Category Archives: Construction

Bona introduces wood floor styling at Clerkenwell

Story

As a showroom partner, wood floor specialist, Bona, through twice daily talks, will introduce the Clerkenwell community to its new ‘Inspiration’ wood floor styles, designed to transform the look of tired, existing wood floors or to embellish unfinished new ones.

As a showroom partner, wood floor specialist, Bona, through twice daily talks, will introduce the Clerkenwell community to its new ‘Inspiration’ wood floor styles, designed to transform the look of tired, existing wood floors or to embellish unfinished new ones.

Created by Bona in collaboration with internationally recognised trend analyst, Cay Bond, each of the 17 new looks can be achieved using a combination of Bona’s sanding and brushing methods to enhance the grain, followed by treatments with the company’s waterborne lacquers, oils and colours. The styles, Nordic Shimmer, Garden Atmosphere, Malibu Dreams, Touch of Grace and New Modern, include everything from dark, rustic floors to floors with a pale, lacquered finish.

Floor owners are often simply not aware of how an existing wood floor can be transformed, giving a room or space a completely new look and feel. From a sustainability perspective it makes sense too – the old floor has already been manufactured and transported.

A campaign starts on June 1st using social media, print and online advertising to target and inspire floor owners. Contractors will be able to use the professional pages at bona.com to see how the individual looks can be achieved, and samples and beautiful inspirational brochures will also be available for designers, architects and flooring contractors to leave with their clients.

Register for twice daily showroom talks entitled ‘Inspiration through renovation – how to achieve contemporary trends on existing wood floors’ at this link – https://www.bona.com/en-GB/Professional/Support/Events/Clerkenwell-Design-Week/ or via Bona’s Showroom page at clerkenwelldesignweek.com

View Bona's profile:

Expansion into advanced composites brings third Queen’s Award for Ancon

Story

Structural fixings manufacturer, Ancon, has won a 2018 Queen’s Award for Enterprise in the Innovation category, for the successful introduction and on-going development of its advanced composite, low thermal conductivity, Teplo wall tie range.

This is the third time that Ancon has been honoured in this prestigious award scheme that rewards outstanding achievements by UK businesses; it follows Queen’s Awards for International Trade in 2015 and Innovation in 2012.

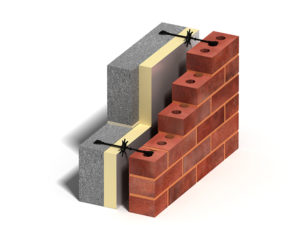

Teplo wall ties are manufactured from continuous basalt fibres set in a resin matrix; a fibre-reinforced polymer that is 70 times more thermally efficient than steel. When used to join the two leaves of a cavity wall, this material virtually eliminates cold bridging across the insulated cavity. Launched by Ancon in 2010 as part its market leading wall tie range, Teplo has had a major influence on the growth of low energy housing in the UK and Ireland, and helped future-proof traditional masonry cavity wall construction techniques, by minimising insulation thickness and wall footprint.

Whilst Ancon’s first Queen’s Award for Innovation in 2012 recognised the company’s in-house development of a unique lockable concrete-connecting steel component, this second Innovation award has been won jointly with its external strategic partner in this advanced composite development, MagmaTech.

Head of Marketing and Innovation at Ancon, Annabelle Wilson, says “Ancon launches a number of new and improved structural fixing solutions every year and invites ideas into our innovation process from both inside and outside the company. We saw potential in this new material immediately, and over the last eight years have committed our business resources to improving and extending the Teplo wall tie range as part of the Ancon product portfolio, bringing the benefits of advanced composites to mainstream UK construction.”

Today, the Teplo wall tie range includes Teplo-L suitable for surface-fixing in timber frame construction, the Teplo-BF with moulded safety ends that improve buildability particularly in lime and other slow-setting mortars, and the Teplo-BFR which can be resin-bonded in existing walls for retrofit applications. Teplo has been used in numerous ground-breaking developments, including the UK’s first masonry cavity wall ‘PassivHaus’, the UK’s first zero-carbon retrofit and the largest building in the UK built to the ‘Passivhaus’ standard, the University of Leicester’s Centre of Medicine.

Ben Williams, MagmaTech’s Managing Director says “Ancon has proven to be an exceptional partner for cutting edge innovation. They embraced a concept that was potentially disruptive to their existing stainless steel business, promoting it with passion and commitment. Taking a truly innovative energy-saving product to this level of market acceptance in just a few years is a truly outstanding achievement, surpassing our expectations.”

Commenting on their latest triumph in the Queen’s Award programme, Ancon’s Managing Director, Stuart Maxwell, says “Winning three Queen’s Awards in seven years is an extraordinary achievement and reflects the level of professionalism with which Ancon employees, in all areas of our organisation, go about their daily business. Our focus on quality and innovation, combined with a single-minded determination to excel in everything we do, not only underpins our brand reputation in the UK but its growing significance worldwide. It is another very proud day for everyone connected with Ancon and I thank our employees – both home and abroad – our customers and our suppliers for their continued support.”

Later this year the Lord Lieutenant of South Yorkshire will visit Ancon’s head office and main manufacturing site in Sheffield and officially present the 2018 award on behalf of HM The Queen. Ancon representatives will also attend a royal reception at Buckingham Palace this summer, hosted by HRH the Prince of Wales and other senior members of the Royal household.

Later this year the Lord Lieutenant of South Yorkshire will visit Ancon’s head office and main manufacturing site in Sheffield and officially present the 2018 award on behalf of HM The Queen. Ancon representatives will also attend a royal reception at Buckingham Palace this summer, hosted by HRH the Prince of Wales and other senior members of the Royal household.

View Ancon's profile:

Saniflo Kineduo walk-in shower-bath offers new features

Story

Sanifo – a leading designer and manufacturer of pumps, macerators, shower cubicles, shower trays and inclusively designed bathroom products – has added several new features to its walk-in shower-bath, the Kineduo, making it completely customisable.

Now with the option to choose the brassware and shower, the Kineduo is an ideal choice for versatile, modern living. Select between a T-bar shower or classic model. The overhead rainshower comes complete with taps and water filler.

Also new, are the round overflow filler, which can be purchased separately; an 800mm glass end screen panel added to the offering of the existing 750mm panel; and, a new soft close seat available from June this year.

Kineduo’s practical features include a simple step-in access using a hinged, toughened safety glass door and the bath is available in a variety of sizes and fit options.

Made from fully encapsulated acrylic, Kineduo is extremely robust and long lasting and has a clever adjustable feet system to add stability. Kineduo is available in both right and left-hand versions and with front and end panel colour options, making it suitable for most bathrooms and users.

As standard, the Kineduo comes with a cushioned headrest, a pop-up plug and a toughened safety glass door. The optional extras are then selected to personalise each customer’s Kineduo walk-in shower-bath.

Ann Boardman, Saniflo UK Head of Marketing and Product Development, comments: “With the new additions to the Kineduo bath, the experts at Saniflo have come up with something that is perfectly suited to all styles of living.

“The Kineduo is contemporary and designed to provide stylish, safe bathing for all household members. We are sure that the new Kineduo with its attractive features and completely customisable options will appeal greatly to the less and the more abled, as well as to the oldest and the youngest.”

View Kinedo's profile:

The Minster Building

Story

Armourcoat surface finishes have played a central role in the comprehensive refurbishment of the iconic Minster Building in the heart of London’s business district.

The interior design, by architects BuckleyGrayYeoman for Ivanhoé Cambridge and its development/asset manager Greycoat Real Estate LLP, has created a major repositioning of the building built around the central eight-storey atrium. The ground floor reception is approached by a 30 metre long boulevard from the new entrance on the corner of Mincing Lane and Great Tower Street. The original entrance has also been retained to Minster Court piazza.

Measuring seven metres high and up to eight metres wide, the impressive entrance boulevard has a polished floor of terrazzo with bronze inlays, edged by dark oak. Throughout the entrance and reception spaces, the walls are hand-finished in nearly 2,000m2 of Armourcoat polished plaster together with over 600m2 of the company’s Acoustic Plaster System applied to the ceilings.

Designed to optimize the acoustics of interior spaces, the Acoustic Plaster system offers a clean and smooth mineral surface that can be applied seamlessly over large expanses to both flat and curved surfaces. Comprising of a special mineral wool composite panel that is bonded onto the substrate and finished with a seamless layer, the Armourcoat Acoustic Plaster System offers an elegant marble based plaster finish while allowing sound energy to pass through the surface. The zero VOC system, which consists of 80% recycled material, achieves class ‘0’ fire rating and a class ‘A’ Noise Reduction Coefficient rating.

Photography: © Jonathan Banks

View Armourcoat's profile:

How REHAU Recycles

Story

Ever wondered how old PVC-U window frames are transformed into brand new ones? Well wonder no more as Richard Hardstaff, General Manager at PVCR, explains it all:

Q: How easy is it to recycle PVC?

A: PVC is very straightforward to recycle and can be mixed with virgin polymer to give it a whole new lease of life. PVC can be recycled up to 10 times.

Q: Can any recycled plastic be used to make new window frames?

A: The types of material we deal with at PVCR are best recycled into new versions of themselves – so old PVC windows are transformed into new ones, old water bottles are made into new water bottles etc.

Q: Which PVC window frames can be recycled?

A: Ideally we want good quality de-glazed window and door frames to ensure the recycled material is of a good standard. Laminated frames are also OK to recycle.

Q: What processes are involved in recycling PVC?

A: Firstly, the frames are broken down and put into a shredder to reduce the size of the material, and any metal is removed. Next, the material is put in water and essentially everything we want sinks. We then separate the material again using a vacuum to ensure any rubber or leftover metal is removed before it goes into the granulator.

The granulator reduces the material to 10mm in size, before its washed, dried and put through electrostatic separation to remove any remaining residue or organic material. Its then colour sorted before the clean, white PVC material is ready to send to REHAU’s factory in Wales.

Q: What is the PVC material used for in the manufacturing process?

A: After being cleaned and lab tested, the white PVC material is sent to REHAU’s factory in Blaenau, where it used to make TOTAL70 co-extruded profiles.

Q: Is there growing demand for recycled PVC?

A: We have seen a dramatic increase in demand and by 2019 our capacity will have doubled, if not tripled.

Q: What’s the reason behind this uplift in demand?

A: Consumer demand is the main driver. By using recycled plastic, businesses can meet the needs of eco-conscious customers, give their products a USP, and do their bit for the environment.

For more information and to see the process in action visit www.pvcr.co.uk

View Rehau's profile:

Large span windows and doors set new design standard

Story

Much has changed in relation to door and window technology over the past 20 years and this is reflected in the increasing popularity of features such as large span roof windows and bi-folding doors. Both are now used as an intrinsic element of interior design as they enable natural daylight to transform areas in which we live and work.

For walls, use of floor to ceiling glazing has enabled exteriors to be ‘brought into’ the living environment, capitalising on views provided and enhancing perceptions of space. Design engineers are now, however, able to maximise the functionality of timber and aluminium to produce far larger sash and frame profiles than ever before. This requires a level of precision beyond the capability of traditional manufacturing techniques while, in terms of design complexity, durability, security and thermal / acoustic performance all have been considerably improved.

The type of timber used for the weight of such windows and doors is critical so Fakro opted for pine, oak and meranti hard woods to provide a combination of high performance and a high visual aesthetic. They also provide long-term structural stability, a critical factor not just for the ability to withstand distortion but to retain energy efficiency and airtightness. This was the driving factor influencing design of the Innoview range, in which triple and quadruple-glazed construction is used with low emissivity glazing and a quadruple sealing system. With warm spacers between panes, the overall heat transfer coefficients in is as low as 0.68/W/m2K (with Ug values of 0.3W/m2K in quadruple-glazed units).

Designs in which windows of such a large span are specified inevitably necessitates manufacture of bespoke sizes for individual projects. In achieving the ability to do so, Fakro can now fulfil the same service it has been providing with roof windows for more than 20 years. This enables architects and interior designers to create homes and work places with a distinctive identity and character while also meeting specific technical aspects of performance.

With scope to specify colours from the RAL Classic Palette and use of close-grain timber from FSC-certified sources, the standard of internal finish immediately provides clear evocation of quality. Modern coating and lacquering techniques, matt or satin finishes and choice of sash profile enable the windows and doors to complement the most diverse interior design requirements. Appearance is enhanced by concealed hinges and invisible fixings while use of sliders in conjunction with a roller lifter and rotary cam ensure that positioning in the frame remains constant, regardless of usage intensity. Soft closure also slows the sash movement prior to positioning it in the frame. Such ease of operation has been described as ‘out of all proportion to what might be expected from windows of such a size’.

EPDM rather than silicone seals are used as they provide far greater long-term reliability through their shrinkage resistance and bond between glazing and frame. This not only gives far greater assurance of air and weathertightness but provides a greatly improved standard of finishing. Windows and doors have anti-burglary, multi-point locks and Class RC1 or RC2 glazing units (the latter optional extra providing nine locking points per window). The hardware also has sufficient strength to provide a load capacity of up to 150kg in standard door and window sizes.

Fixed, arc and multi-sash windows with movable or structural mullion bar, balcony doors with a low aluminium threshold and tilt or lift and slide doors are available. Widths of up to 12 metres and heights up to 2.8 metres as well as non-standard shapes can be accommodated with single or double sash lift and slide doors up to a weight of up to 400 kg.

In terms of design innovation considerable attention has also been paid to external appearance with powder-coated aluminium outer cladding providing a combination of high performance and lasting appearance. The potential to specify the required colour and absence of visible welds at corners provides seamless, contemporary styling.

Products such as Innoview HST doors have virtually no visible while PSK tilt and slide doors provide scope for micro-opening to provide room ventilation without reducing the level of security. Such developments can only provide further incentive to change the face of contemporary fenestration while providing scope to do so in designs up to Passivhaus standard.

View Fakro's profile:

Twenty Old Bailey

Story

Armourcoat polished plaster wall finishes feature within the major office refurbishment of Twenty Old Bailey by architects BuckleyGrayYeoman for global asset manager Blackstone.

Located opposite the famous criminal courts in the city of London, the building has undergone a comprehensive modernisation programme to create over 22,000m2 of contemporary office space. A reconfigured atrium has also been created, which links the new facades to the East and West of the building, and allows natural light to flood the interior.

Throughout the atrium over 700m2 of Armourcoat ‘KonCrete’ polished plaster has been expertly hand-applied and includes a recessed logo by the entrance. ‘KonCrete’ is an urban range of polished plaster colours and finishes designed for contemporary projects. The range offers a wealth of design options to achieve a distinctive modern look including distressed effects or recessed shutter markings.

Additionally Armourcoat ‘SMG’ was applied to the reception desk front and lift lobbies. ‘SMG’ is a super luxury polished plaster finish with the appearance of a seamless high-gloss lacquer effect. It provides an opulent decorative effect offering great light reflection to create an inviting and spacious interior.

View Armourcoat's profile:

Saniflo helps turn London couple’s big dream of a ‘Grand Designs’ tiny house into reality

Story

Saniflo – the UK’s leading designer and manufacturer of pumps, macerators and shower cubicles – has helped make a big dream of a Grand Designs tiny house into a reality.

Saniflo – the UK’s leading designer and manufacturer of pumps, macerators and shower cubicles – has helped make a big dream of a Grand Designs tiny house into a reality.

Built and designed by 28-year-old design engineer Joe Stuart of Joe Stuart Industrial Design for him and his girlfriend to live in, the couple’s tiny house was featured on popular TV show Grand Designs earlier this year.

The 38m² plot required an innovative solution to maximise the space to convert it into a two bedroomed, two-bathroom property, which involved digging down to form a basement and building six half floors.

The first bathroom is gravity fed, whilst the second – originally designed as a laundry – sits half a floor down from street level and required a pump to take the waste to the discharge point.

The industrial design wetroom features a shower, basin and WC each feeding into a Saniflo Sanicubic Pro 2 macerating pump situated directly beneath the wall hung WC in the basement.

The pump will also take waste from a washing machine which will be sited in the basement and has additional outlets for the connection of future appliances.

The Sanicubic Pro 2 featuring dual motors, offers continuity of service, so if ever one fails then the other will assume the workload. The Saniflo pump enabled the couple to install a second bathroom which adds value to their home. The unit is plumbed into the basement and the couple were even able to install the pump themselves and say it was really simple and straightforward. Because of the multiple connection points, they will be able to plumb more appliances into the unit in future.

Saniflo UK Head of Marketing and Product Development, Ann Boardman, comments: “What Joe has achieved with the Grand Designs tiny house is incredible and whilst his design was workable without the Sanicubic, he was able to install that all-important second bathroom with it adding value to his home. It also enabled him to site his washing machine in the basement rather than elsewhere in the property. Domestic and commercial projects up and down the country rely on macerators and pumps to function, everything from prestigious London landmarks like The Shard, and tiny London landmarks like Joe’s home. Using macerators and pumps really expands the scope of what we can do with seemingly insurmountable projects.”

View Saniflo's profile:

Bona inspires with new concepts in floor trends

Story

The renowned Swedish company Bona is setting the trend in floor styling with ”Bona Inspiration”, a unique concept in designing fashionable floor styles. In collaboration with the internationally recognized trend analyst Cay Bond, their sight is now set on the floor as a crucial design detail.

Interior design and home decoration has long been influenced and inspired by trends, but floor renovation has been lagging one step behind. Bona wants to change that, and in collaboration with Cay Bond who has more than 30 years’ experience of trends within fashion, design and interiors, Bona has created an entirely new concept – to inspire and create on-trend styles and flooring effects.

Bona has been at the forefront of floor renovations and maintenance for a long time. This solid knowledge is now enhanced with inspiration and guidance in flooring trends to create the right ambience in the home.

– We have developed a concept which can create the right style and effect on a  wooden floor using our products and techniques. With the right treatment, you can preserve the soul of the floor while producing a whole new look without installing a new floor. With Bona’s extensive product range, you can make magic from an existing floor in only a few hours, says Patrik Mellnert, Product Manager at Bona.

wooden floor using our products and techniques. With the right treatment, you can preserve the soul of the floor while producing a whole new look without installing a new floor. With Bona’s extensive product range, you can make magic from an existing floor in only a few hours, says Patrik Mellnert, Product Manager at Bona.

The Bona Inspiration concept includes an inspiration palette encompassing a range of interior design styles in which the wooden floors play an important role, and Bona’s sanding and brushing methods, varnishes, oils and paints can bring new life to a wooden floor. The future trends presented by Bona in their unique concept includes everything from dark, rustic floors to floors with a pale, lacquered finish. To restyle old wooden floors is not only sustainable, it’s also beautiful and a trend of the future.

The concept will be launched in Europe, USA and Asia in 2018.

For further information, please contact:

Bona Senior Vice President Product Management and Marketing,

Björn Saalbach,

+46736557557

Bona Product Manager,

Patrik Mellnert,

+46 40 38 73

View Bona's profile:

Marshall-Tufflex GRP trunking keeps rail station renovations on track

Story

With more than 200 million passenger journeys a year, durability and ease of installation were key considerations for contractors leading a multi-million pound upgrade of a high profile UK rail station.

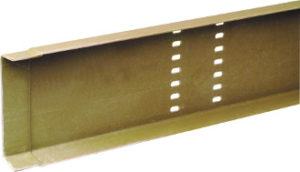

Rail projects have some of the most challenging cable management requirements due to the harsh, and sometimes hazardous, environment of their locations. With its lightweight construction, long life span and resistance to fire and corrosion, Marshall-Tufflex’s Glass Reinforced Polyester (GRP) cable management system provided the perfect solution.

More than 700m of perforated GRP tray with standard covers has helped deliver power and data provision for station signalling, lighting, tannoys and surveillance systems. The installation formed part of renovations to bring old platforms back into use and extend current platforms to accommodate longer trains.

GRP is the material of choice for a wide range of cable management projects in the rail network. The robust product is specifically designed for challenging environments with the material effective at temperatures from -80°C to over 130°C. It is both corrosion and fire resistant with low thermal conductivity and self-extinguishing properties that make it fully compliant with fire standards and regulations.

Weighing 40% less than steel it is also easier to move around and install. The trays require fewer fasteners and benefit from interlocking and self-adjusting couplings making them quick and easy to assemble and configure on site. The flexibility of the system helped save time and labour costs, both critical in ensuing platforms were reopened on time and within budget.

GRP tray is one of Marshall-Tufflex’s specialist product ranges for the rail industry and was supplied by Rexel’s Rail Division in Bermondsey, London. The product is registered with RISQS (Railway Industry Supplier Qualification Scheme) that supports Network Rail, Transport for London and UK train operators in the management of supply chain risk.