Category Archives: Construction

Free CPD Guide to energy labelling regulations

Story

Mitsubishi Electric has produced a free, CPD-accredited guide to the new Energy Related Products Directive or ErP (2009/125/EC), which is a key part of the European Union’s drive to encourage consumers to use more energy efficient products.

Mitsubishi Electric has produced a free, CPD-accredited guide to the new Energy Related Products Directive or ErP (2009/125/EC), which is a key part of the European Union’s drive to encourage consumers to use more energy efficient products.

The ErP Directive, which came into force at the end of September, now means that commercial and residential heating products will need to display an energy label, so that consumers can quickly understand the energy efficiency of the products they purchase.

A similar market transformation strategy has already proved highly successful with consumer goods such as fridges and freezers, where it is now very rare to find anything below an A rated product available on the high street.

To highlight the requirements under ErP Mitsubishi Electric has also released a short video which explains how the Directive is designed to help phase out lower performing products whilst having a positive impact on the emissions levels across Europe and increase the share of renewable energies by 20 per cent.

The dedicated video can be viewed at the company’s YouTube Channel and further information on the entire range of A++ heat pumps can be found on the dedicated Youtube channel at: https://www.youtube.com/watch?v=rk1ldYXNpuw&list=PLvcrLXkBScHpdC0WSvzpO3uvwawcNjpIr&index=10

The Directive is a two-part strategy. Firstly, the ErP requires manufacturers to produce energy-using products that meet stringent minimum performance standards. And secondly, these products must be clearly labelled using a standard methodology so that consumers can quickly understand the energy efficiency of the products they purchase.

The CPD Guide covers both main parts of the ErP: the EcoDesign regulations and the Energy Labelling regulations. The guide explains how the labelling is designed to help businesses and homeowners understand the benefits of each technology and focuses on the importance of ErP in relation to legislation such as the Renewable Heat Incentive (RHI).

For further information, visit http://bit.ly/1NBrWjl

Click on the images to enlarge

View Mitsubishi Electric's profile:

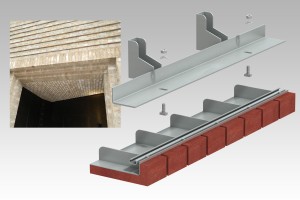

Making light work of brick soffits

Story

Creating flawless brick-faced soffits and lintels has now become much simpler and quicker, thanks to a new lightweight stainless steel based system developed by two industry-leading companies – brick support specialist Ancon Building Products and Ibstock Kevington –national manufacturer of brickwork and masonry special shapes and prefabricated components.

Creating flawless brick-faced soffits and lintels has now become much simpler and quicker, thanks to a new lightweight stainless steel based system developed by two industry-leading companies – brick support specialist Ancon Building Products and Ibstock Kevington –national manufacturer of brickwork and masonry special shapes and prefabricated components.

The new Nexus® system combines a specially developed Ibstock Kevington lightweight brick-faced steel unit with Ancon’s tried and tested MDC stainless steel bracket angle support system. The system offers contractors easier handling coupled with maximum adjustability, both vertically and horizontally, for quick and simple alignment on site.

The new system offers considerable benefits over traditional cast concrete alternatives – cutting weight by more than half, which in most cases will allow the brick-faced units to be installed without specialist lifting equipment, and significant savings in installation time – making it particularly appropriate for fast-track or time-limited projects.

Individual Nexus® units are designed and prefabricated off-site to suit different soffit dimensions, even modern deep soffits, so there is no cutting required on-site. They are simply offered up to the pre-fixed and pre-drilled Ancon MDC support system and then bolted into position using T-head bolts. The quality design allows units to be simply adjusted for perfect alignment and, once in position, all that is left is for the brick facing to be pointed for a seamless match with the main brickwork.

Nexus units can be fabricated using virtually any brick or masonry with the chosen product being specially selected and precision cut, generally from the same batch as the main façade to ensure a perfect visual match. Various brick patterns can also be specified to match individual project designs and styles.

All system components are of the highest quality, and engineered for economy and durability, with slips permanently bonded to the high grade stainless steel Nexus system using a BBA accredited bonding system. Nexus has been independently tested for long term durability by Lucideon, the independent global experts in materials testing, analysis and consultancy.

Ibstock Kevington Sales Director, Warren Dean said, “Nexus ® is an exciting new development that brings together the combined experience and expertise of two major companies – each market leaders in their own area. The advanced design will not only make it easier and quicker to specify and install modern brick-faced soffit and lintel features in a range of different building applications, but the two-part design means it will be far easier to achieve perfect alignment with the main brickwork façade.”

Further details and technical specifications for the Nexus® system are available in a new 4-page brochure, available to download from www.ancon.co.uk/Nexus.

View Ancon's profile:

Klober underlay for low pitch roofs

Story

A big problem when designing an extension is what to do where the roof pitch is limited by existing windows or pipework. Using a matching natural slate or clay / concrete plain tile has always been out of the question but Klober’s new underlay, Permo® extreme RS SK2 can be used at 12.5° with profiled tiles or 15° with flat tiles and slates.

A big problem when designing an extension is what to do where the roof pitch is limited by existing windows or pipework. Using a matching natural slate or clay / concrete plain tile has always been out of the question but Klober’s new underlay, Permo® extreme RS SK2 can be used at 12.5° with profiled tiles or 15° with flat tiles and slates.

This provides complete flexibility with tile selection and avoids the need to use unsightly, large format concrete tiles which just weren’t designed for small roofs. Permo extreme is tear-resistant and has double, self-adhesive strips which provide a permanent seal of laps. It provides immediate weather protection, water driven to the top of tiles being carried between the counter battens to the gutter. This is a job that standard vapour permeable underlay are not designed to do.

Permo extreme is best laid onto 12mm ply board or OSB sarking board. This makes sealing laps easy and avoids the need for care when determining drape between rafters. Standard counter battening is employed with ventilation at or near the ridge with cold roof construction. Klober Butylon tape must also be used beneath counter battens to seal around any nail penetrations.

View Klober's profile:

Sterling – the best just got better!

Story

One of the UK’s most popular cable management ranges has been updated to offer up to 15% more cable capacity, easier fitting and quicker, more secure installations that are even better looking.

One of the UK’s most popular cable management ranges has been updated to offer up to 15% more cable capacity, easier fitting and quicker, more secure installations that are even better looking.

The Sterling range by market-leader Marshall-Tufflex has been one of the market’s best selling trunking solutions for almost 25 years, with Sterling Profile 1 being the star performer of the range. To increase its appeal further Marshall-Tufflex designers have introduced a number of changes to the range:

- Improved base design for greater cable capacity

- New pre-punched knock-outs in the dividing wall, a time saving benefit for installers

- New single-piece moulded fittings for Profile 1 (coupler, end cap, internal and external bends)

- New moulded covers for Profile 1 flat tees and flat angles for easier installation and improved aesthetics

- More secure fittings due to improved clipping action

- Dividing fillets and cable retainers clip on more easily

- An improved RCD housing that clips directly to the central compartment of the Sterling base making installation much faster.

- A new faster to install RCD/MCB housing

The new streamlined base is compatible with existing Sterling fittings. However, the newly designed fittings are only compatible with the new base, the old base will be phased out over the next few weeks. Marshall-Tufflex has prepared a product compatibility sheet for wholesalers to enable them to assist customers with correct product selection and a product compatibility sheet for contractors, available from www.marshall-tufflex.com

The new, updated Sterling range is covered in detail in Marshall-Tufflex’s new Cable Management Catalogue. For a copy visit www.newcatalogue.co.uk, e-mail sales@marshall-tufflex.com or telephone +44 (0) 1424 856600.

View Marshall-Tufflex's profile:

Ohmmeter tests transformers faster and safer

Story

MTO250 series ohmmeters are readily portable mains powered instruments that have been specifically designed to accurately measure the resistance of all types of magnetic windings. Typical applications include the testing not only of transformers, but also of shunt reactors and the windings of rotating machines. In addition, MTO250 test sets can be used for performing many other types of low resistance measurements.

MTO250 series ohmmeters are readily portable mains powered instruments that have been specifically designed to accurately measure the resistance of all types of magnetic windings. Typical applications include the testing not only of transformers, but also of shunt reactors and the windings of rotating machines. In addition, MTO250 test sets can be used for performing many other types of low resistance measurements.

Validation of correct make-before-break operation of load tap changers is also supported and when this type of test is carried out, the instrument continually monitors transition currents, with high resolution, for each tap position, so that even slight discontinuities are detected and reported.

These innovative instruments support the use of test currents up to 50A, a feature which reduces the time needed to test high-current secondary windings by as much as ten times compared with standard instruments that have a maximum test current capability of 10A. When the tests are completed, an integrated demagnetisation feature ensures that the transformer can be returned to service without risk of excessive inrush current or other problems associated with core magnetisation.

Among the many safety features built into the MTO250 as standard is an auto-discharge function that operates when the test is completed, in the event of power loss or if a test lead is inadvertently disconnected. A safety interlock circuit is also provided, together with provision for the connection of a strobe beacon to provide a visual warning that a test is underway.

Internal data storage for test results is a standard feature, and the test sets can optionally be connected to a PC running Megger’s PowerDB software to provide full automatic control.

To complement the new MTO250 transformer ohmmeters universal Kelvin clamps with 100 mm adjustable jaws are available. These eliminate the need for multiple types of lead clips. Each Kelvin clamp also includes banana plugs for use on external probes for testing on terminal blocks.

To find out more click here

View Megger's profile:

The reinvention of large electrofusion couplers for quick and reliable connections

Story

Constructing large dimension pipelines is challenging and requires specific designs of the pipeline components. The GF Piping Systems electrofusion couplers for water and gas applications are therefore made for quick and reliable connection of your pipes and spigot fittings. Even under difficult site conditions the electrofusion couplers from GF Piping Systems provide a long lasting and safe connection thanks to the careful design.

Constructing large dimension pipelines is challenging and requires specific designs of the pipeline components. The GF Piping Systems electrofusion couplers for water and gas applications are therefore made for quick and reliable connection of your pipes and spigot fittings. Even under difficult site conditions the electrofusion couplers from GF Piping Systems provide a long lasting and safe connection thanks to the careful design.

Proven technologies

The electrofusion coupler product range of d355-d1200mm consists of two production technologies. Couplers with flex groove design (d900-d1200mm) ensuring a good jointing thanks to the special geometry and wall thickness.  Dimensions from d355 to d800mm are provided with the proven technology of active reinforcement (pipe in pipe).

Dimensions from d355 to d800mm are provided with the proven technology of active reinforcement (pipe in pipe).

Your benefits

- The extra-large inner diameter of the coupler permits easy assembly and can accommodate pipe ovality often found in practice.

- The smooth fusion zone (covered heating wires) guarantees an ideal fusion result.

- Reduced installation time without pre-heating or use of additional equipment.

- On path-limited fusion indicator each per fusion zone for immediate check.

- No special welding machine required, all current GF welding machines are suitable

- QR-code on each label links you directly to a dedicated web page enabling the online access of instruction videos and technical documentation.

View Georg Fischer's profile:

Second Queen’s Award presentation in three years for Ancon

Story

Just three years after its first Queen’s Award for Enterprise presentation in 2012, Ancon Building Products officially received its second award on Thursday 15th October at a special ceremony at its manufacturing site in Deeside, North Wales.

Just three years after its first Queen’s Award for Enterprise presentation in 2012, Ancon Building Products officially received its second award on Thursday 15th October at a special ceremony at its manufacturing site in Deeside, North Wales.

The 2015 Award, for International Trade, recognises Ancon’s outstanding success in growing sales across new and existing export markets. It follows the company’s previous Queen’s Award for Enterprise in Innovation for its ground-breaking Lockable Dowel, a system that has since revolutionised post-tensioned concrete construction.

The prestigious award, the highest accolade that any UK business can achieve for export growth, was presented to Ancon by the Lord Lieutenant of Clwyd, Mr Henry George Fetherstonhaugh OBE, on behalf of Her Majesty the Queen.

The ceremony at the Deeside facility, the largest and most advanced Wall Tie manufacturing operation in the UK, was attended by 36 employees who proudly watched Ancon’s Export Team Leader, Angela Reeve, accept the ceremonial scroll from the Lord Lieutenant. Her colleague Lynn Forster, Deeside’s Purchasing Manager and longest-serving employee at the site, who has been part of the Ancon team there for the last 32 years, received the commemorative Queen’s Award crystal bowl on behalf of the company.

The Lord Lieutenant said,

“Ancon represents the very best of British innovation and technology, and this dynamic company, which has trebled its exports in the last ten years, has led the way in its field.”

“To win one award is pretty spectacular; to win two awards in three years is absolutely amazing.”

“It is very gratifying to present this award here in Deeside, where Ancon provides 92 much needed jobs and I wish the company every continued success in the future.”

In addition to its headquarters and two manufacturing sites in Sheffield, South Yorkshire, Ancon has operated production facilities in North Wales since 1983. The Lord Lieutenant met several employees as he toured the site on Deeside Industrial Park, where the company has been based since 2008 when they outgrew previous sites in Flint and Greenfield.

Speaking after the ceremony, Managing Director, Stuart Maxwell said,

“It’s another very proud day for the Ancon business. We now hold Queen’s Awards for both Innovation and International Trade, confirming that we are successfully combining the development of market-specific solutions with effective worldwide distribution strategies. Our UK-manufactured products are now exported across the globe from the USA, Russia, throughout the far east and into the Asian pacific regions.”

“Our outstanding achievements over the last few years are down to the knowledge, hard work and commitment of our employees, as well as our distributors around the world. My sincere thanks and congratulations go out to everyone.”

“With a number of major construction projects and new product launches in the pipeline, I am certain the business will continue to go from strength-to strength.”

View Ancon's profile:

Timbmet helps put vintage rollercoaster back on track

Story

Timbmet, one of the UK’s largest distributors of timber and timber products, has played a major role in the restoration of the nation’s oldest rollercoaster, the Scenic Railway in Margate, Kent. The Grade II listed timber-framed ride which is now open is the focal point of the revamped Dreamland funfair.

Timbmet, one of the UK’s largest distributors of timber and timber products, has played a major role in the restoration of the nation’s oldest rollercoaster, the Scenic Railway in Margate, Kent. The Grade II listed timber-framed ride which is now open is the focal point of the revamped Dreamland funfair.

The ride is the first ever to be listed by English Heritage and one of just eight scenic railways in the world.

The park, which originally opened in 1920, has been the subject of an £18 million refurbishment which began in September 2014 after Thanet Council bought the funfair the year before. A traditional amusement park, Dreamland had been popular with local residents and seaside day-trippers for generations. However, following its closure 10 years ago, the site fell into disrepair while campaigners fought, with eventual success, to save the land from development.

During that time, the historic Scenic Railway was also the victim of an arson attack in 2008 which has made its restoration even more challenging: about 25% of the structure, the station and storage sheds were destroyed, along with the train car bodies.

The restoration of Dreamland is an integral part of the ongoing regeneration of Margate. Grants from Thanet Council and the Heritage Lottery Fund have contributed to the work, while in 2009, the Dreamland Trust was awarded a grant from the UK Department for Culture, Media and Sport to restore the Scenic Railway and to rejuvenate the Dreamland site.

Timbmet: up for the challenge

For this project, Timbmet worked closely with Doncaster-based WGH Engineering Ltd, the company contracted to rebuild the two trains of three carriages each, with each carriage accommodating up to 28 passengers.

Originally, WGH designed and built vehicles and locomotives for use on narrow gauge underground tracks for the mining industry. After the 1984 miner’s strike, the company sought a new outlet for its skills in designing equipment to run on difficult and challenging tracks. Today, WGH designs and builds various types of leisure rides, including rollercoasters and log flumes, as well as suspended and ground-mounted track rides.

The Scenic Railway project presented a unique challenge for WGH, which usually works with aluminium and steel. “As this was the first time our company had worked with timber,” explains WGH Director, Tony Brown, “we approached Timbmet for advice and assistance in sourcing the appropriate material that would not only maintain the spirit of the original 1920s design, but also meet current legislation and satisfy modern-day requirements.”

As a traditional, family-owned company with over 70 years in the timber business, Timbmet was well poised to take up such a unique challenge. Like Dreamland and WGH, Timbmet is steeped in history and heritage, and given its years of experience and teams of timber experts, is well qualified to source specialist timber for specific projects such as Dreamland.

For the Scenic Railway’s carriages, Timbmet supplied WGH with constructional grade Opepe hardwood, as John Dodman, Timbmet’s Northern Business Manager, explains: “The objective was to replace the people bogeys with material used when the rollercoaster was originally built back in 1920. Opepe African hardwood was specified as it is very durable and strong and has the load-bearing capacity necessary for this specialist restoration.

John continues. “The Timbmet team was able to supply Opepe hardwood cut to the sizes and lengths requested. This saved our customer time, made the timber easier to use, and had minimal waste.”

A dream partnership

“Opepe has proved ideal for this usage,” John Dodman concludes, “For Timbmet and WGH, the restoration of Dreamland’s Scenic Railway was a unique project to be involved with and gave us a fantastic opportunity to use our Timber expertise to support the highly significant venture for the Margate area and English Heritage.”

View Timbmet's profile:

Low roofline installation from FAKRO proves the perfect window option

Story

Dualchas Architects’ design of Taigh Learaige in Stanley, Perthshire shows the benefit of being able to install FAKRO roof windows at varying depths. The visual aesthetic is greatly enhanced by their low profile in a structure which takes the timber from the roof into the walls with no visible rainwater goods. Eight non-vented, triple-glazed FTV U5 centre pivot windows were used with thermal combination flashings and XDP fitted underfelt collars around each window. Architect Alasdair Stephen commented, “The Fakro windows were used because of the wide range of sizes and the scope the company offers for project-specific customisation. They are also great value compared to other glazing systems”.

Dualchas Architects’ design of Taigh Learaige in Stanley, Perthshire shows the benefit of being able to install FAKRO roof windows at varying depths. The visual aesthetic is greatly enhanced by their low profile in a structure which takes the timber from the roof into the walls with no visible rainwater goods. Eight non-vented, triple-glazed FTV U5 centre pivot windows were used with thermal combination flashings and XDP fitted underfelt collars around each window. Architect Alasdair Stephen commented, “The Fakro windows were used because of the wide range of sizes and the scope the company offers for project-specific customisation. They are also great value compared to other glazing systems”.

View Fakro's profile:

VMZINC compact roof for Wyre Forest Crematorium

Story

A standing seam roof in VMZINC QUARTZ-ZINC PLUS® has been used in Howl Associates’ design of Wyre Forest Crematorium in Kidderminster. It consists of a series of ‘floating’ roof forms separated from walls with frameless clerestory glazing. Acoustic considerations were a prime concern due to the proximity of an adjacent industrial estate, major road and rifle range. Zinc, with its Green Guide A rating and compact roof build-up, was selected to deal with the complex geometry of the main chapel and used alongside green roofs on the site maintenance building.

A standing seam roof in VMZINC QUARTZ-ZINC PLUS® has been used in Howl Associates’ design of Wyre Forest Crematorium in Kidderminster. It consists of a series of ‘floating’ roof forms separated from walls with frameless clerestory glazing. Acoustic considerations were a prime concern due to the proximity of an adjacent industrial estate, major road and rifle range. Zinc, with its Green Guide A rating and compact roof build-up, was selected to deal with the complex geometry of the main chapel and used alongside green roofs on the site maintenance building.