Category Archives: Energy

Ancon honoured at third Buckingham Palace Royal Reception

Story

Ancon has been honoured at a Royal reception to celebrate its success in the 2018 Queen’s Awards for Enterprise – the third Queen’s Award for the company.

The champagne reception, held in the State Rooms of Buckingham Palace, was hosted by HRH The Prince of Wales, on behalf of HM The Queen. Other members of the Royal Family, including HRH The Duke of Kent, were in attendance, underlining the status of this prestigious industry award.

Ancon’s Export Manager, Hervé Poveda, and Operations Director, Peter McDermott, represented Ancon at the event, along with representatives of its business partner, MagmaTech, joint winners with Ancon of the 2018 award.

It was a very proud moment for the two Ancon representatives who share over 50 years’ service and have played important strategic roles in the company achieving and maintaining UK market leadership and its significant international growth.

Speaking after the reception, Hervé Poveda said ”What a wonderful personal experience to meet the Royal family at Buckingham Palace and a great honour to be asked to represent Ancon at this event. A Queen’s Award not only recognises expertise in developing new products or achieving commercial success, but also excellence in every area of business. I am proud to be a part of an organisation that has proved itself, once again, to be among the best in the world.”

Peter McDermott added, “Winning one Queen’s Award is a great achievement, but winning three is a real measure of the depth of expertise, knowledge and dedication that exists within Ancon, at every level of the company. Today is a proud moment for every Ancon employee as well as our suppliers, customers and partners who have contributed to Ancon’s achievements throughout the world.”

Ancon’s latest Queen’s Award, for continuous excellence in innovation, comes as a result of expanding into advanced composites, with the successful introduction and on-going development of the ultra-low thermal conductivity Teplo range of basalt fibre wall ties, which improve the energy efficiency of masonry construction.

This success follows Queen’s Awards for International Trade in 2015, for three years of outstanding sales growth across new and existing export markets, and a Queen’s Award for Innovation in 2012, for the in-house development and commercialisation of a patented Lockable Dowel, a product that revolutionised the construction speed of post-tensioned concrete buildings.

The 2018 Award will be officially presented to Ancon later in the year when the Lord Lieutenant of South Yorkshire, HM The Queen’s local representative, visits the company’s recently-extended production facility in Sheffield.

View Ancon's profile:

Bona introduces wood floor styling at Clerkenwell

Story

As a showroom partner, wood floor specialist, Bona, through twice daily talks, will introduce the Clerkenwell community to its new ‘Inspiration’ wood floor styles, designed to transform the look of tired, existing wood floors or to embellish unfinished new ones.

As a showroom partner, wood floor specialist, Bona, through twice daily talks, will introduce the Clerkenwell community to its new ‘Inspiration’ wood floor styles, designed to transform the look of tired, existing wood floors or to embellish unfinished new ones.

Created by Bona in collaboration with internationally recognised trend analyst, Cay Bond, each of the 17 new looks can be achieved using a combination of Bona’s sanding and brushing methods to enhance the grain, followed by treatments with the company’s waterborne lacquers, oils and colours. The styles, Nordic Shimmer, Garden Atmosphere, Malibu Dreams, Touch of Grace and New Modern, include everything from dark, rustic floors to floors with a pale, lacquered finish.

Floor owners are often simply not aware of how an existing wood floor can be transformed, giving a room or space a completely new look and feel. From a sustainability perspective it makes sense too – the old floor has already been manufactured and transported.

A campaign starts on June 1st using social media, print and online advertising to target and inspire floor owners. Contractors will be able to use the professional pages at bona.com to see how the individual looks can be achieved, and samples and beautiful inspirational brochures will also be available for designers, architects and flooring contractors to leave with their clients.

Register for twice daily showroom talks entitled ‘Inspiration through renovation – how to achieve contemporary trends on existing wood floors’ at this link – https://www.bona.com/en-GB/Professional/Support/Events/Clerkenwell-Design-Week/ or via Bona’s Showroom page at clerkenwelldesignweek.com

View Bona's profile:

Expansion into advanced composites brings third Queen’s Award for Ancon

Story

Structural fixings manufacturer, Ancon, has won a 2018 Queen’s Award for Enterprise in the Innovation category, for the successful introduction and on-going development of its advanced composite, low thermal conductivity, Teplo wall tie range.

This is the third time that Ancon has been honoured in this prestigious award scheme that rewards outstanding achievements by UK businesses; it follows Queen’s Awards for International Trade in 2015 and Innovation in 2012.

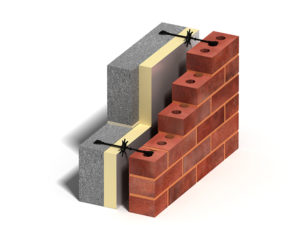

Teplo wall ties are manufactured from continuous basalt fibres set in a resin matrix; a fibre-reinforced polymer that is 70 times more thermally efficient than steel. When used to join the two leaves of a cavity wall, this material virtually eliminates cold bridging across the insulated cavity. Launched by Ancon in 2010 as part its market leading wall tie range, Teplo has had a major influence on the growth of low energy housing in the UK and Ireland, and helped future-proof traditional masonry cavity wall construction techniques, by minimising insulation thickness and wall footprint.

Whilst Ancon’s first Queen’s Award for Innovation in 2012 recognised the company’s in-house development of a unique lockable concrete-connecting steel component, this second Innovation award has been won jointly with its external strategic partner in this advanced composite development, MagmaTech.

Head of Marketing and Innovation at Ancon, Annabelle Wilson, says “Ancon launches a number of new and improved structural fixing solutions every year and invites ideas into our innovation process from both inside and outside the company. We saw potential in this new material immediately, and over the last eight years have committed our business resources to improving and extending the Teplo wall tie range as part of the Ancon product portfolio, bringing the benefits of advanced composites to mainstream UK construction.”

Today, the Teplo wall tie range includes Teplo-L suitable for surface-fixing in timber frame construction, the Teplo-BF with moulded safety ends that improve buildability particularly in lime and other slow-setting mortars, and the Teplo-BFR which can be resin-bonded in existing walls for retrofit applications. Teplo has been used in numerous ground-breaking developments, including the UK’s first masonry cavity wall ‘PassivHaus’, the UK’s first zero-carbon retrofit and the largest building in the UK built to the ‘Passivhaus’ standard, the University of Leicester’s Centre of Medicine.

Ben Williams, MagmaTech’s Managing Director says “Ancon has proven to be an exceptional partner for cutting edge innovation. They embraced a concept that was potentially disruptive to their existing stainless steel business, promoting it with passion and commitment. Taking a truly innovative energy-saving product to this level of market acceptance in just a few years is a truly outstanding achievement, surpassing our expectations.”

Commenting on their latest triumph in the Queen’s Award programme, Ancon’s Managing Director, Stuart Maxwell, says “Winning three Queen’s Awards in seven years is an extraordinary achievement and reflects the level of professionalism with which Ancon employees, in all areas of our organisation, go about their daily business. Our focus on quality and innovation, combined with a single-minded determination to excel in everything we do, not only underpins our brand reputation in the UK but its growing significance worldwide. It is another very proud day for everyone connected with Ancon and I thank our employees – both home and abroad – our customers and our suppliers for their continued support.”

Later this year the Lord Lieutenant of South Yorkshire will visit Ancon’s head office and main manufacturing site in Sheffield and officially present the 2018 award on behalf of HM The Queen. Ancon representatives will also attend a royal reception at Buckingham Palace this summer, hosted by HRH the Prince of Wales and other senior members of the Royal household.

Later this year the Lord Lieutenant of South Yorkshire will visit Ancon’s head office and main manufacturing site in Sheffield and officially present the 2018 award on behalf of HM The Queen. Ancon representatives will also attend a royal reception at Buckingham Palace this summer, hosted by HRH the Prince of Wales and other senior members of the Royal household.

View Ancon's profile:

How REHAU Recycles

Story

Ever wondered how old PVC-U window frames are transformed into brand new ones? Well wonder no more as Richard Hardstaff, General Manager at PVCR, explains it all:

Q: How easy is it to recycle PVC?

A: PVC is very straightforward to recycle and can be mixed with virgin polymer to give it a whole new lease of life. PVC can be recycled up to 10 times.

Q: Can any recycled plastic be used to make new window frames?

A: The types of material we deal with at PVCR are best recycled into new versions of themselves – so old PVC windows are transformed into new ones, old water bottles are made into new water bottles etc.

Q: Which PVC window frames can be recycled?

A: Ideally we want good quality de-glazed window and door frames to ensure the recycled material is of a good standard. Laminated frames are also OK to recycle.

Q: What processes are involved in recycling PVC?

A: Firstly, the frames are broken down and put into a shredder to reduce the size of the material, and any metal is removed. Next, the material is put in water and essentially everything we want sinks. We then separate the material again using a vacuum to ensure any rubber or leftover metal is removed before it goes into the granulator.

The granulator reduces the material to 10mm in size, before its washed, dried and put through electrostatic separation to remove any remaining residue or organic material. Its then colour sorted before the clean, white PVC material is ready to send to REHAU’s factory in Wales.

Q: What is the PVC material used for in the manufacturing process?

A: After being cleaned and lab tested, the white PVC material is sent to REHAU’s factory in Blaenau, where it used to make TOTAL70 co-extruded profiles.

Q: Is there growing demand for recycled PVC?

A: We have seen a dramatic increase in demand and by 2019 our capacity will have doubled, if not tripled.

Q: What’s the reason behind this uplift in demand?

A: Consumer demand is the main driver. By using recycled plastic, businesses can meet the needs of eco-conscious customers, give their products a USP, and do their bit for the environment.

For more information and to see the process in action visit www.pvcr.co.uk

View Rehau's profile:

Large span windows and doors set new design standard

Story

Much has changed in relation to door and window technology over the past 20 years and this is reflected in the increasing popularity of features such as large span roof windows and bi-folding doors. Both are now used as an intrinsic element of interior design as they enable natural daylight to transform areas in which we live and work.

For walls, use of floor to ceiling glazing has enabled exteriors to be ‘brought into’ the living environment, capitalising on views provided and enhancing perceptions of space. Design engineers are now, however, able to maximise the functionality of timber and aluminium to produce far larger sash and frame profiles than ever before. This requires a level of precision beyond the capability of traditional manufacturing techniques while, in terms of design complexity, durability, security and thermal / acoustic performance all have been considerably improved.

The type of timber used for the weight of such windows and doors is critical so Fakro opted for pine, oak and meranti hard woods to provide a combination of high performance and a high visual aesthetic. They also provide long-term structural stability, a critical factor not just for the ability to withstand distortion but to retain energy efficiency and airtightness. This was the driving factor influencing design of the Innoview range, in which triple and quadruple-glazed construction is used with low emissivity glazing and a quadruple sealing system. With warm spacers between panes, the overall heat transfer coefficients in is as low as 0.68/W/m2K (with Ug values of 0.3W/m2K in quadruple-glazed units).

Designs in which windows of such a large span are specified inevitably necessitates manufacture of bespoke sizes for individual projects. In achieving the ability to do so, Fakro can now fulfil the same service it has been providing with roof windows for more than 20 years. This enables architects and interior designers to create homes and work places with a distinctive identity and character while also meeting specific technical aspects of performance.

With scope to specify colours from the RAL Classic Palette and use of close-grain timber from FSC-certified sources, the standard of internal finish immediately provides clear evocation of quality. Modern coating and lacquering techniques, matt or satin finishes and choice of sash profile enable the windows and doors to complement the most diverse interior design requirements. Appearance is enhanced by concealed hinges and invisible fixings while use of sliders in conjunction with a roller lifter and rotary cam ensure that positioning in the frame remains constant, regardless of usage intensity. Soft closure also slows the sash movement prior to positioning it in the frame. Such ease of operation has been described as ‘out of all proportion to what might be expected from windows of such a size’.

EPDM rather than silicone seals are used as they provide far greater long-term reliability through their shrinkage resistance and bond between glazing and frame. This not only gives far greater assurance of air and weathertightness but provides a greatly improved standard of finishing. Windows and doors have anti-burglary, multi-point locks and Class RC1 or RC2 glazing units (the latter optional extra providing nine locking points per window). The hardware also has sufficient strength to provide a load capacity of up to 150kg in standard door and window sizes.

Fixed, arc and multi-sash windows with movable or structural mullion bar, balcony doors with a low aluminium threshold and tilt or lift and slide doors are available. Widths of up to 12 metres and heights up to 2.8 metres as well as non-standard shapes can be accommodated with single or double sash lift and slide doors up to a weight of up to 400 kg.

In terms of design innovation considerable attention has also been paid to external appearance with powder-coated aluminium outer cladding providing a combination of high performance and lasting appearance. The potential to specify the required colour and absence of visible welds at corners provides seamless, contemporary styling.

Products such as Innoview HST doors have virtually no visible while PSK tilt and slide doors provide scope for micro-opening to provide room ventilation without reducing the level of security. Such developments can only provide further incentive to change the face of contemporary fenestration while providing scope to do so in designs up to Passivhaus standard.

View Fakro's profile:

Condair at Data Centre World 2018

Story

Condair is appearing at the forthcoming Data Centre World exhibition on stand D1060, at the Excel Centre in London from 21st to 22nd March. The company will be displaying the latest in adiabatic and steam humidifier technology, which provides in-duct evaporative cooling and humidification to data centres.

Condair is appearing at the forthcoming Data Centre World exhibition on stand D1060, at the Excel Centre in London from 21st to 22nd March. The company will be displaying the latest in adiabatic and steam humidifier technology, which provides in-duct evaporative cooling and humidification to data centres.

Condair has extensive experience in working with data centre designers and air handling unit manufacturers that need to incorporate evaporative coolers or humidifiers into their systems. Previous data centre projects have involved clients such as Facebook, Microsoft, Digital Realty, Hewlett Packard, Amazon and eBay.

Condair’s experts will be on-hand at Data Centre World to give advice on how the latest humidifier technology can reduce data centre operating costs through improved energy consumption and reduced maintenance requirements.

Products on display include the Condair ME evaporative humidifier that offers 0.68kW of adiabatic cooling to an air handling system for every 1kg of moisture evaporated into the air stream. As the humidifier can provide up to 1,440kg/hr of humidity while operating on less than 1kW, it presents significant benefits to data centres using free air cooling systems. The technology can be employed to deliver direct or indirect evaporative cooling to facilities in warmer climates or add massive amounts of low energy humidification to data centres using cold, dry outside air in cold climates.

Alongside its market-leading in-duct evaporative system, Condair will have the Condair RS resistive steam humidifier on its stand. The Condair RS offers steam humidification to data centres without the need to frequently replace boiling cylinders, as is the case with many on-board humidification systems supplied with CRAC units. The humidifier has a scale management system that allows lime scale that builds up in the boiling chamber to fall into a removable tank at the base of the unit. Routine scale removal can be carried out by in-house maintenance staff in minutes, saving costs on consumables and maintenance time.

The Condair Group is the world’s leading specialist in humidification and evaporative cooling, with energy efficient, hygienic and innovative technologies for commercial, industrial and heritage applications. Condair is represented in the UK by Condair plc, which offers system design, manufacture, supply, installation, commissioning, maintenance and spares. Condair plc is the new name for JS Humidifiers following the organisation’s rebranding in October 2014. You can find out more by visiting the company’s website at www.condair.co.uk.

View Condair's profile:

New Condair RO for Better Humidity Control

Story

Condair is launching the Condair RO-A reverse osmosis water filter, specifically designed for use with humidification systems. The Condair RO-A removes 95% of dissolved solids from a humidifier’s supply water in order to reduce maintenance, improve energy consumption and benefit ongoing running costs.

When operating on regular mains water, a steam humidifier will frequently need to drain hot water and replace it with fresh, in order to dilute mineral levels in the boiling chamber. This process requires more energy to heat the incoming cold water. It also impacts humidity control, as when the boiling chamber’s temperature drops so does the steam output. By operating a steam humidifier on reverse osmosis (RO) water from a Condair RO-A, these drain cycles are reduced by up to 97%. This in turn reduces energy and water consumption of the humidifier and enables a close humidity control of up to ±1%RH.

With the use of virtually mineral-free RO water, the lime scale build-up inside a steam humidifier’s boiling chamber is minimal, reducing humidifier servicing requirements. When used with evaporative humidifiers, this reduction in lime scale formation results in evaporative pads having a much longer lifetime. The required frequency of an evaporative humidifier’s water tank drain cycles is also reduced, saving water. Operating spray humidifiers on RO water prevents dust from precipitating into the atmosphere as the spray evaporates, improving the performance of the system.

The Condair RO-A has been designed to deliver water at an ideal quality for humidification systems, whilst minimising waste water from the RO process. Many standard RO water filters provide product water at a purity that is much greater than that required to benefit humidifiers. The high purity means more water is sent to drain during the RO process to achieve a very low mineral content. By typically removing only around 95% of the minerals, the filtered RO water effectively provides significant benefits to humidification systems with minimal water being sent to drain.

Four models are available in the Condair RO-A range, with maximum outputs of 40, 100, 200 and 300 litres per hour. The 40 and 100 litres per hour models have an integrated water tank and a single RO membrane. The 200 and 300 litres per hour models have two or three RO membranes and an external water tank with up to 100 litre storage.

An independent wall-mounted touch screen controller provides an intuitive user interface with comprehensive reporting features. Alternatively the Condair RO-A can be controlled from any Condair humidifier that incorporates a Condair touch-screen control panel.

The Condair Group is the world’s leading specialist in humidification and evaporative cooling, with energy efficient, hygienic and innovative technologies for commercial, industrial and heritage applications. Condair is represented in the UK by Condair plc, which offers system design, manufacture, supply, installation, commissioning, maintenance and spares. Condair plc is the new name for JS Humidifiers following the organisation’s rebranding in October 2014. You can find out more by visiting the company’s website at www.condair.co.uk.

View Condair's profile:

AGILA OPENS UP NEW OPPORTUNITIES FOR FABRICATORS

Story

Since REHAU launched its AGILA sliding doors range sales of the PVC-U doors have been steadily growing and now more fabricators than ever are choosing to specify AGILA.

AGILA sliding doors are great for modern living, letting in light and creating openness in any space. They can be installed as a traditional patio door, entrance door or door to a conservatory, and are available in eight different colour options to provide a flexible solution which can be tailored to the individual needs of the customer. A perfect fit for REHAU’s popular TOTAL70 windows system, the AGILA sliding door also offers continuity of product across larger specifications.

As well as slimmer sightlines and superior aesthetics, AGILA sliding doors are incredibly energy efficient, with a triple glazing option on offer. They also come with enhanced security options and benefit from ERA’s new Total Security Guarantee for complete peace of mind.

Currently there are ten businesses fabricating the AGILA Sliding Door across the UK and Ireland. These include Climatec, Fenster Trade Frames, GRM, Polyframe, Euroglaze, Stormking, Hadrian, Costello PVC, O’Grady UPVC Ltd and Caledonia Doors in Cumbernauld being the most recent company to come on board .

To increase interest further, REHAU has released a new video online which highlights all the great features of the AGILA sliding doors to promote the product to fabricators and their customers.

Clare Higgins, Product Manager, from REHAU said: “The AGILA sliding door has been a fantastic addition to our doors offer, providing our partners with a high quality and flexible door solution they can offer to their customers individually or as part of a full portfolio of REHAU products. With the trend for large span doors continuing to gather pace in the domestic market, we expect to see even more contractors choosing to offer our sliding doors over the coming months and years.”

For further information please visit www.rehau.uk/agila.

View Rehau's profile:

WAGO joins forces with “Strategic Outsourcing Specialist”

Story

WAGO, the automation, interconnection and electrical interface specialist, has agreed a deal to supply components to PP Control & Automation for use in their electrical assemblies. The agreement is the latest in a series of new supplier partnerships struck by WAGO.

As one of the global leaders in electrical control systems, cable harnesses and sub-contract manufacturing solutions, PP Control & Automation serves building services, food and beverage, medical, energy, security, semiconductor manufacturing, printing and others. Customers are increasingly demanding more complex machines with shorter lead times. “Production capacity of particular machine configurations often has to be ramped up and ramped down at short notice. For this reason, the company needs suppliers that it can trust to provide reliable components to specification in a short space of time,” says Tony Hague, managing director of PP Control & Automation.

WAGO, whose interconnection and automation products provide the backbone for critical applications are supplying DIN rail-mounted terminal blocks, power supplies, electronic circuit breakers, and automation controllers and modules.

“Customers require a higher degree of configuration than ever before,” continues Hague, “And it’s up to us to provide exactly what they need. Things can move quickly in industry, and the increasing need for agility means that good product design and effective specification at component level are critical. Even the highest standards of workmanship can’t save you from inferior components, which is why partnerships with suppliers like WAGO are so important to us.

“In every case PP Control & Automation recommends and makes use of CAGE CLAMP® technology and the security of connection that it provides. We have already, on a number of occasions, replaced more traditional screw clamp connections with CAGE CLAMP, and our customers have seen an immediate and significant improvement in connection reliability.”

Tony Hoyle, managing director, WAGO Limited, adds; “We are always pleased to know that industry-leading OEMs such as PP Control & Automation choose WAGO products, and it demonstrates the high regard in which we are held within the market. A major benefit for us is that customers who may not ordinarily have specified WAGO get to see just what our products are capable of.”

View Wago's profile:

NEW TROX PWX FANCOIL RANGE REDEFINES ENERGY EFFICIENCY AND ACOUSTIC PERFORMANCE

Story

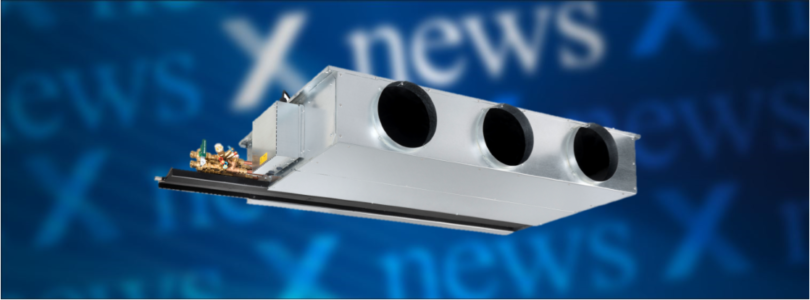

TROX has announced the launch of a major new fancoil range – the TROX PWX Series – which brings to the market a 25% to 35% energy efficiency improvement over alternative models, with outstanding acoustic performance, and BACnet-enabled integrated controls packages as standard.

The launch of the new TROX PWX fancoil range follows an extensive research and development programme in which the company rejected incremental product enhancements in favour of a comprehensive rethink of fancoil technology. The new products have undergone thorough in-house testing, using TROX’s test chamber (constructed to comply with ASHRAE 79, BS1397 and EUROVENT 6/3), in addition to extensive corroboration of results at an independent test facility. As a result, specifiers are able to input exact performance criteria for an extremely wide range of thermal and acoustic scenarios when planning their air conditioning schemes, instead of having to rely on less reliable ‘anticipated’ or ‘expected’ data. The TROX PWX range is therefore able to speed up the specification of projects significantly, reduce levels of risk, streamline installation and commissioning, and provide valuable environmental and cost benefits.

Whilst the basic physical dimensions of the TROX PWX units have been kept the same (270mm deep) to meet market requirements, every aspect of the thermal, electrical and acoustic performance of these models has been redesigned. With new inlet attenuators, inlet plenums and discharge attenuators, the units feature completely redesigned key components capable of achieving outstanding performance across a wide range of applications.

The SFPs across the range comply with and exceed Part L requirements, with typical values between 0.15 to 0.25 W/(l/s) at 30 Pa ESP, with a Guide NR of 35.

The environmental performance of the fancoils has been developed in conjunction with the full range of TROX air terminal device options. TROX’s unique ‘One Stop Shop’ solution enables correct selection of air terminal devices to be tailored to each fancoil. This optimises potential energy savings without compromising air distribution (a factor very often overlooked when specifying the systems independently). The ability to source the entire system from a single supplier also enables specifiers to optimise the performance of the fancoils in VAV (variable air volume) systems. The specification process has been speeded-up by the introduction of sophisticated new in-house product selection technology. This makes it possible to identify the most effective combinations of fancoils, grilles and diffusers more quickly, making it possible to specify fancoils for entire projects in just minutes, rather than hours.

The TROX PWX fancoils are supplied with specially-designed on-board controls packages, as standard. Two different STD controls packages are offered:

- BACnet control, offering the full flexibility of uniquely addressed terminal units, which interface with Building Management Systems (BMS) and provide feedback on each unit’s performance.

- TROX can also offer standalone controls that allow user control of individual units where no BMS is present.

To complement these control packages, TROX is also able to offer a full water-side control package which has been designed to work seamlessly with either control option.

These control solutions provide a number of valuable benefits. Project lead-times can be reduced significantly, as all wiring diagrams are pre-designed and readily available. This reduces the time and costs associated with additional electrical scheme design or expensive customisation of BMS programming. Specifiers also have the peace of mind that the controls technology has perfect compatibility with the fancoil units, and has been developed specifically to optimise performance in a way that is hard to replicate with ‘bolt-on’ controls.

A key factor in the development of the TROX PWX Series has been the thoroughness of testing, which removes the project risks associated with incomplete or uncorroborated performance data. By thorough testing in-house using its own BSRIA type test rig, and by sourcing detailed external data for the fancoils from extensive independent testing, TROX is bringing to the market a range of products with unrivalled, verifiable, specification data. Care has been taken to test the units at specified 30 Pascal external static pressures (ESPs) and to provide exact performance figures. This improves on industry practice where lower external static pressures might be employed during testing, culminating in misleading results.

This rigorous testing of electrical and thermal performance has been matched by extensive independent acoustic testing. The acoustic testing, carried out in accordance with BS EN 16583:2015, covers the entire PWX range, including all available fan configurations across the full operating range.

Such detailed acoustic analysis allows precise selection of units to suit the customer’s requirements and is complemented by TROX’s new selection process, enabling user adaptation of project-specific finishes that may affect the resultant room NR level. As the suspended ceiling finish has such a big impact on the room NR, TROX has worked closely with Armstrong Ceilings to pre-programme tested ceiling tile SRI values into its new calculation programme to ensure the correct acoustic assumptions are used.

The new TROX PWX Series is designed to replace the company’s earlier fancoil models. The range includes 6 different physical sizes of unit, with 9 possible airflow configurations and 16 different fan options. The units are designed for 4-pipe heating and cooling, 2-pipe cooling, or electric heating as standard. As TROX is able to supply almost every element of an air handling system, from AHUs to air terminal devices, key advantages for system designers and specifiers include the possibility of ordering the fancoils alongside VAV components and ATDs, from a single supplier, for a perfectly-integrated solution.