Category Archives: Energy

Animation explains new approach to heating for new-build homes

Story

Heat pump manufacturer, Mitsubishi Electric has just released a short animation which explains the new approach to heating and hot water provision now available from the latest addition to the Ecodan range of air source heat pumps.

Heat pump manufacturer, Mitsubishi Electric has just released a short animation which explains the new approach to heating and hot water provision now available from the latest addition to the Ecodan range of air source heat pumps.

As the nation looks to build new homes to meet demand, the hot water requirements of these houses requires a different approach, to help reduce emissions whilst delivering warm and cosy places for people to live.

Buildings account for 44 per cent of all UK CO2emissions (more than industry or transport) and space heating and hot water account for almost 75 per cent of total energy consumed in homes.

Yet the balance between hot water and heating is different in new built properties is different from older homes because of a reduction in fabric U-values and thermal bridging, which reduces the energy requirements for heating and makes hot water the dominant load.

The animation explains how the new 4kW Ecodan QUHZ unit works to efficiently match the hot water requirements, whilst still meeting the lower heating demand of today’s well insulated properties.

To find out more about the Ecodan QUHZ visit http://ecodanerp.co.uk/180 and to view the animation, visit the company’s dedicated video channel at https://www.youtube.com/user/mitsubishielectric2 .

View Mitsubishi Electric's profile:

Klober launches over-rafter insulation boards

Story

Klober has launched Permo® therm, a Kooltherm® insulation board with tongue and groove edges, integrated underlay and self-adhesive edge strips for sealing laps. With full LABC approval, it is suitable for all pitches but, unlike square-edged boards won’t provide an air leakage path. Permo therm is installed as over-rafter insulation and therefore provides added height within the roof space. Boards are 80 mm thick and can be laid on boarded or un-boarded roofs, either from left to right or right to left. No ventilation of the batten/counter-batten cavity is needed with most tiles or slates as these are primarily classed as air-open but for impervious or tight-fitting roof coverings ventilation is necessary. A range of fittings are available to ensure correct installation, thermal performance and airtightness including a Universal Roll for dressing over ridges, hips, valleys, verges and abutments. These can be used to complement Klober’s range of airtightness tapes and sealants.

Klober has launched Permo® therm, a Kooltherm® insulation board with tongue and groove edges, integrated underlay and self-adhesive edge strips for sealing laps. With full LABC approval, it is suitable for all pitches but, unlike square-edged boards won’t provide an air leakage path. Permo therm is installed as over-rafter insulation and therefore provides added height within the roof space. Boards are 80 mm thick and can be laid on boarded or un-boarded roofs, either from left to right or right to left. No ventilation of the batten/counter-batten cavity is needed with most tiles or slates as these are primarily classed as air-open but for impervious or tight-fitting roof coverings ventilation is necessary. A range of fittings are available to ensure correct installation, thermal performance and airtightness including a Universal Roll for dressing over ridges, hips, valleys, verges and abutments. These can be used to complement Klober’s range of airtightness tapes and sealants.

View Klober's profile:

Marflow Hydronics announces new product downloads

Story

Marflow Hydronics has further developed its website to now allow customers to download relevant technical information, including BIM Models, via a brand new Product Downloads section.

Marflow Hydronics has further developed its website to now allow customers to download relevant technical information, including BIM Models, via a brand new Product Downloads section.

With BIM Level 2 being a new requirement from April 2016 and the move towards complete BIM compliance getting closer every day, Marflow Hydronics has introduced a brand new Product Downloads area on its website that allows people to download BIM Models as well as other technical documentation. Marflow Hydronics is dedicated to providing customers with the information that they require, and this is just another part of the company’s added value service. In addition, all product pages can now be captured in PDF format at the press of a button and can be used as a data sheet, another way the company is trying to make life easier for product users.

Chris Forbes, Managing Director, says, “We are continually seeking to add value for our customers and we are constantly looking at ways to develop our website further to provide people with access to the information they need. The Product Downloads area is very new and we will be working hard over the coming weeks to make sure all relevant documentation and BIM Models are included. We encourage our customers to let us know if there’s something they need that they can’t find.”

The new Product Downloads area can be accessed via the relevant button at the top of all product pages or in the Knowledgebase. Also on all product pages, there’s a new PDF Download button that will export the product information into a PDF at the click of a button.

Access to the new area is found on the Marflow Hydronics website: www.marflowhydronics.co.uk.

View Marflow Hydronics's profile:

Valerie Owen OBE – The BBA announces new Chair of BBA’s Governing Board

Story

Valerie Owen was appointed Chair of the BBA’s Governing Board in February 2016. On her appointment, Valerie said: ‘I am delighted to take on this worthwhile position. As the UK’s leading Certification body for innovative building materials and construction installation techniques, the BBA has a key role to play in helping drive forward the construction sector, which is such an important contributor to our economy.’

Valerie Owen was appointed Chair of the BBA’s Governing Board in February 2016. On her appointment, Valerie said: ‘I am delighted to take on this worthwhile position. As the UK’s leading Certification body for innovative building materials and construction installation techniques, the BBA has a key role to play in helping drive forward the construction sector, which is such an important contributor to our economy.’

Valerie is a multi-disciplinary property professional – she is a member of the Royal Institute of British Architects (RIBA), the Royal Town Planning Institute (RTPI), the Royal Institute of Chartered Surveyors (RICS), the Chartered Institute of Arbitrators (CIArb), the Royal Society of the Arts (RSA) and the Chartered Society of Environmentalists (CEnv).

An expert in economic and sustainable development, Valerie is a co-founding director of Le Vaillant Owen Consultancy, an innovative company specialising in sustainable development and community regeneration. The business was established in 2004, with offices in London and Kent. In her earlier executive career, Valerie was a Director of international real estate Consultants Jones Lang LaSalle, after which she worked as Managing Director at London First, where she delivered economic development programmes in sustainable development, housing, regeneration and health in collaboration with local, national and regional Governments.

Valerie operates at the highest levels, and now has a portfolio career comprising a number of nonexecutive Directorships and Ministerial appointments. Valerie is Chair of Swan Housing Group which is currently regenerating 1,600 homes on the Blackwall Reach estate in Tower Hamlets, London; she is also Chair of Lantra, the Sector Skills Council for land-based and environmental industries.

In 2001 Valerie was made an OBE for service to ‘architecture, and the community in East London’. In December 2009 she was made a Cabinet Office Ambassador to champion equality and diversity in Ministerial/Public Appointments, and in 2015, she won the prestigious Lifetime Achievement Award in the National Women in Construction Awards.

Valerie is married to Bob Le Vaillant and has three daughters.

View BBA's profile:

ECODESIGN FOR ENERGY-RELATED PRODUCTS (ERP)

Story

Fläkt Woods are prepared for the EU-regulations Ecodesign ErO 1253/2014 and 1254/2014 regarding Air Handling Units and energy labelling for non-residential and residential buildings

Fläkt Woods are prepared for the EU-regulations Ecodesign ErO 1253/2014 and 1254/2014 regarding Air Handling Units and energy labelling for non-residential and residential buildings

With the Ecodesign directive 2009/125/EC, the European Parliament creates a framework which allows the EU commission to produce regulations for energy related products to achieve the 2020 goals;

- 20% reduction of greenhouse gas emissions

- 20% share of renewable energy

- 20% better energy efficiency

Fläkt Woods welcome these initiatives as they are fully in line with their strategy to develop energy efficient and smart product and solutions which benefit occupants, property owners and our shared environment.

ECODESIGN – CARING FOR THE FUTURE IS A SHARED RESPONSIBILITY

Under the Directive (2009/125/EC) Ecodesign for Energy-related Products (often mentioned as ErP) the first 13 implementing measures are estimated to allow about 365 TWh yearly savings by 2020, equivalent to more than 12% of the final EU electricity consumption in 2009. Electric motors alone are estimated to contribute more than 35% of these savings.

Fläkt Woods as a supplier of Air Handling Units, fans and ventilation solutions are already prepared to adhere to these directives concerning Ecodesign for Energy-related Products (ErP) as this is important for us to take our corporate social responsibility, and to help our customers to minimize the climate footprint.

To read this section in full > http://www.flaktwoods.co.uk/support-centre/legislation/ecodesign-and-erp/

Link to Flakt Woods Legislation page >http://www.flaktwoods.co.uk/support-centre/legislation/

View Flakt Woods's profile:

THERE’S ‘RENEWABLE’ GOLD, IN THEM THAR HILLS!!

Story

When Paul and CatheHazlewood decided to leave the agreeable urban living environment they had enjoyed for years in the centre of Oxford, looking for a new life in the country, they and Cathe’sbrother and sister-in-law decided to head for deepest Dorset.

When Paul and CatheHazlewood decided to leave the agreeable urban living environment they had enjoyed for years in the centre of Oxford, looking for a new life in the country, they and Cathe’sbrother and sister-in-law decided to head for deepest Dorset.

The sale of their properties allowed them to shop around for an idyllic setting that they could remodel to suit the lifestyle choices they wanted to make with energy efficiency, ‘green’ living and utilising modern renewable technologies an important factor in their decision-making.

What they found exceeded their wildest dreams and allowed them to reshape their futures in a way that whilst they had hoped might be possible, they needed to see to believe. The property they purchased allowed them both to enjoy large adjoining semi-detached properties, on a plot that included a large building that had been built and envisaged as a ‘business centre’ although it had never quite managed to be that, extensive woods and views across the Dorset countryside to die for.

Paul and Cathe admit they were not renewable experts. Being intelligent people they had a grasp of what was available but knew only a little more than the average person when it came to what they could go with and how those options might fit together. They were convinced they would go with solar PV to generate their electricity – the properties they had chosen were blessed with south east and south west facing roofs – and were sizeable, allowing them to install a solar array that would more than meet their requirements. They thought they might possibly go for a biomass boiler option – they had the woods and a pretty much endless supply of fuel available so they wouldn’t necessarily be reliant on a supply of expensive wood pellets.

They had an initial successful environmental ‘hit’. They inherited a home that was lit entirely by halogen lamps set into ceilings around the home. They quickly switched these all to LEDs and cut their lighting bill by 90%. This and the impending arrival of an 18kW solar PV system on the roof was beginning to shape the future for the couple. But the deeper they got into planning their future the more they began to realise they needed to talk to someone. Someone they could trust who really understood renewables and how they might work together to provide the best energy solutions for them. There is no ‘off the shelf solution’ – it needed someone who really understood the options to sit down with them, take them through the options and lead them gently towards the holy grail – an integrated heating, hot water and lighting system that met their very particular needs.

They had an initial successful environmental ‘hit’. They inherited a home that was lit entirely by halogen lamps set into ceilings around the home. They quickly switched these all to LEDs and cut their lighting bill by 90%. This and the impending arrival of an 18kW solar PV system on the roof was beginning to shape the future for the couple. But the deeper they got into planning their future the more they began to realise they needed to talk to someone. Someone they could trust who really understood renewables and how they might work together to provide the best energy solutions for them. There is no ‘off the shelf solution’ – it needed someone who really understood the options to sit down with them, take them through the options and lead them gently towards the holy grail – an integrated heating, hot water and lighting system that met their very particular needs.

Living in deepest Dorset, there might have been initial panic. Would they find such a person, or such people. They were recommended to talk to local experts Bublshop. Bublshop had been operating in the area under its name and a previous one – Dorset Energy Solutions – for several years and was driven by two knowledgeable guys – xxx xxx and Martin Perrin, both dedicated to working with renewable options, both well versed in the options available and with the experience to be able to advise pretty much anyone about what was best for them. Specifically. And that is exactly what they did for Paul and Cathe.

After a lengthy chat they decided to start with the solar PV system and then rather than going with biomass, to look at the latest high temperature air source heat pump from LG as the source of their heating and hot water. The homes they had bought were both fuelled by elderly and inefficient oil boilers and they quickly realised that that was not the way forward for them.

The solar PV 18kW array would see them exporting around 50% of the electricity they generated. They were attracted by the idea of storing electricity if they could but decided to put of this extension of the system until the technology to do it was cheaper and more reliable. It’s on their agenda!

The solar PV 18kW array would see them exporting around 50% of the electricity they generated. They were attracted by the idea of storing electricity if they could but decided to put of this extension of the system until the technology to do it was cheaper and more reliable. It’s on their agenda!

The feed in tariff (FIT) and Renewable heat incentive (RHI) weren’t essential decision makers for the solar PV or the heat pump although it was a significant help especially for the heat pump: “It is a nice bonus,” says Paul, “but it wasn’t a dealmaker or breaker. Because of the sale of our home in Oxford, we could pay for these up front, but the heat pump decision might have been a bit more difficult if we hadn’t had the RHI payments to look forward to over the next seven years.”

The LG Therma V high temperature air source heat pumps – one for each home – have been a huge eye opener to the couple. They had got used over twenty years to heat on demand using a traditional boiler. They had got used to the ease of having gas through the mains. There was concern initially about how responsive the air source heat pumps would be to deliver heat and hot water when it was needed. But with the latest ‘high temp’ system from LG they say they shouldn’t have worried: “It’s not a flippant remark,” says Paul, “but the heat pump is up and running and commissioned and the biggest compliment I can pay it is that we don’t actually notice the difference! It’s pretty rapid to respond – we’d heard stories about having to switch the thing on several hours before you needed hot water – but that’s just not the case. You quickly adjust to the new kit and it’s been excellent for us since we moved in and got it up and running.”

Bublshop’s Martin Perrin says this is the beauty of the new high temperature heat pumps from LG: “Low temperature air source heat pumps really need to be on 24 hours a day to bring the temperature of the home up to the required temperature and keep it there. They work well and for the right home, they do a great job. But if you need the security of almost instant response the high temperature ASHP is the one to choose. And they’re not hugely more expensive than the low temperature units. People who have them use them very much like boilers and they respond to that kind of use. The key to success is to get the heating system design right at the outset. Work through what you need, your lifestyle requirements and build those into a hardware design that delivers it. It sounds simple and is when you have considered all the complications. Once it’s sorted, it works a treat.”

We know its far more energy efficient and much more environmentally friendly to use renewables than fossil fuels. But what about costs?

“It’s difficult to be exact because we don’t have historical oil usage figures for the properties here – so we can’t measure or compare the costs but in our experience the savings over oil are in excess of 50% per year – and that’s impressive,” says Martin. We will be monitoring the ‘real time’ costs of the air source heat pump and we’re confident it will be mightily impressive when compared with any other forms of heating and hot water comfort provision.”

“It’s difficult to be exact because we don’t have historical oil usage figures for the properties here – so we can’t measure or compare the costs but in our experience the savings over oil are in excess of 50% per year – and that’s impressive,” says Martin. We will be monitoring the ‘real time’ costs of the air source heat pump and we’re confident it will be mightily impressive when compared with any other forms of heating and hot water comfort provision.”

In modern homes, with several bathrooms – certainly a couple of en-suites and a family bathroom becoming commonplace – and the new standards of insulation and heating, it’s common to see heating demand halved and hot water demand tripled – so high temperature air source heat pumps are ideal for this scenario – perfect for refurbishment projects like this one – but spot on for new build properties.

“The way homes are built these days is very different and the issues we face have changed hugely,” says Martin. “We’re delighted to have access to the technology we have from LG through the distributorship we have in this area. It gives us huge competitive advantage and a range of new options that we know work, that are cost effective and energy efficient and that allows us to combine renewable technologies in a way that we haven’t been able to before.”

To find out more about LG high temperature air source heat pumps head to http://partner.lge.com/uk, or www.bublshop.co.uk or you can email LG at HVAC.marketing@lge.com.

View LG's profile:

STELRAD PLANARS FIT THE BILL IN RESIDENTIAL REFURB PROJECT

Story

When Catherine Jackson wanted to add an extension to her home and refurbish part of her existing property in Beverley in the East Riding of Yorkshire, she decided that she wanted something special for the heating system. Although the original radiators were in good shape, she decided to invest in smart new radiators for the existing part of the large new extension at the rear of the home and add these new radiators to the extended kitchen and day room that was being built there.

When Catherine Jackson wanted to add an extension to her home and refurbish part of her existing property in Beverley in the East Riding of Yorkshire, she decided that she wanted something special for the heating system. Although the original radiators were in good shape, she decided to invest in smart new radiators for the existing part of the large new extension at the rear of the home and add these new radiators to the extended kitchen and day room that was being built there.

She selected the Stelrad Planar, a slim, flat fronted, minimalist designer radiator to achieve the contemporary look and feel she was after and the Planar met this brief perfectly especially with the vertical Planar fitting a space where wall space was at a premium.

She chose a large Caliente tubular rail design for the refurbished laundry room with its modern stylish looks but also for its large heat output which meant it was ideal for drying clothes as well as heating the room space.

“The project took around four months from start to finish and we’re all very happy with the outcome,” says Catherine. “The Planars have done the job I wanted them to and the Caliente Rail is a focal point of the décor in the laundry room – so all in all, I’m delighted with the decisions we made!”

The project saw the inclusion of five horizontal Planar radiators, one vertical Planar in the new open plan kitchen area and the Caliente Rail in the adjacent laundry room.

“We’re seeing Planars selected more often for residential opportunities,” says Stelrad’s Marketing Communications Manager Sarah Baker. “The slim good looks with the attractive flat front panel really does lend itself to projects where customers want something a bit more special for their homes. And the wide range of sizes it’s available in make it perfect for pretty much any refurbishment project – there’s a Planar for almost any wall space you care to mention.”

As well as being selected for residential refurbishment projects, Planar is increasingly popular with new build developers and in commercial developments where good looking radiators are required particularly front of house for reception and waiting room type opportunities. Stelrad has recently launched its Heavy Duty Planar – for use in commercial applications where a more robust radiator is required that can stand up to slightly rougher treatment than a standard radiator will have to cope with – ideal in warehouse or distribution settings where small vehicles often towing trailers will be passing by on a regular basis and possibly delivering a glancing blow.

Stelrad radiators are available from all quality builders and plumbers merchants and more information about the wide range of radiators they manufacture can be found on their excellent web site at www.stelrad.com. You can follow Stelrad on Twitter @Stelrad or on Facebook at www.facebook.com/StelradRadiators.

Click on the images to enlarge

View Stelrad's profile:

Armstrong Ceilings help Booths with a brand-new look

Story

Upmarket regional supermarket chain choose Armstrong’s metal and mineral ceilings for flagship store.

Upmarket regional supermarket chain choose Armstrong’s metal and mineral ceilings for flagship store.

Metal and mineral ceiling tiles from Armstrong were specified for a flagship supermarket for a multitude of reasons.

The dark grey Mesh Board metal tiles with Axiom Profile and grid in RAL 9007 feature in plasterboard margins in the lower sales area of the new £4.5million Booths supermarket in Lytham St Anne’s while Ultima+, the world’s first mineral tile range certified to Cradle to Cradle status, was used on the first-floor back-of-house areas.

The 3,210ft2 of Armstrong ceiling systems were specified to meet a tight timescale and to help with acoustics as well as to help the upmarket chain move away from more traditional ceiling designs and comply with new brand standards and guidance.

The 37,000ft2 “Heyhouses” project on a brownfield site in the genteel seaside town of Lytham St Anne’s in Lancashire took 20 months to complete. Built traditionally, the store features oak cladding to the internal steel frame and includes a café, butcher’s and cheese counters.

Armstrong’s 1200mm x 600mm metal Mesh tiles were installed by GWN Contracts and sit as rafts within variously shaped plasterboard margins. These were all laid on the diagonal to lead customers’ eyes through the 23,000ft2 main sales area to the state-of-the-art deli counter at the rear of the store.

Regular Armstrong specifiers Leach Rhodes Walker, who were the architects for the shell construction and internal fit-out, working alongside main contractor Interserve, have partnered with Booths supermarkets to develop café concepts for their stores.

LRW architectural technician Rebecca Kenny said: “The Ultima+ product was a standard product specified by Booths. The main sales area ceiling was in response to the new brand standards/guidance from Booths for a new approach to the ceilings. They wanted to move away from a lay-in ceiling and introduced a more industrial feel that also met the access requirement for the services above.

“As well as the access requirements the Ultima+ ceiling system help with the acoustic issues and the open mesh design also helped with the flexibility of the locations for the feature lighting.”

With regards to any special requirements or challenges, she added: “On the fit out, the time scale was an issue to meet the deadline to handover to Booths for their store fittings/merchandising works, also acoustics within the double-height spaces including the café, the ceiling design and approval to café interior design concept.”

The store opened in September 2015, creating 90 new jobs.

Rebecca added: “The client was very pleased with the overall appearance. It meets the original brief and as the mesh panels were combined with perimeter details, and plasterboard margins to help break up the large area, it created a really striking design feature.

“As Armstrong was already specified on the project it was really just looking through what they had available to meet the brief. It was always preferred to keep all the ceilings with one manufacturer. The ceiling is one of the most successful areas on the project, it was really well received. The fact that it was a proprietary product was particularly appealing.”

Armstrong area sales manager Claire Ombler said: “The finished product looks amazing and everyone is thrilled with the result. Graham Booth (Mr Booth himself) was said to be more than happy with the ceilings. This particular store is the flagship store for all the Booths stores hence it is great to hear that Graham Booth is very pleased with the look.”

View Armstrong's profile:

New Date for PICV CPD

Story

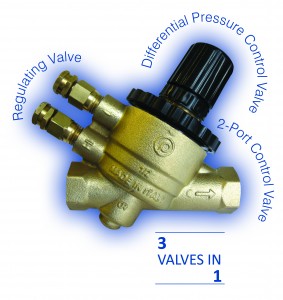

Marflow Hydronics has scheduled in a new date for its CPD training course on Pressure Independent Control Valves.

Marflow Hydronics has scheduled in a new date for its CPD training course on Pressure Independent Control Valves.

The CPD course is being held in Birmingham on 4th May and is free for anyone to attend. The half day session provides delegates with knowledge on how PICVs work, innovative pipe layouts and how to make systems more economical, including the introduction of electronic balancing. It’s aimed at consultants, designers, specifiers and key influencers who want to learn more about the products, improve their skills and specify, purchase or commission a PICV.

Nick Martin, Technical Manager at Marflow Hydronics, says, “PICVs are growing so much in popularity due to their numerous benefits, but to really get the best out of them then a user needs to fully understand them. Our course is set up to provide delegates with the knowledge they need to truly optimise the many advantages of the product.”

Places are limited, strictly on a first come first served basis, so immediate registration is recommended. To register or for more information visit www.marflowhydronics.co.uk/events, call 0121 358 2012 or email training@marflow.co.uk.

View Marflow Hydronics's profile:

NO MONKEYING AROUND WITH PUMPS AT CHESTER ZOO’S ISLANDS DEVELOPMENT

Story

Chester Zoo is one of the world’s leading zoos with around 1.6 million visitors every year. And with more than 20,000 animals, set in 125 acres of award winning zoological gardens, it’s not surprising that the visitors just keep coming back for more.

Chester Zoo is one of the world’s leading zoos with around 1.6 million visitors every year. And with more than 20,000 animals, set in 125 acres of award winning zoological gardens, it’s not surprising that the visitors just keep coming back for more.

To keep visitors amazed and entertained, the zoo has continuously invested in new attractions to showcase the animals to their best whilst maintaining its reputation for being a major force in conserving the living world. Step forward to the zoo’s latest attraction – Islands at Chester Zoo – a £40 million, 60,000 square metre development that aims to transport visitors to the South East Asian islands of Panay, Papua, Bali, Sumba, Sumatra and Sulawesi – it’s an inspired attempt and took over two years to build.

M&E Contractor for the development is Crown House Technologies – part of Laing O’Rourke – and they specified a wide range of pumps from leading pump manufacturer Wilo for the project. Overall in excess of £80,000 worth of pumps of various sizes and undertaking a range of roles have been installed to keep the new development running smoothly, providing a true South East Asian experience.

High efficiency pumps, cold water pressure booster sets and system pressurisation units have been utilised throughout the development to help keep animals as varied as Sumatran orangutans, Sulawesi crested macaques, Sumatran tigers and a huge range of rare reptiles including the Sunda gharial – one of the world’s largest crocodiles – warm and experiencing the levels of humidity that they would experience in their natural surroundings on the other side of the world. The humidifying air misting equipment powered by the Wilo pressure booster sets needs to be experienced to be believed and the Lazy River Boat Trip allows visitors to take a journey through the development and see the animals from the unique perspective of a boat, completing the jungle experience perfectly, in no small part due to Wilo’s pumps.

“It’s a privilege to have been involved in such a wonderful project,” says Wilo’s National Key Account Manager Peter Anthony. “We’ve worked closely on a number of successful projects with Crown House so it was good to be able to work alongside them again on a project of this importance. It’s a great example of just how important pumps are to every construction project – out of sight in plant rooms hidden across the project but providing the constant flow of water that the project requires to be successful.”

“It’s a privilege to have been involved in such a wonderful project,” says Wilo’s National Key Account Manager Peter Anthony. “We’ve worked closely on a number of successful projects with Crown House so it was good to be able to work alongside them again on a project of this importance. It’s a great example of just how important pumps are to every construction project – out of sight in plant rooms hidden across the project but providing the constant flow of water that the project requires to be successful.”

You can find out more about the full Wilo pump range and the solutions available at www.wilo.co.uk and more about Chester Zoo by visiting www.chesterzoo.org.