Category Archives: Energy

Marshall-Tufflex trunking pre-fabricated into Battersea apartment project

Story

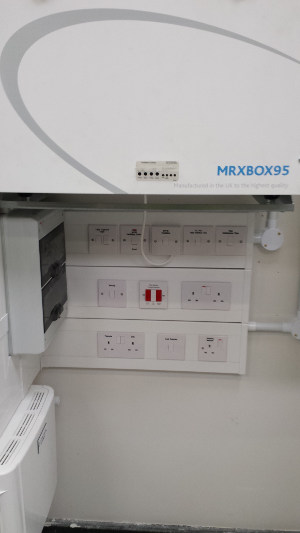

More than 500 apartments in the £9 billion revamp of London’s iconic Battersea Power Station have utility cupboards pre-fabricated with a cable management solution from leading British manufacturer Marshall-Tufflex.

The cupboards were assembled off-site and delivered complete with Marshall-Tufflex Sterling Profile 3 white trunking to supply power for apartment ventilation and heat interface units, cupboard lighting, hot water, the fire alarm and security system, satellite television, BT networks, a leak detection panel and washing machine. A ‘non-power’ section carries EMS wiring and outgoing data, telephone and TV cables together with a link to energy metering/billing services. Electrical wholesaler was Edmundson Electrical, Twickenham.

“This has been a really interesting project to work on for two reasons,” said Marshall-Tufflex Project & Specification Manager, Barry Roberts. “We are best known for working in the commercial cable management sector, so to supply a large and prestigious domestic project was an interesting request. It is also somewhat unusual for trunking to be pre-fabricated in this manner but for this project it made total sense and allowed for an integral element of each apartment to be prepared in a controlled environment and simply slotted into place and connected up at exactly the right time in the build schedule.

“Marshall-Tufflex’s Sterling Profile 3 has delivered an incredibly neat finish that keeps all cabling hidden and inaccessible while delivering a large amount of power and data cabling to the required services. Its square edges fit cleanly together and multi-compartments allow for versatility and full segregation of services,” added Mr Roberts.

Sterling Profile 3 is 167 x 50mm and available in a variety of colours and finishes, with a range of corners, flat angles, bends and tees available. Dividing fillets allow further segregation of services within each compartment and aluminium screening inserts or conductive spray coatings are available to assist with both electromagnetic immunity and emissions.

View Marshall-Tufflex's profile:

Armourcoat Acoustic creates a calm and inviting environment

Story

Decorative specialist Armourcoat exhibited at the Decorex International Exhibition in September. Taking place at the start of the London Design Festival in the grounds of historic Syon House, Decorex is synonymous with luxury design offering a collection of over 400 hand-selected exhibitors.

Armourcoat presented a stunning range of hand-applied polished plaster wall finishes and the latest additions to the Signature Collection. The company also launched their new Armourcoat Acoustic Plaster System designed to optimise the acoustics of interior spaces.

From large theatre halls, offices, classrooms, hotel receptions and private residences the use of hard sound reflective surfaces such as glass, wood and stone can cause excessive sound reverberation which leads to unpleasant noise levels. The Armourcoat Acoustic Plaster System offers a clean and smooth mineral surface that can be applied seamlessly over large expanses to both flat and curved surfaces. The correct control of sound can create a calmer and more pleasant environment.

Comprising of a special mineral wool composite panel that is bonded onto the substrate and finished with a seamless layer, the Armourcoat Acoustic Plaster System offers an elegant marble based plaster finish while allowing sound energy to pass through the surface. The zero VOC system, which consists of 80% recycled material, achieves class ‘0’ fire rating and a class ‘A’ Noise Reduction Coefficient rating.

An array of global projects for an impressive list of international blue chip clients in the residential, hospitality and boutique retail sectors have established Armourcoat as a leading supplier of high quality surface finishes. Armourcoat products are made from natural minerals including recycled Italian marble, contain low or zero VOCs, and have the added confidence of a full 10 year guarantee.

View Armourcoat's profile:

Wakaflex lead-free flashing for ultimate performance

Story

Lead flashing work normally requires a specialist roofer and can be hazardous to the installer if strict health and safety procedures aren’t adhered to.The price of lead can also be prohibitive for basic upstand work.

This has prompted introduction of a large number of lead-free flashings, though Klober Wakaflex® stands apart as one of the longest established and highest performing. BBA-certified and with a 20-year guarantee, it is ideal for all roofing types including clay, concrete, slate, metal and polycarbonate. Available in, light grey, anthracite, brown and terracotta (the latter two to special order), it has an aluminium ‘honeycomb‘ mesh embedded into UV-resistant butyl rubber which gives the product similar malleability to lead but with no scrap value. Unlike lead, it can be stretched by up to 50% in length and 15% in width and with no susceptibility to thermal movement it can be laid in long lengths without fixing clips. With no need for forming or other specialist tools Wakaflex provides lasting performance regardless of detailing complexity and can be shaped around deeply profiled tiles or used to seal the top saddle and roof penetrations.

Wakaflex has a high-strength, self-adhesive Butylon® backing which provides immediate weatherproofing and on laps chemically bonds to the facing to provide a virtually unbreakable seal. It is environmentally safe, presents no contamination problem with water run-off and can therefore be used with rainwater harvesting systems.No heat, solvents, adhesives or other additional means of fixing are needed and installation can take place in temperatures from minus 40 – 100⁰C, normally without priming.

For details of a local merchant stockist call FREE on 0800 783 3216.

http://klober.co.uk/shop/product/wakaflex

View Klober's profile:

Air Curtains by Design

Story

Architects and consultants can now enjoy a freehand with air curtain design thanks to the Zen from JS Air Curtains. Fascia panels can be custom made in many different materials, screen printed to carry logos or images, and manufactured to incorporate elements such as clocks and LED displays.

Materials designers have specified on custom Zen fascias range from stainless steel, wood, PU leather, high impact polystyrene and PET, each chosen to perfectly match the architecture of the entrance. As the fascias can also be provided with vinyl graphics, fire exit signs and illuminated 3D lettering, the possibilities are limited only by the designer´s imagination.

A “visual installation service”, by JS Air Curtains, allows a designer to preview their creations with a realistic digital mock-up of the air curtain in-situ using an image of the entrance supplied by the client.

The Zen air curtain is supplied as standard with anodized aluminium fascia panels and a galvanised steel central structure finished in black forge; other RAL colours available on request. The unit can be mounted on brackets or drop rods horizontally above doorways up to 4.2m high to seal the entrance with an invisible barrier of air. This helps prevent cold air entering in the winter and cool conditioned air escaping in the summer.

The air curtain is easy to install and available in 0.5m lengths from 1 to 2.5m with the option to join units to cover very wide entrances, making it ideal for use in shops, restaurants, hotels and public buildings.

Heating can be via LPHW, electric or heat pump or alternatively the Zen is available as an air only, non-heated air curtain. Low noise, double-inlet centrifugal fans provide up to 2,700m3/h of airflow per metre of air curtain, with an option for an energy saving EC model. The discharge grille and air intake are in the same plane on the air outlets, so that the air flows through the unit in a straight line, creating a more powerful throw and a tighter seal across an entrance.

The Zen air curtain is supplied, as standard, with a manual controller with five fan speeds with three heater stages on electrically heated models. Seven metres of control cable and an infrared hand-held remote are included. The unit can also be connected to a BMS using protocol Modbus RTU.

A variety of different sensor and switch options can be combined with the Zen’s controllers, including door switches, so the unit only operates when the door is open, time switches, so the units activate during certain hours, and room thermostats, so a constant internal temperature can be maintained.

JS Air Curtains, the UK’s leading air curtain specialist, supply an extensive range of air curtains for all commercial and industrial applications.

View JS Air Curtains's profile:

UNMISSABLE !

Story

UNMISSABLE !

This year’s National Painting and Decorating Show is a must-see! The biggest and best yet, it is your opportunity to see the latest products, proven best sellers, preparation tips and finishing techniques that will be making the news in 2018 and beyond.

Painting and decorating contractors , interiors designers ,merchants , refurbishment specialists and facilities managers are always on the lookout for the latest colours, materials and textures – as well as the best tools to get every job done quickly and profitably.

A great day out

It really is an action-packed two days buzzing with –

- new product launches

- practical demonstrations

- fantastic show-only deals

- free samples

- hands-on trials

- fun competitions, raffles and prize draws

- sporting challenges and celebrity appearances.

Big discounts

The major manufacturers use the show to bring new products to market, while stockists tempt visitors with big discounts, and suppliers pack their stands with extensive selections of tools, ancillaries and workday essentials.

See the masters at work

Brush and roller techniques, abrasives innovations, spray demonstrations, new decorative effects . timber repair are just some of the presentations by experts taking place every 30 minutes in two ‘open-area’ MasterClass theatres situated right in the centre of the exhibition. Check out the daily programme in your FREE showguide.

PRE-REGISTER NOW – IT’S EASY…..

Pre-register today for FREE tickets at www.paintshow.co.uk

RICOH ARENA,COVENTRY, 28th and 29th NOVEMBER

View National Painting & Decorating Show's profile:

Wakaflex lead-free flashing for ultimate performance

Story

Flashing work often requires a specialist roofer and can be both time-consuming and costly. Leadwork is also potentially hazardous to the installer if strict health and safety procedures aren’t adhered to.

This has prompted the introduction of a host of lead-free flashings, Klober Wakaflex® being both one of the longest established and highest performing. BBA-certified and with a 20-year guarantee, it is ideal for all roofing abutment work and roof types including clay, concrete, slate, metal and polycarbonate. Available in, light grey, anthracite, brown and terracotta (the latter two to special order), it has an aluminium ‘honeycomb‘ mesh embedded into UV-resistant butyl rubber which gives the product similar malleability to lead but with no scrap value. Unlike lead, it can be stretched by up to 50% in length and 15% in width and with no susceptibility to thermal movement it can also be laid in long lengths without fixing clips. With no need for forming or other specialist tools Wakaflex provides lasting performance regardless of detailing complexity and can be shaped around deeply profiled tiles or seal the top saddle and roof penetrations.

Wakaflex has a high-strength, self-adhesive Butylon® backing which provides immediate weatherproofing and on laps will also chemically bond to itself to provide a totally secure seal. It is environmentally safe, presents no contamination problem with water run-off and can therefore be used with rainwater harvesting systems.No heat, solvents, adhesives or other additional means of fixing are needed and installation can take place in temperatures from minus 40 – 100⁰C, normally without priming.

Wakaflex is available from builders and roofing merchants nationwide.

http://klober.co.uk/shop/product/wakaflex

View Klober's profile:

Power quality analyser gives Class A versatility

Story

The versatile MPQ1000 offers oscilloscope and DVM modes. In both modes it can monitor and record power, energy, RMS voltage and current, harmonics, inter-harmonics, harmonic direction, THD, TDD, flicker, unbalance, rapid voltage change (RVC), mains signalling and phase angle deviation as well as sags, swells and transients down to one microsecond. It also performs waveform analysis up to the 128th harmonic in real time.

Data gathered during testing can be recorded by simply pushing a button. The instrument automatically detects current clamps, recognizes the range, identifies the nominal voltage and sets the triggers, after which it verifies that the unit is properly connected before allowing a test to commence.

On-board data analysis is provided, and a removable SD card can be used to expand the instrument’s memory capacity easily and inexpensively. All data recorded can be viewed on the integral VGA colour display and can also be transferred to Megger’s power quality analysis software for more advanced analysis, reporting and archiving.

The PC-based software supplied at no extra cost with the analyser automatically creates custom configurations based on user requirements and facilitates tailored automatic data analysis. It also allows users to create their own analysis templates that can be loaded into the analyser.

To complement its versatile handheld MPQ1000 power quality analyser, Megger offers flexible current clamps that have four selectable ranges from 0 to 6000 A.

View Megger's profile:

FAKRO roof windows for Aberdeenshire Passivhaus self-build

Story

FAKRO FTT U6 and FTP U5 Electro triple-glazed roof windows were used on Carsluchie Croft, a Passivhaus project which maximises controlled solar gain The compact 1½ storey form reflects local vernacular architecture, with the angled bay on the south side designed as a dynamic element to contrast with the compact solid stone-clad form of the majority of the house. The FTT U6 has an exceptional U-value of 0.81W/m2K while the FTP U5 windows also had Z-wave connectivity enabling them to be operated from a laptop, mobile or tablet. All windows were also fitted with thermal flashings to enhance airtightness.

View Fakro's profile:

A luxurious prospect at New York’s Whitby Hotel

Story

New York City’s newest boutique luxury hotel makes a bold statement in upper midtown Manhattan, thanks in no small part to the extensive use of Crittall steel windows, doors and internal screens and partitions.

The Whitby is the second in New York opened by Firmdale Hotels whose owners, Tim and Kit Kemp, have already made a big impression back across the pond with several stylish and luxurious properties in central London including Ham Yard and Soho that also exemplify the use of fenestration by Crittall.

Opened in late February, The Whitby is described as a celebration of contemporary art and design boasting a stylish restaurant, bar and conservatory as well as a colourful library, several private event spaces and a state-of-the-art cinema. Each of the 86 bedrooms has been individually styled with Kit Kemp’s world-renowned mix of colour, pattern, texture, and art.

Located on West 56th Street between 5th and 6th Avenues, The Whitby is just two blocks from Central Park. It is surrounded by world-class department stores, luxury designer boutiques and is a short walk to Broadway.

Its location informed the specific choice of glazing. At Firmdale’s other NYC hotel, on Crosby Street, W20 steel windows were used. The Whitby’s position called for even higher acoustic attenuation and so Crittall MW40 fenestration was selected. These windows can accept up to 30mm thick glazing providing excellent acoustic as well as thermal performance.

Nevertheless, the sight lines are virtually the same as with the Corporate W20, that is to say the slender frames provide for maximum daylight while ensuring strength and security. All The Whitby’s guest rooms have floor to ceiling windows as a principal feature.

The ground floor meanwhile (the first floor in American parlance) also features interior screens and lobby doors by Crittall employing a single-glazed W20 profile. These are especially versatile for use in association with door hardware, closers, card entry equipment and so forth, dependent on their use. Facing the streetscape at ground level are Corporate 20 windows; large full panewindows that are even more robust than MW40s and which accept up to 28mm glazing.

The Whitby has been designed by New York architectural practice Stonehill &Taylor, which also designed the Crosby Street Hotel. The Whitby presents an elegant limestone façade rising 18 storeys and featuring several balconies and terraces that create a distinctive shape, stepping back as the building rises from street level.

The building harmonises with the architecture of the immediate neighbourhood, particularly Fifth Avenue. Says Paul Taylor, lead architect on the project, and president at Stonehill & Taylor:

“The Crittall steel windows are imbued with old world craftsmanship

and have the narrow sightlines that architects wish for.”

Contractors for the project were Flintlock Construction Services LLC.

View Crittall's profile:

Bona Titan – a new generation of powerful adhesives

Story

Bona, the wood floor experts, has launched Bona Titan, a new supreme performance, silane- based adhesive for high value projects, very wide or oversized solid wood boards – or any installation where the quality of the bond has to be guaranteed.

Bona Titan contains Titanium Technology – a revolutionary new formula comprising quadruple crosslinking that delivers superior durability and an unbeatable initial bond speed – even under challenging subfloor conditions.

Bona Titan can be specified with confidence to bond all types of wood flooring. Its superb shear strength makes installation easy and keeps even the largest, solid boards securely in place. If the subfloor is sound and dry, no primer is required.

The hard, silane-based formula contains no ingredients that can migrate after curing, which eliminates all risk of discolouration at the joints. The smooth, thick consistency makes it easy to use and produces stable ribs, an extremely high initial grab and zero risk of hollow spots. The bond strength of Bona Titan will not diminish over time so the stability of the floor is guaranteed for the long term.

Bona Titan meets ISO 17178 standards and, in line with Bona’s environmental strategy, is a safe, clean formulation which also carries EC1-R Plus, DIBt, Greenguard and A+ low emission certifications.

Bona Titan is compatible with underfloor heating and can be used directly on metal or tiles. Floors bonded with Bona Titan can be sanded after just 12 hours.

Further technical information is available at bona.com or from Bona’s technical department on 01908 525 161.