Category Archives: Energy

HIGH EFFICIENCY SMALL CIRCULATORS – Is ErP Legislation working?

Story

European legislation has its friends and its enemies as we have discovered, having survived the rigours of a recent General Election. Whatever the outcome of the promised referendum on EU membership here in the UK, we have to get on with abiding by European Directives for now. With many of the day to day products in use in the heating and plumbing sector being manufactured by European companies, it seems highly likely that with much of the legislation already in place and being acted upon, it would stay whatever the outcome. In the EU, or out, we clearly as a nation, need to reduce carbon emissions and continue to clean up our act on the environmental stage.

European legislation has its friends and its enemies as we have discovered, having survived the rigours of a recent General Election. Whatever the outcome of the promised referendum on EU membership here in the UK, we have to get on with abiding by European Directives for now. With many of the day to day products in use in the heating and plumbing sector being manufactured by European companies, it seems highly likely that with much of the legislation already in place and being acted upon, it would stay whatever the outcome. In the EU, or out, we clearly as a nation, need to reduce carbon emissions and continue to clean up our act on the environmental stage.

There is still a lack of realisation in some circles, of the amount of energy that is used day to day by pumps as a proportion of energy use in the average home. And every home pretty much, has one. Once understood, it’s easy to see why it was a prime area for attention when looking for ways of reducing energy use and reducing carbon emissions. In today’s vernacular, it was something of a ‘no brainer’.

Small circulating pumps are a key component of all wet heating systems in the UK – whether traditional boiler driven systems or new renewable systems. They perform as standalone pumps or as integrated pumps in combi and system boilers and they keep the water circulating in underfloor heating systems too. They are responsible for a much higher percentage of overall household electricity usage than many still realise which is why old uncontrolled pumps were targeted by European legislation as a key way of reducing energy usage in the home, reducing energy bills and reducing emissions. They offered a real way of making strides towards meeting the ambitious environmental targets set by the UK Government and European legislators.

Small circulating pumps are a key component of all wet heating systems in the UK – whether traditional boiler driven systems or new renewable systems. They perform as standalone pumps or as integrated pumps in combi and system boilers and they keep the water circulating in underfloor heating systems too. They are responsible for a much higher percentage of overall household electricity usage than many still realise which is why old uncontrolled pumps were targeted by European legislation as a key way of reducing energy usage in the home, reducing energy bills and reducing emissions. They offered a real way of making strides towards meeting the ambitious environmental targets set by the UK Government and European legislators.

Before January 2013, small circulating pump selection was often made on price. Although some installers had loyalty to a brand, in many people’s eyes, a pump was a pump was a pump. If it did the job, it did the job. There were a few high efficiency pumps on the shelves before the end of 2012, but at a far higher price than the standard efficiency ones. Until legislation said that you had to install them, despite some installers deciding that a high efficiency pump was what the customer deserved as part of an energy efficient heating system, from sales figures alone, it was clear that many were voting with their wallets.

From January 2013 high efficiency pumps were demanded by EU Legislation – the much vaunted ErP Legislation – and whilst there was initially some resistance to comply, as 2013 unfolded and availability of anything other than high efficiency options declined, installers began to buy and install and specifiers began to specify the high efficiency options. Now, just a few months down the line, high efficiency pumps have been accepted and are being installed in their thousands across the UK, with for example, some social housing landlords undertaking major pump replacement programmes, to help reduce their tenants’ electricity bills.

From January 2013 high efficiency pumps were demanded by EU Legislation – the much vaunted ErP Legislation – and whilst there was initially some resistance to comply, as 2013 unfolded and availability of anything other than high efficiency options declined, installers began to buy and install and specifiers began to specify the high efficiency options. Now, just a few months down the line, high efficiency pumps have been accepted and are being installed in their thousands across the UK, with for example, some social housing landlords undertaking major pump replacement programmes, to help reduce their tenants’ electricity bills.

Despite this embracing of the new legislation and availability of the new ErP compliant circulating pumps, the fact remains that there are still many millions of old, uncontrolled small circulators operating in heating systems across the UK. So there is still huge potential to further reduce energy use and energy bills in the months and years ahead. Wilo and other pump manufacturers have begun to see their high efficiency models begin to sell well. Helped by the legislation, there was little choice but to utilise the new high efficiency models.

Although the concept of lifecycle costs was not new in January 2013 when ErP came into force, it was a concept that had largely been associated with commercial projects rather than domestic ones. But suddenly it became more important and the additional costs that inevitably follow the development of exciting new technology – in this case the vastly improved electronics and the arrival of electronically commutated motors (ECMs) for small circulating pumps – were justified by the lower life cycle costs of the new high efficiency, more expensive pumps and the huge savings possible over a ten or fifteen year operational life time. These could pay for the increased capital cost of the pump at the outset, many times over.

Wilo has just announced it is celebrating the sale of 28 million small circulators in the past ten years. In addition the company recently celebrated the selection of its small circulators as the pumps in the new combi boilers launched by two major boiler manufacturers here in the UK. Wilo’s high efficiency small pumps – in particular the Wilo-Yonos PICO – have made a huge impact in the UK heating and air conditioning sector over the past two and a half years, since the arrival of the ErP legislation in January of 2013.

Wilo’s series of glandless pumps – Wilo-Yonos PICO, Wilo-Stratos PICO and Wilo-Stratos – are seeing increasing popularity across the board. They are relevant for nearly all applications for heating, air-conditioning and cooling in the building services area – from the family home to a small commercial or industrial building.

Sadly, as always, some people will try to circumnavigate new legislation and ignore the drivers for environmentally friendly products. There has been genuine concern in the pump industry about the on-going availability of non-ErP compliant pumps, and the mislabelling of some pumps being imported into the UK and European markets since January 2013. European manufacturers are concerned that these pumps, although cosmetically looking like the new high efficiency models, in some cases, do not meet the requirements of the ErP regulations. Wilo, along with fellow members of the British Pump Manufacturers Association, continues to monitor this situation and report breaches of the regulations to the relevant authorities.

In general terms, the arrival of the EU ErP Directive has clearly begun to make significant inroads in the energy consumption figures, and as a result the emissions figures. There’s a long way still to go to hit the targets being demanded. But the age of the energy efficient pump is very much here.

To find out more about Wilo’s highly convenient, reliable family of high efficiency, ErP compliant small circulating pumps, just click on to www.wilo.co.uk.

View Wilo's profile:

Klober airtightness accessories at the Building Centre

Story

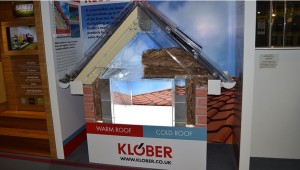

For those designing energy-efficient buildings, roofing specialist Klober now has a permanent exhibit at the Building Centre. Klober has pioneered the development of tapes, sealants, sealing collars and vapour control layers to seal the roof space, ceilings and tile penetrations. The company also manufactures high performance air-open and vapour permeable underlays for all roof types and pitch in order to provide balanced ventilation and airtightness. As with all exhibits at the Building Centre, brochures are available on site or via Specifinder – http://tinyurl.com/p4mjgmz. A roofing airtightness CPD presentation can also be booked by calling Ann Leeson on 01332 813060.

For those designing energy-efficient buildings, roofing specialist Klober now has a permanent exhibit at the Building Centre. Klober has pioneered the development of tapes, sealants, sealing collars and vapour control layers to seal the roof space, ceilings and tile penetrations. The company also manufactures high performance air-open and vapour permeable underlays for all roof types and pitch in order to provide balanced ventilation and airtightness. As with all exhibits at the Building Centre, brochures are available on site or via Specifinder – http://tinyurl.com/p4mjgmz. A roofing airtightness CPD presentation can also be booked by calling Ann Leeson on 01332 813060.

View Klober's profile:

WARMING TO STELRAD IN ARK PUTNEY ACADEMY

Story

Whilst Stelrad radiators are often associated with residential installations, increasingly they are being specified for commercial and public buildings where the quality of their manufacture and consequent longevity as part of an energy efficient heating system make huge sense. One major area where Stelrad radiators are making their mark is in educational buildings – schools, colleges and universities across the UK, where they work equally well with traditional boiler driven heating systems or modern renewable systems, ground source and air source heat pumps in particular.

Whilst Stelrad radiators are often associated with residential installations, increasingly they are being specified for commercial and public buildings where the quality of their manufacture and consequent longevity as part of an energy efficient heating system make huge sense. One major area where Stelrad radiators are making their mark is in educational buildings – schools, colleges and universities across the UK, where they work equally well with traditional boiler driven heating systems or modern renewable systems, ground source and air source heat pumps in particular.

Putney Academy in south west London, is one of 31 academies owned and managed by ARK in the UK. The organisation took over the former Elliott School in 2012 and has set about improving the quality of the buildings and their surroundings in a big way, such that the main buildings have been totally refurbished with high quality, modern school facilities that will hugely benefit the pupils attending the academy. The work will be completed by the time staff and pupils return to school after the summer holidays.

Part of the major refurbishment work at the academy has inevitably seen the provision of a brand new heating system to provide comfort and warmth in the colder months of the year. Both the UK’s leading low surface temperature range – perfect for a building with young people, offering safe heat from radiators where the surface temperature of the attractive casing never exceeds 43 degrees C – and a smaller number of Stelrad Planar designer, flat fronted radiators along with a selection of traditional Classic Column radiators were specified for the project.

Skelly & Couch are the building environment and services engineers for the project. Director Mark Maidment says: “We wanted quality radiators to complement the other components of the heating system but in particular wanted to use LST radiators in areas of the academy where youngsters congregate to ensure maximum safety. Stelrad’s leading range of LST radiators are easy to install and offer the maximum protection to the end user – the casings actually cover the pipework as well as the radiator itself so there are no ‘hot’ areas that could cause any problems. In addition, it’s vital the radiators used in a school environment are built to be robust and able to withstand and resist vandalism and day to day wear and tear. With those manufactured by Stelrad, the casing is held by security fittings that are quick and easy to install. The security fittings have a unique seam fixing bracket system that prevents unauthorised access to the emitter inside the casing.”

Skelly & Couch are the building environment and services engineers for the project. Director Mark Maidment says: “We wanted quality radiators to complement the other components of the heating system but in particular wanted to use LST radiators in areas of the academy where youngsters congregate to ensure maximum safety. Stelrad’s leading range of LST radiators are easy to install and offer the maximum protection to the end user – the casings actually cover the pipework as well as the radiator itself so there are no ‘hot’ areas that could cause any problems. In addition, it’s vital the radiators used in a school environment are built to be robust and able to withstand and resist vandalism and day to day wear and tear. With those manufactured by Stelrad, the casing is held by security fittings that are quick and easy to install. The security fittings have a unique seam fixing bracket system that prevents unauthorised access to the emitter inside the casing.”

“We were delighted that our radiators were specified for this project,” says Stelrad’s Chris Harvey. “We’re seeing a huge increase in the use of our radiators in commercial and public buildings. The use of LST radiators in schools makes huge sense from the point of view that they provide safe heat whatever environment they are installed in and they are protected from tampering by the way they are fixed to the wall, ensuring that the heating systems on-going performance is not compromised.”

Full details of the wide range of radiators available from Stelrad can be found at www.stelrad.com.

Click on images to enlarge:

View Stelrad's profile:

Passivhaus Certified Office, Syston

Story

The new regional office for Interserve Construction Ltd in Syston, Leicestershire features some of the most advanced green building solutions to achieve a targeted 90% reduction in energy usage and costs compared with a traditional building.

The new regional office for Interserve Construction Ltd in Syston, Leicestershire features some of the most advanced green building solutions to achieve a targeted 90% reduction in energy usage and costs compared with a traditional building.

27 windows and four doors from the GENEO® system were installed in the £1.5m, 680m² Passivhaus certified office, the majority of which were across its south facing aspect to increase solar gain in winter and minimise the requirement to generate additional heat. The 86mm REHAU GENEO® window is manufactured using the 100% recyclable RAUFIPRO® fibre composite material.

The inherent strength of this material enables the six chambered REHAU GENEO® system to perform without any requirement for steel in standard sized windows, eliminating the thermal bridges which can occur in conventionally reinforced PVC-U and which result in energy being lost.

View Rehau's profile:

Crittall’s stylish windows solution

Story

A prestigious headquarters building has been created within the stylish Harley Street Conservation Area in central London with the help of Crittall Corporate W20 windows both inside and out.

A prestigious headquarters building has been created within the stylish Harley Street Conservation Area in central London with the help of Crittall Corporate W20 windows both inside and out.

No. 116 Marylebone Lane, a four-storey 1930s building in the W1 area north of Wigmore Street, is owned by the Howard de Walden Estate and was previously in use as a Cordon Bleu cookery school.

Architects Morrow+Lorraine, who have particular expertise in the London commercial office, residential and retail sectors, were engaged to refurbish the building converting it from D1 non-residential use into a B2 self-contained Grade A office building.

A layout was chosen that maximises the floor to ceiling height with clear open floor plans yielding some 150 sq m on each of the four floors plus basement. The design provides for flexible space devoid of lobbies so as to aid free-flowing circulation.

‘The building frontage had been badly altered in the past and we wanted to recreate the elegance of the original façade which was achieved using a combination of glazed bricks, bespoke joinery and new steel windows,’ says director of Morrow +Lorraine Julian Morrow.

The project architect Peter Merrett takes up the story: ‘“We selected the Crittall Corporate W20 product to re-create the slim lines of the original 1930s glazing that needed to be replaced, whilst dramatically improving the thermal performance by incorporating double glazed units. The choice was largely driven by a desire to maintain the same pattern of glazing bars to preserve the character of the Marylebone Lane conservation area.”

The Crittall Corporate W20 units were employed front and rear in the refurbishment and the front elevation at ground floor level was reconfigured to reflect the original drawings from the architectural practice Forbes & Tate who designed the building in 1926-27.

The Crittall Corporate W20 units were employed front and rear in the refurbishment and the front elevation at ground floor level was reconfigured to reflect the original drawings from the architectural practice Forbes & Tate who designed the building in 1926-27.

Internally, the designers wished to reveal as much of the original fabric as possible. This was achieved by stripping back finishes and exposing the steel columns of the building’s structural frame. This emphasis on the use of steel was enhanced by the fenestration of the façade, a new steel staircase and the use of steel internal partitions.

‘We used the same Crittall Corporate W20 system to create single glazed screens which in turn allowed for a visual connection between the office space and the stair well, reception area and common parts, ‘ explains Peter Merrett. Referring to the W20 he adds: ‘The product is a design classic which fits seamlessly with our industrial, yet refined interiors.’ The inclusion of fire-rated and acoustic glazing also enhanced the technical performance of the Crittall Corporate W20 system.

The Crittall partition in the reception area acts as a muted backdrop to the focal point of the space, namely a bespoke polished concrete desk designed by Morrow+Lorraine and constructed by Lowinfo Design.

Project data

Location: 116, Marylebone Lane, London W1

Client: The Howard de Warden Estate

Architect: Morrow+Lorraine

Main contractor: Cameron Black and subsequently ARJ Construction

View Crittall's profile:

Wakaflex used as solar panel apron

Story

SolarWorld UK has begun to use Wakaflex to provide a watertight seal between its panels and the roof. Wakaflex can be used with either PV or solar thermal systems, its exceptional stretchability making it ideal for use with even deeply profiled tiles. Highly durable and available in four colours to blend with the roof covering, it can be stretched by up to 60%. A high-tack butylon backing not only provides immediate weatherproofing protection and wind uplift resistance but self-welds when used on laps.

SolarWorld UK has begun to use Wakaflex to provide a watertight seal between its panels and the roof. Wakaflex can be used with either PV or solar thermal systems, its exceptional stretchability making it ideal for use with even deeply profiled tiles. Highly durable and available in four colours to blend with the roof covering, it can be stretched by up to 60%. A high-tack butylon backing not only provides immediate weatherproofing protection and wind uplift resistance but self-welds when used on laps.

Click on image to enlarge:

View Haus Profi's profile:

NEW RADIATORS MEAN SAFE HEAT FOR SHELTERED SCHEME

Story

RESIDENTS IN PICTURESQUE SNOWDONIA

Leading radiator manufacturer Stelrad has supplied 155 of its sector leading low surface temperature radiators to provide safe and controllable heat in a refurbished sheltered apartments scheme – Cysgod y Coleg – in beautiful Bala – in the Snowdonia National Park in North Wales.

Leading radiator manufacturer Stelrad has supplied 155 of its sector leading low surface temperature radiators to provide safe and controllable heat in a refurbished sheltered apartments scheme – Cysgod y Coleg – in beautiful Bala – in the Snowdonia National Park in North Wales.

This scheme is just part of an overall £136 million refurbishment project being undertaken by Cartrefi Cymunedol Gwynedd – CCG – and highlights the level of investment the social housing provider is prepared to make in its extensive portfolio of social and sheltered housing across the region.

The work in Bala is being undertaken by main contractor Lovell Partnership, with the help of specialist plumbing and heating installers Aspect Plumbing & Heating. The selection of the Stelrad LST standard radiators was made by Engineering Design Services in Chester and these high quality radiators will be the means of sharing heat throughout the 28 apartments over two floors of this scheme and in the communal areas for residents use as well. The new heating system is driven by the latest condensing boilers and replaces an elderly and highly inefficient electric heating system that saw a large number of electric storage heaters throughout the premises.

LSTs are specially designed to provide comfortable heat, but in a radiator whose casing never exceeds 43 degrees centigrade. This makes them ‘safe to touch’. LST radiators are key where there is a need for special heat emitters that are ideal for safety critical environments – especially those that need to meet NHS Guidance for ‘Safe Hot Water and surface temperature’ – in hospitals, care and nursing homes, doctors and dentists surgeries as well as schools, nurseries and as in this case – sheltered accommodation. It’s a specification requirement of building designers and architects that the heat emitters in these buildings protect the young, the elderly and the vulnerable, who will live in or visit buildings such as these.

LSTs are specially designed to provide comfortable heat, but in a radiator whose casing never exceeds 43 degrees centigrade. This makes them ‘safe to touch’. LST radiators are key where there is a need for special heat emitters that are ideal for safety critical environments – especially those that need to meet NHS Guidance for ‘Safe Hot Water and surface temperature’ – in hospitals, care and nursing homes, doctors and dentists surgeries as well as schools, nurseries and as in this case – sheltered accommodation. It’s a specification requirement of building designers and architects that the heat emitters in these buildings protect the young, the elderly and the vulnerable, who will live in or visit buildings such as these.

LST radiators negate the risk of in particular, older people falling and injuring themselves on a radiator along with potential dangers from those with a visual impairment bumping into or brushing against radiators. Some elderly people have a reduced sensitivity to high temperatures and others simply cannot react quickly enough to prevent injury from hot surfaces if they inadvertently touch and come into contact with a conventional radiator, where surface temperatures may be as high as 75°C. Older people and those suffering injuries have an increased susceptibility to losing their balance and falling, and the possibility of these people falling and becoming trapped against a conventional radiator brings the need for LST radiators sharply into focus. With Stelrad LST radiators, the casing also covers the incoming pipework making sure all the heated surfaces are concealed and that any exposed surfaces stay at a safe temperature of no more than 43°C.

“These LST radiators are simple to fit and offer quality heat emitters that are controllable and effective in a building such as this,” says Phil Houghton from Aspect Plumbing and Heating. “We have fitted these for many years and were happy to find they were specified by the architects for this job.”

“The safety and comfort of our tenants is the key consideration for us,” says Steve Williams, Contract Co-ordinator for CCG. “When looking at the refurbishment of Cysgod y Coleg, it was clear that these low surface temperature radiators were the answer for the apartments, the corridors and the extensive communal lounge areas within the newly revamped building. The new radiators combined with the condensing boilers, high levels of insulation and the new, precise heating controls installed will see far more effective heating and a much more cost effective heating system than the old building had. It’s a major investment but one that will pay back relatively quickly for us in lower energy bills.”

“We’re delighted that our LST radiators were selected for this particular sheltered scheme in Bala,” says Stelrad’s Marketing Communications Manager Sarah Baker. “Our LST range is the most popular range in the UK and contributes to the safety and comfort of huge numbers of elderly, young and vulnerable people in the country. Low surface temperature radiators are clearly a highly effective way of guarding hot surfaces and eliminating the dangers of burning people who are in the vicinity, whether in their homes or in a public building.”

Full details of the Stelrad LST range can be found on www.stelrad.com, you can call for brochures and information on 0844 543 6200 or email marketing@stelrad.com . You can follow Stelrad on Twitter @Stelrad or on Facebook at www.facebook.com/StelradRadiators.

View Stelrad's profile:

“The Most Sustainable HVAC System in the World”

Story

Mike Nankivell, marketing director for the UK Daikin Distributor, Space Air Conditioning plc, comments on the latest VRV development from Daikin Europe.

Mike Nankivell, marketing director for the UK Daikin Distributor, Space Air Conditioning plc, comments on the latest VRV development from Daikin Europe.

“The VRV IV heat recovery system makes huge advances in climate control efficiency. Not only is it up to 28% more efficient than the previous generation of VRV, it is more flexible and can be installed faster than any other heat recovery system available.”

“Daikin’s VRV IV heat recovery system is able to integrate heating, cooling, ventilation and hot water, recovering “free” heat from areas requiring cooling and using it to heat other areas and provide hot water. Daikin Europe calls it “The most Sustainable HVAC System in the World”.

Focus on Efficiency

Daikin Europe’s three-pipe VRV heat recovery systems were already considered the most energy efficient on the market but VRV’s fourth generation features important new innovations outlined below, which “fine tune” the focus on efficiency with remarkable results:

1. Variable Refrigerant Temperature technology

2. Continuous heating during defrost

3. The VRV configurator

1. Variable Refrigerant Temperature technology enables the refrigerant temperature to be adjusted to match heating or cooling demand and the outside temperature, reduced power consumption results in an improved operating efficiency of as much as 28%. Comfort is also enhanced because variable refrigerant technology enables cold draughts to be avoided,

2. The defrost cycle can result in reduced indoor temperatures at a time when this is undesirable. VRV IV’s continuous heating during defrost avoids this issue and maintains comfort levels when the defrost cycle is activated.

3. The VRV configurator software enables the system to be “set up” off site, saved to a USB and simply uploaded at the commissioning stage. This feature greatly simplifies both the installation and commissioning of Daikin VRV systems.

New Multi-Port BS Boxes

Daikin’s VRV systems are renowned for being the most flexible available. Modular by design, VRV be adapted to fit any can size of building and reconfigured easily if internal layouts change over time. To enhance this flexibility even further, Daikin has introduced new multi-port BS boxes. The new multi-port BS boxes have up to 16 ports and are the lightest and most compact on the market. These can greatly reduce installation times compared with installing single BS boxes. To complete the new VRV package, Daikin Europe’s Intelligent Touch Manager offers comprehensive climate control and mini BMS facilities whilst also being able to link with third party systems.”

Concluding Mike Nankivell observed. “As one of the oldest of Daikin Europe’s network of independent distributors, Space Air is accustomed to the continuous development of Daikin products, yet even we were impressed with the improvements that have been achieved with VRV IV. We are also delighted to see the key 4th generation features being extended to the entire VRV portfolio at a time when operating efficiency is recognised as a critical factor in reducing the carbon footprint of our air conditioned buildings.”

For more information please call Marketing on 0333 0069 755 or email marketing@spaceair.co.uk.

View Space Air's profile:

U1000 HM – Fixed clamp-on Heat/Energy metering solution

Story

Clamp-on to a New smarter clamp-on solution to heat/energy metering from Micronics for significant installation savings and simple, accurate measurement from outside the pipe!

Measuring the heat/energy consumption of hot (LTHW) and chilled water services to monitor, control and manage energy consumption is a key area in building services and energy management. But the installation process including system drain down, pipe cutting etc has always been a significant cost and barrier to wider application of sub-metering. At last a solution has arrived from the longest established manufacturer of clamp-on, ultrasonic meters the U1000 HM heat/energy meter from Micronics. Building on their many years of experience and success in this area, Micronics has now developed a best value clamp-on heat/energy meter to compliment its successful U1000 clamp-on flow meter and facilitate the wider use of clamp-on ultrasonic flow measurement for water sub-metering and heat/energy measurement.

Measuring the heat/energy consumption of hot (LTHW) and chilled water services to monitor, control and manage energy consumption is a key area in building services and energy management. But the installation process including system drain down, pipe cutting etc has always been a significant cost and barrier to wider application of sub-metering. At last a solution has arrived from the longest established manufacturer of clamp-on, ultrasonic meters the U1000 HM heat/energy meter from Micronics. Building on their many years of experience and success in this area, Micronics has now developed a best value clamp-on heat/energy meter to compliment its successful U1000 clamp-on flow meter and facilitate the wider use of clamp-on ultrasonic flow measurement for water sub-metering and heat/energy measurement.

The U1000 HM is a simple out of the box, onto the pipe heat/energy metering solution with no programming or specialist engineering required! All you have to do is clamp the unit to the pipe, select the pipe size, release the sensor clamps, secure the pre-wired, clamp-on PT100 flow and return temperature sensors and connect power to the pre-wired cable provided. Yes it really is that simple because Micronics have listened and simple installation is a key design feature. Another cost-effective alternative to expensive in-line meter installation from Micronics with no drain down or cutting of pipes required plus dry servicing, providing minimum downtime and maximum availability!

The U1000 HM is a clamp-on, transit time, ultrasonic flow meter plus PT100 temperature sensors designed to provide accurate measurement of liquid flowing within a closed pipe plus the flow and return temperature difference to calculate the heat/energy load, without the need for any mechanical parts to be inserted through the pipe wall or to protrude into the flow system. It takes just a few minutes to install and there is no need to shut down flow or drain the system! And its Modbus compatible, so it can be used as a standalone meter or an integrated part of your aM&T or BEM’s system.

So if you need to meter the heat/energy load of hot (LTHW) or chilled water services as part of your energy management strategy or building services, for retrofit or new build applications, the U1000 HM should be a must consider solution! For further information call: +44 (0)1628 810456 or visit www.micronicsflowmeters.com

View Micronics's profile:

Klober air-open underlay for highest performance

Story

With a water vapour resistance of 0.03 MN/sg, Klober Permo® air is approved by the NHBC for use without supporting high level ventilation. The BBA-certified, air-open underlay has consistently proved to be the most breathable membrane available and prevents formation of condensation in the roof space during a building’s critical drying out period. Permo air has also been independently tested for wind uplift by the BRE which found it to be suitable for use up to Zone 5 on the recently introduced BS 5534 wind speed map (with laps taped or battened in zones 4 and 5).

With a water vapour resistance of 0.03 MN/sg, Klober Permo® air is approved by the NHBC for use without supporting high level ventilation. The BBA-certified, air-open underlay has consistently proved to be the most breathable membrane available and prevents formation of condensation in the roof space during a building’s critical drying out period. Permo air has also been independently tested for wind uplift by the BRE which found it to be suitable for use up to Zone 5 on the recently introduced BS 5534 wind speed map (with laps taped or battened in zones 4 and 5).