICO has been dramatically improved to make it even easier to install and make maintenance far easier for the installer.

For more information on the Yonos PICO and the other small pumps in the energy efficient Wilo family of circulators, head for www.wilo.co.uk.

View Wilo's profile:

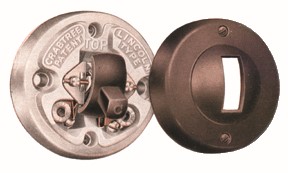

Crabtree: 1919 to 2019 and Beyond

Story

One hundred years ago John Ashworth Crabtree designed and patented a quick make and quick break switch. This innovation, which safely managed electric arcs that can occur in switching devices, was the beginning of the philosophy that became the culture of electrical safety for Crabtree.

One hundred years later and Crabtree remain at the forefront of electrical safety, this time with digital technology in Arc Fault Detection Devices. Crabtree AFDDs automatically detect and disconnect arc faults and prevent fires occurring in electrical cables and final circuits, providing higher levels of safety for homes and workplaces.

A lot can change in 100 years. Technology develops, new challenges emerge, solutions are found. But despite it all, the earth continues to turn, and those with a passion continue to design and innovate.

For a business that has weathered the storms of time, changed ownership, evolved its working methods and undoubtedly over 100 years, engaged many staff; one thing hasn’t changed, and that is the drive for new product development – a vital ingredient in the success of the brand.

We’re now on the 18th Edition of the Wiring Regulations, but back when the 12th Edition of the wiring regulations was just being published in 1950, Crabtree had been operating for over 30 years. It had launched during that time a number of innovations, including one still used today – British standard 13A twin sockets. Now a staple in homes and businesses across the UK, British standard 13A twin sockets first introduced by Crabtree in 1947.

In 1956, Crabtree introduced its first earth leakage circuit breaker, the voltage operated E.60 range. Earth leakage circuit breakers (or RCDs as we now know them) are standard products these days, but they were new in the 1950s when Crabtree developed this technology for devices that protect people from risks of electric shock. Fast forward 60-odd years to the very latest earth leakage devices and you will find innovative “A Class” Miniature RCBOs that include two-pole switching as standard for even higher levels of  personal protection.

personal protection.

Mike Cash, Group Marketing & Channel Manager at Electrium commented: “When Crabtree launched, we had a motto: That which is built soundly endures well. It was inscribed onto the company plaque and rightly so. Crabtree was built soundly enough to provide 100 years of electrical safety for our customers. And with a 100-year solid foundation what else can we do in the years to come?”

For more information go to www.electrium.co.uk/crabtree

View Crabtree's profile:

Condair Humidifiers At The National Army Museum

Story

Condair has recently supplied and installed three Condair RS resistive steam humidifiers to maintain the humidity around the exhibits and archives at the National Army Museum in Chelsea, London.

Condair has recently supplied and installed three Condair RS resistive steam humidifiers to maintain the humidity around the exhibits and archives at the National Army Museum in Chelsea, London.

Optimum environmental conditions are required to ensure the perfect preservation of military artefacts that are made of a wide range of materials, some of which date back to the English Civil War.

Mike O’Connor, Deputy Director at the National Army Museum, commented, “Precise climate control in our galleries and stored collections, across both temperature and humidity, plays an important role in preserving the nation’s military heritage. Our collections include an array of exhibits, from the cloak Wellington wore at Waterloo and Lawrence of Arabia’s dagger to modern day grenade launchers and drones. Metals, textiles, wooden objects and paintings can all be affected by high or low humidity, so a stable environment ensures longevity and avoids costly restoration work.”

The three Condair humidification systems were installed in weatherproof enclosures on the roof of the museum as part of its recent £24M refurbishment project. As well as resisting the London weather, the Condair enclosures incorporate a heater and fan unit to ensure the internal conditions remain within the humidifier’s recommended operating range. So, just as the humidifiers help the museum preserve its exhibits, likewise the enclosures do the same job for the humidifiers.

The Condair RS resistive steam humidifier is the ideal choice for heritage applications due to its responsive control and innovative scale management system. It can operate on mains water, as it is at the National Army Museum, and provide ±3%RH control, or on RO water and offer a close ±1%RH control. A humidifier that gives rapid response and close humidity control is important for museums that can be empty one minute and full of tourists in from the rain the next.

A patented scale management system on the Condair RS allows in-house maintenance teams to undertake routine scale removal, safely and quickly, without even needing to open the humidifier’s main cabinet. A scale collector tank is located under the boiling chamber, into which scale falls during operation. Scale removal is a simple process of draining the unit with the push of a button, disconnecting the cooled collector tank and emptying it.

The National Army Museum is the leading authority on the British Army and its impact on society past and present. It displays thousands of pieces across five themed galleries with a special temporary exhibition gallery, event space, a café and children’s area, Play Base. Admission is free to the permanent galleries and the Museum is open to the public between 10am and 5.30pm, daily.

The Condair Group is the world’s leading specialist in humidity control and evaporative cooling, with energy efficient, hygienic and innovative technologies for commercial, industrial and heritage applications. Condair is represented in the UK by Condair plc, which offers system design, manufacture, supply, installation, commissioning, maintenance and spares. You can find out more by visiting the company’s website at www.condair.co.uk.