Category Archives: Energy

Are you receiving complaints about leaks and blockages from residents? View this video from Saint-Gobain PAM Building to see how they could help you to find a way forward.

Story

Are you receiving complaints about leaks and blockages from residents? It could be that your drainage system is faulty or nearing the end of its life. We will provide a condition report, findings, and recommendations for how we could go forward.

For more information, visit: https://www.pambuilding.co.uk/stack-replacement.

View PAM Building's profile:

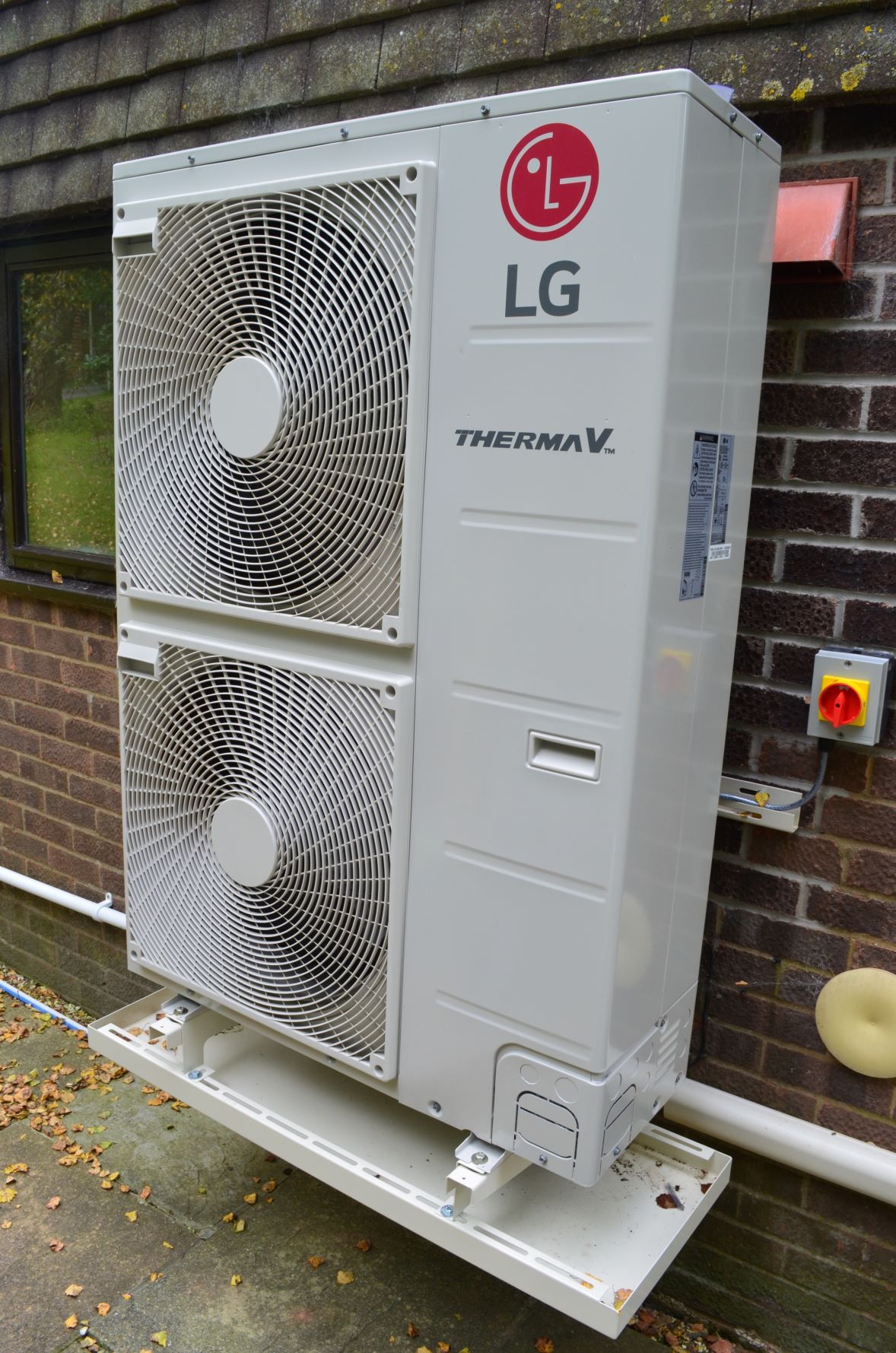

HVAC specialist LG helps us to find out more about the latest Therma V R32 Monobloc S air source heat pump

Story

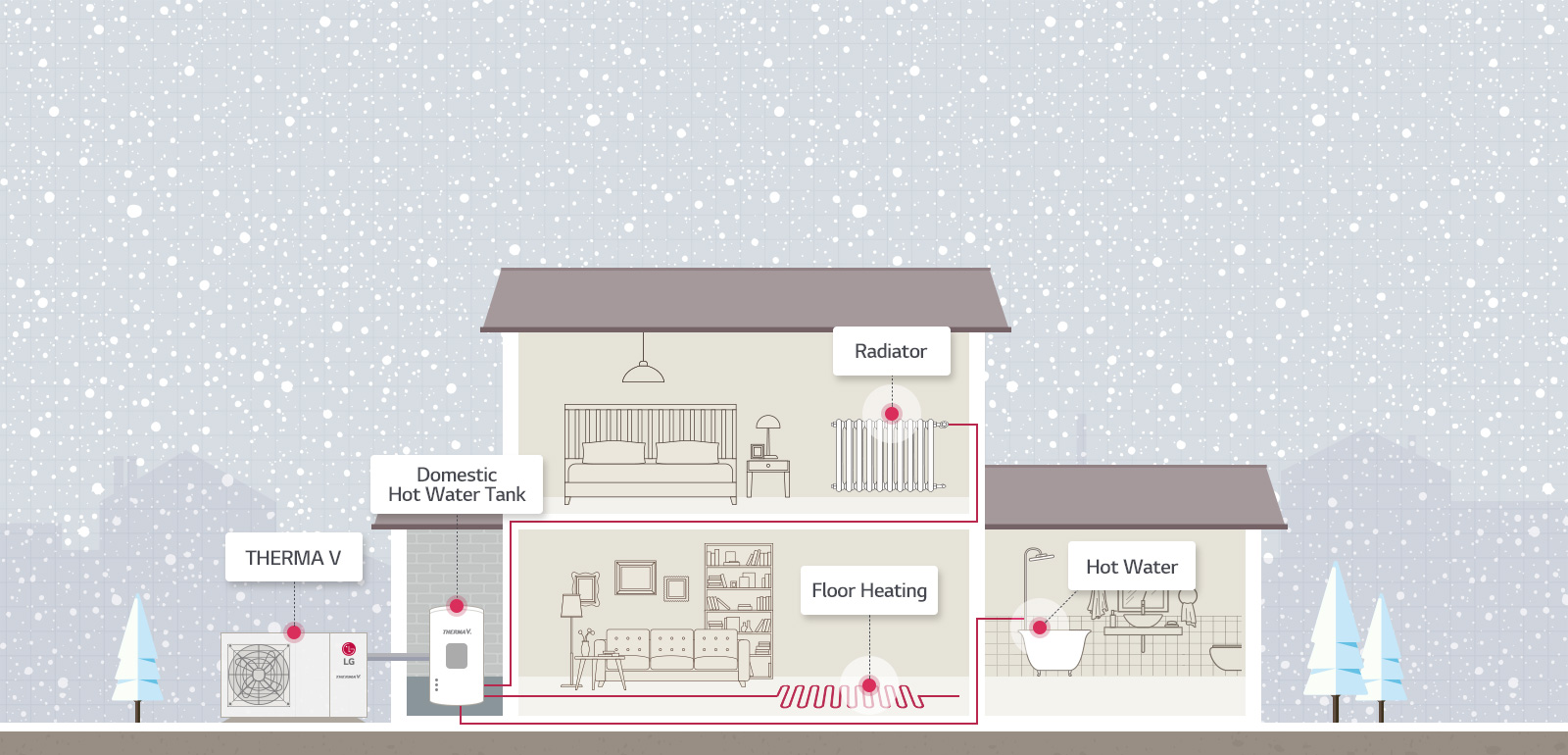

With many in the sector considering Heat Pumps, BNE spoke with Neil Hopkinson, National Heating Sales Distribution Manager from HVAC specialist LG to find out more about the company’s latest Therma V R32 Monobloc S air source heat pump.

Q. How efficient is an Air Source Heat Pump (ASHP)?

Today’s Air to Water Heat Pump (AWHP) systems – monoblocs or splits – are hugely energy efficient when you compare them to traditional fossil fuel driven heating systems. The highest efficiency boiler you can buy is something like 95% efficient. An AWHP like LG’s new Monobloc has a seasonal coefficient of performance of up to 4.67 and an A+++ rating – and presents a variety of energy-saving options for a home’s heating and hot water system. By replacing a traditional gas, oil, or solid fuel system, an AWHP can significantly reduce carbon emissions and energy usage. These device’s absorption of natural energy from external air makes them consume less energy than conventional heating systems. And they can operate successfully at low temperatures – the LG Therma V range has 100% capacity at temperatures as low as -7°C – and it’s very rare for temperatures in the UK to go that low even for a day each year.

Q. What is the difference between a Monobloc and a split system? And how does a monobloc work?

The terms ‘Split’ and ‘Monobloc’ refer to how the system is required to be set up in a home. A Monobloc is a bit like a combi boiler and is literally a ‘single block’ system, where the heat pump has all of its  components – apart from the hot water cylinder which is installed inside the property – located inside a heat pump unit situated outside the home. Because a monobloc does not require someone with F Gas qualifications to get involved in the use of refrigerants, they are an excellent additional string to the bow of most professional heating installers who after attending a relevant training course will be well placed to join the growing band of installers that will be required to swell the numbers of people capable of installing these excellent heating systems here in our home market.

components – apart from the hot water cylinder which is installed inside the property – located inside a heat pump unit situated outside the home. Because a monobloc does not require someone with F Gas qualifications to get involved in the use of refrigerants, they are an excellent additional string to the bow of most professional heating installers who after attending a relevant training course will be well placed to join the growing band of installers that will be required to swell the numbers of people capable of installing these excellent heating systems here in our home market.

A Split heat pump unit has both an outside unit which incorporates the heat exchanger and refrigerant and an internal unit which sits inside the property, usually in a utility or boiler room.

Most homes in the UK are ideal for a Monobloc air to water heat pump but some will require upgrades to their level of insulation. A Split system is an option generally for more complex installations and it can be installed up to 50m away from the home, which gives far more installation flexibility.

Q. Do installers need an F-gas qualification to fit ASHPs?

Installers only need an F-Gas qualification if they are installing equipment that requires them to work with refrigerants. This is the joy of installing monobloc systems where the system comes ready primed with the refrigerant – in the case of the LG Therma V Monobloc it’s R32, which has a low Global Warming Potential of just 675 – 70% lower than R410A which was widely used in recent years. With monoblocs like the LG one, the only pipework to install is the water pipe between the external unit and the internal hot water tank.

Q. What are the features on the new Therma V R32 Monobloc S?

The original LG Therma V Monobloc has already seen enormous success in the UK marketplace as heat pump sales in 2021 trebled over sales in the previous year. But this new ‘S’ version is set to make unparalleled sales figures in 2022 as more and more housebuilders and developers, local authorities and social housing providers move to use renewable options in their new build homes and begin the process of replacing older and inefficient gas boilers with an option that future proofs their existing homes in the years ahead.

This new model combines the indoor and outdoor features in one module. Hydronic components like the improved plate heat exchanger, the expansion tank, water pump, flow sensor, pressure sensor, air vent valve and safety valve are all built in – inside the outdoor unit – pre-installed and ready to run. And the R32 Monobloc ‘S’ provides excellent heating performance especially at low ambient temperatures whilst lowering its carbon emissions even more with the use of R32.

The innovative design and technology in this new unit sees built in water flow and pressure sensors to monitor the water circuit in real time, advanced water pump control, enhanced second circuit logic, energy monitoring of estimated power consumption via the remote controller and advanced control for the domestic hot water recirculation pump.

The innovative design and technology in this new unit sees built in water flow and pressure sensors to monitor the water circuit in real time, advanced water pump control, enhanced second circuit logic, energy monitoring of estimated power consumption via the remote controller and advanced control for the domestic hot water recirculation pump.

Installers will love the new Monobloc ‘S’ – the all-in-one concept and reduced weight of the unit makes for easier and quicker installations. The new version requires lower amounts of refrigerant compared to the existing model – 16.7% less in fact – reducing emissions and lessening its environmental impact still further. The new version features LG’s revolutionary R1 Compressor technology which offers advanced efficiency, reliability and operational range due in part to the enhanced tilting motion of the scroll. It offers enhanced operational range – up to 135Hz, a shaft-through structure and support at both ends of the shaft which ensures higher durability and offers bottom compression and simple structure that offers lower noise and vibration, less weight and superior reliability.

Within the outdoor unit the new version of the LG Monobloc offers a new compressor noise shield, a new Black Fin coated heat exchanger, a new water flow sensor and a new water pressure sensor.

The unit comes with a Seasonal Coefficient of Performance of up to 4.67 (Average climate/Low temperature application) and a A+++ rating. The COP rises to 4.9 (Outdoor air 7°C/Leaving water temperature 35°C) and can deliver leaving water temperature of 65°C if required.

Q. One concern relating to ASHPs is the level of noise they emit. How has LG tackled this issue?

How has LG tackled this issue?

This is a bit of a red herring today. ASHPs are in general very quiet and do not cause any issues for owners or their neighbours. The original LG Therma V Monobloc version was extremely quiet, but the new ‘S’ version is even quieter and up to 9kW units can be installed at the minimum of 4 metres away, and up to 16kW units – up to 5 metres away from neighbouring houses complying with international noise regulations.

Q. What controls can be used with the Therma V R32 Monobloc S?

LG equipment is justly renowned in the industry for its controllers and the new Monobloc ‘S’ is equipped with a new advanced remote controller which supports a number of functions. It comes with a premium design 4.3-inch colour LCD monitor, user friendly interface that uses simple graphic, icon and text controls, easy schedule and installer settings and energy monitoring without meter interface to provide estimated power consumption figures. It is possible to monitor not only the temperature of the water circuit but also the flow rate and the pressure. This information provides installers with more reliable information for installation and maintenance.

View LG's profile:

STELRAD GROWS THE BUSINESS AND OFFERS MORE…

Story

The UK’s no.1 radiator manufacturer, Stelrad has agreed to buy DL Radiators srl from De Longhi Industrial SA. DL Radiators’ main manufacturing site is located in Moimacco, near Udine, Italy and It currently employs around 350 people. Stelrad said it will buy DL Radiators for EUR28.3 million.

Stelrad said that the purchase builds on its acquisition policy and strategy. DL Radiators will extend the range of radiators available to its existing sales and distribution network, expand its routes to market, provide a complementary brand and increase its manufacturing capacity.

strategy. DL Radiators will extend the range of radiators available to its existing sales and distribution network, expand its routes to market, provide a complementary brand and increase its manufacturing capacity.

DL Radiators’ management team, led by Chief Executive Stefano Valente, will continue to run the business with Stelrad’s oversight.

Stelrad Group Chief Executive Trevor Harvey said: “Following completion of this transaction, Stelrad will be a market leader in six countries and hold a top three position in five more. We will continue to develop our mainland European relationships with the long-established regional distribution players in those territories, ensuring we continue to adapt to evolving routes to market.”

This acquisition highlights the importance of offering a wide range of radiator solutions at a variety of price points and shows the importance for UK manufacturing of maintaining a healthy trading relationship with mainland Europe.

Here in the UK the changing nature of the heating sector is seeing companies like Stelrad needing to adjust to the new requirements of the heating sector, in particular to meet the demands of the new renewable heating systems that are becoming ever more popular. The rise and rise of the heat pump marketplace is seeing the need for larger and higher capacity radiators and Stelrad has responded to these needs by broadening its already massive range of sizes and shapes for its most popular radiators and the introduction of in particular, a wider range of vertical radiators and is meeting the enhanced need for its K3 radiators – with three panels and three fins offering 50% more heating capacity from a radiator with the same footprint as a K2 format radiator for example.

Stelrad continues to mount its ‘Fit for the Future’ campaign, highlighting that despite what you might see and read, radiators are very much able to provide the levels of comfort heating and hot water required in UK homes, when paired with heat pumps.

Stelrad continues to mount its ‘Fit for the Future’ campaign, highlighting that despite what you might see and read, radiators are very much able to provide the levels of comfort heating and hot water required in UK homes, when paired with heat pumps.

The arrival of the low temperature heating system has brought with it perhaps understandable questions that specifiers, architects and house builders want answers to. Can we still use products we use now with traditional boiler driven heating systems if the heat source is a heat pump? Is there anything we need to consider that we take for granted nowadays? The answer is of course yes – we need to look closely at how to ensure that the heat generated is shared effectively in the new home or the existing home that is having its heating system upgraded.

But it’s important to sift the information currently being put about out there and look at the facts rather than the perhaps glib statements being made by some companies in the attempt to boost the sales of their own products. It’s important to look for the facts about the use of their own products rather than the sometimes misleading myths about the products offered by their competitors.

The development of lower temperature heating systems, utilising renewable heating appliances such as air source heat pumps – has given rise to a number of questions including where do components we have got to know and love over the years fit into the future of heating? Stelrad Radiators has responded forcefully to those companies who claim for example that underfloor heating is the only or ‘best solution’ for heat pump installations.

More than 90% of all heating systems in the UK currently rely on radiators to share the heat around the home. In new build housing, using a heat pump-based solution is a relatively simple solution. The heating system can be designed into the home at the outset so you know the parameters in which the heating system has to operate – the method of construction, the size of the rooms, the number, type and size of doors and windows – so the heat loss calculations can be done up front and radiators sized accordingly. The levels of insulation can be agreed at the outset that will provide the best support for any heating system chosen, whether radiators or UFH. The key to radiators operating well in any situation is to size them properly at the outset, which involves accurately working out heat loss calculations to achieve the necessary number of BTUs required to provide comfort heating in each room and to select a radiator that can provide that level of heating.

radiators to share the heat around the home. In new build housing, using a heat pump-based solution is a relatively simple solution. The heating system can be designed into the home at the outset so you know the parameters in which the heating system has to operate – the method of construction, the size of the rooms, the number, type and size of doors and windows – so the heat loss calculations can be done up front and radiators sized accordingly. The levels of insulation can be agreed at the outset that will provide the best support for any heating system chosen, whether radiators or UFH. The key to radiators operating well in any situation is to size them properly at the outset, which involves accurately working out heat loss calculations to achieve the necessary number of BTUs required to provide comfort heating in each room and to select a radiator that can provide that level of heating.

Stelrad offers a simple to use and free radiator sizing and heat loss calculator along with a Renewables Advice page on its website. Facts and helpful information are also shared through a free to take CPD also available on its website, to anyone – not myths and misleading statements.

In replacement heating systems for older properties there are of course additional issues. It’s a fact that simply replacing a boiler with a heat pump will usually see the existing radiators unable to provide the levels of heat needed in a home. So what is the solution? One that is cost effective and straightforward? Do we need to ditch radiators altogether and look for alternatives?

The simple answer is no. Radiators will work well with heat pumps, but you will need to increase the size of the radiators to provide a larger metal surface area to heat the air in the room to the level required to provide comfort heating. This need not involve unsightly radiators – for one, modern radiators are aesthetically far more attractive anyway, but there are other solutions too. You can achieve the extra boost radiators need by replacing the existing single or double panel radiators with the relatively new K3 radiators that have three panels and three sets of fins – providing the additional metal surfaces you need but without increasing the radiator footprint on the wall.

The arrival of the new upgrade to Building Regulations with effect from 15th June in England and from November this year in Wales brings with it a realisation that the key figure to bear in mind is 55°C – the maximum flow temperature for all new wet heating systems from this date. The regulations also say that heating appliances and radiators should not be oversized. TRVs need to be fitted to every radiator except where there is a room thermostat fitted. The differential between the flow and return should be 10°C – giving a 45°C return, and a mean water temperature of 50°C. This will have an impact on radiators but simply means that sizing of radiators is more important than ever and Stelrad is offering all the advice you could need through their website to point installers and specifiers in the right direction with regard to using the right radiators in the right applications.

The arrival of the new upgrade to Building Regulations with effect from 15th June in England and from November this year in Wales brings with it a realisation that the key figure to bear in mind is 55°C – the maximum flow temperature for all new wet heating systems from this date. The regulations also say that heating appliances and radiators should not be oversized. TRVs need to be fitted to every radiator except where there is a room thermostat fitted. The differential between the flow and return should be 10°C – giving a 45°C return, and a mean water temperature of 50°C. This will have an impact on radiators but simply means that sizing of radiators is more important than ever and Stelrad is offering all the advice you could need through their website to point installers and specifiers in the right direction with regard to using the right radiators in the right applications.

Major radiator manufacturers such as Stelrad have anticipated the significant move towards air source heat pumps in the UK and have added new, larger size radiators to their portfolio providing that option. They have also stepped up the options on the K3 radiator designs available too. In addition, the huge popularity of vertical radiators has also offered a solution. Vertical radiators clearly have a smaller horizontal footprint than a traditional radiator, but they can be larger by design – taking up floor to ceiling space. It may be more practical and more attractive to have two modern vertical radiators in a room than one large standard radiator which traditionally has been placed along under the main window.

Stelrad has developed a wider range of vertical radiators, adding a huge number of new designs and sizes helping to provide the larger radiators needed by the renewable heating options. So new low temperature heating systems offer additional opportunities for the products we know and love and have used virtually every day of our working lives, for years. There’s no need to change what we do, just an element of changing how we do it and the questions we ask when undertaking an installation or specifying for a heating system design.

Radiators are very much ‘fit for the future’ but as always, correct sizing will need to be undertaken to ensure that they keep the home warm and cosy. But can radiators work well with air source heat pumps? Very definitely yes they can – and they already are in a host of installations across the UK.

View Stelrad's profile:

Saint-Gobain PAM Building pre-assembled solutions save you up to 60% of your time on-site

Story

Not only will our pre-assembled solutions save you up to 60% of your time on-site. Our stillages are also specifically designed for one-person handling allowing ease of movement around the site and halving the labour costs for installation.

Want to find out more? Visit: https://lnkd.in/e_WF5p2K

View PAM Building's profile:

Learn why Saint-Gobain PAM UK PAMREX covers are an ideal solution in areas of surcharge on city roads that are heavily trafficked

Story

With the warnings of increased rainfall this winter and localised flooding becoming more and more prevalent, the PAMREX is an ideal solution in areas of surcharge on city roads that are heavily trafficked – Pamrex covers act like a clamshell, removing the surface water easily and effectively. Watch the video to learn more.

View Saint-Gobain PAM UK's profile:

PODCAST – IMPROVING FOOD PRODUCTIVITY WITH HUMIDITY

Story

Humidity control specialist, Condair, has released a new podcast about how food manufacturers can enhance their productivity by controlling their production area’s humidity.

In a 10-minute interview with BusinessNet Explorer, Dave Marshall-George, Sales Director at Condair, explains how paying more attention to a manufacturing or storage area’s ambient humidity, can improve manufacturing yield and profits.

Dave explains, “Accurate humidity management in food and beverage production has many benefits. There are a huge range of applications. Humidification is frequently used to reduce evaporative losses, prevent static issues and extend shelf-life of produce. Dehumidification can be employed to more efficiently dry a product, eliminate condensation, reduce cold storage overheads or prevent products sticking to conveyors.

“As a humidity control specialist, we work with food and beverage manufacturers to identify areas of potential improvement across a production line, and then implement systems to maintain the ideal environment to realise those benefits. For example, we work in the meat sector to reduce evaporative losses from carcasses during primary chilling, with cheese manufacturers to reduce weight losses during cheese ripening, with bakers to optimise proving and oven baking, and distilleries and wine makers to prevent evaporation through casks.”

In this podcast Dave provides an overview of the potential for productivity improvements in a variety of applications and offers advice on how manufacturers might takes steps to start improving their processes. “Properly understanding the environmental profile of an area is key.” Dave continues, “This isn’t just an average temperature and humidity level in a room. It can include the micro-climate directly next to the product and being aware of any temperature differences between product and atmosphere. If a product is cooler than the air, this can lead to condensation, and if it’s warmer than the air, to moisture loss through evaporation.

“Using multiple data loggers is a good idea to properly assess the atmospheric profile of an area. However, for any manufacturer interested in exploring how they might improve profits through improved humidity control, I’d recommend having a free site assessment from their local Condair sales engineer. We offer free on-site reviews and are always happy to talk to food and beverage manufacturers about possible improvements they can make.” Dave concludes.

The podcast is available on Spotify, Google Podcasts, Soundcloud and Apple iTunes by searching for “Condair Podcast”, or on the Condair.co.uk website.

The Condair Group is the world’s leading specialist in humidity control and evaporative cooling, with energy efficient, hygienic and innovative technologies for commercial, industrial and heritage applications. Condair is represented in the UK by Condair Limited, which offers system design, manufacture, supply, installation, commissioning, maintenance and spares. You can find out more by visiting the company’s website at www.condair.co.uk.

View Condair's profile:

NEW HR MANAGER AT CONDAIR

Story

Humidity control specialist, Condair, has appointed Louise Kelly as its new HR Manager. Louise brings a wealth of experience to Condair having previously worked in HR roles at The Body Shop, Catalina Re and The Hartford.

Tony Fleming, Head of Sales Cluster Northern Europe at Condair, commented, “As an organisation, Condair has always been very focused on supporting and developing its team, and providing a happy and fulfilling place to work. It’s because of this that I am so delighted to welcome Louise on-board. Having worked with such progressive companies before, we feel very lucky to have her join Condair.”

Louise commented, “I’m greatly looking forward to getting to know the people at Condair and continuing to support and develop a working environment that is collaborative, challenging, motivating and rewarding for all of our employees. With more than half of our employees having been at the company for at least 10 years, it’s evident that Condair greatly values the importance of investing in and developing people. This talent and experience really shines through in the expertise and services the company provides”.

The Condair Group is the world’s leading specialist in humidity control and evaporative cooling, with energy efficient, hygienic and innovative technologies for commercial, industrial and heritage applications. Condair is represented in the UK by Condair Ltd, which offers system design, manufacture, supply, installation, commissioning, maintenance and spares. You can find out more by visiting the company’s website at www.condair.co.uk.

View Condair's profile:

Profab Access sets the standard for specification at Sixty London Wall

Story

Located within the epicentre of central London, Sixty London Wall delivers high quality Grade A office accommodation combined with superior retail opportunities, all housed within a visually striking contemporary development that stands apart from neighbouring buildings.

Delivering 325,000 sq. ft of premium office space over 10 floors, the extensively renovated property offers collaborative working areas, bolstered by first class end of journey facilities for commuters, including 380 cycle spaces and lockers and 38 showers and changing rooms.

Delivering 325,000 sq. ft of premium office space over 10 floors, the extensively renovated property offers collaborative working areas, bolstered by first class end of journey facilities for commuters, including 380 cycle spaces and lockers and 38 showers and changing rooms.

As part of the construction process, almost 500 Profab Access high quality riser doors and access panels have been installed throughout the entire building by specialist carpentry, joinery and fit-out contractors, JJ Sweeney.

Specified in a range of sizes and configurations for installation throughout the communal areas and washrooms on every floor, Profab Access’ robust and resilient INTEGRA 4000 Series and VISION 8000 Series fire-rated Riser Doors provide concealed access to mechanical and electrical services.

The steel riser doors offer the ability to seamlessly integrate into masonry walls, shaft walls and drywall partitions, providing the highest standards in functionality and safety, whilst simultaneously enhancing the overall interior aesthetic.

The construction of the new mixed-used development, which was managed by Skanska, spans 1.25 acres, offering 30% more floor accommodation than the previous structure, with all internal walls removed and a new atrium constructed through the centre of the building. Five standout walkable sky gardens that span 21,089 sq. ft also take pride of place across the building’s exterior, offering unobstructed views of the capital’s most iconic landmarks.

Due to the prime city centre location of the development, it was essential Sixty London Wall offered professionals the highest quality end of journey facilities, with dedicated ground floor showering and changing facilities, combined with washrooms on every floor.

Due to the prime city centre location of the development, it was essential Sixty London Wall offered professionals the highest quality end of journey facilities, with dedicated ground floor showering and changing facilities, combined with washrooms on every floor.

Profab Access’ VISION 8000 Series Riser Doors were specified for installation throughout each of these areas due to their unique construction providing complete design freedom, offering the ability for bespoke facades to be created to complement the chosen interior design scheme.

During the fit out process, the facade of each of the VISION 8000 Series Riser Doors were clad in the same ceramic tiles as those on the surrounding walls, successfully disguising each panel to create a flawless, concealed, high quality finish that supported, rather than impacted, on the chosen visual style.

Whilst aesthetics was a leading consideration throughout the specification process, the fire performance and functionality of the riser doors were also important factors. Regardless of the stone material installed onto the facade of the VISION 8000 Series, it will still retain its impressive fire safety standards, providing the highest standards in compliance and performance.

Third party tested by Warrington Fire, Profab Access’ VISION 8000 Series and INTEGRA 4000 Series Riser Doors are CERTIFIRE accredited up to two hours, whilst also being smoke sealed and Air tight to Part L. Both ranges also offer superior acoustic benefits, with the INTEGRA 4000 Series rated to 35dB and the VISION 8000 Series rated to 33dB.

This means in the event of a fire, the riser doors will maintain their frame and integrity for up to two hours, limiting the spread of fire and transmission of radiant heat for this period of time. The doors are also equipped with an intumescent smoke seal, which enables occupants to safely exit, whilst also minimising potential damage to the rest of the building.

Paul Wines, Project Manager at JJ Sweeney, said: “We have been specifying Profab Access’ extensive portfolio of access solutions for over 10 years, so we had complete confidence they would be the ideal manufacturer for such a high profile project.

“Installation of the riser doors and access panels took over eight months to complete, with myself and the JJ Sweeney team overseeing every aspect of the process. The end result is a high quality, aesthetically discreet finish that will offer the highest standards in performance for the entire life cycle of the building.”

Profab Access’ PRIMA 1000 Series Ceiling Access Panels were also installed throughout the building to provide secure access to overhead services. Featuring a unique pivot device for easy door removal and a push lock mechanism for enhanced usability, the access panels are constructed to offer contractors first class functionality, without impacting on the chosen interior design scheme.

Marcus Parnham, Commercial Director at Profab Access, said: “Our partnership with JJ Sweeney throughout this redevelopment project perfectly demonstrates the versatility and durability of our extensive range of riser doors and access panels.

“Sixty London Wall offers the very highest standards in contemporary office accommodation for the capital’s professionals, with our portfolio of access solutions facilitating the continuous maintenance of the building in an unobtrusive and effective way.”

Achieving an ‘Excellent’ BREEAM standard upon completion, the redevelopment of the building sets the standard for high quality sustainable office accommodation.

Achieving an ‘Excellent’ BREEAM standard upon completion, the redevelopment of the building sets the standard for high quality sustainable office accommodation.

For further information on Profab Access and its range of access panels, riser doors and steel doors, call +44(0)1827 719051 or visit https://www.profabaccess.com

View Access 360's profile:

Weatherite Cool With Condair ME

Story

The Condair ME evaporative humidifier is helping Weatherite reduce cooling system energy consumption for its data centre and telecoms clients by up to 80%. Condair’s evaporative humidifier is providing adiabatic cooling in Weatherite’s innovative Adtec-D free air cooling unit. The Condair ME boosts the cooling capacity of the system, allowing the Adtec-D to fully replace the need for mechanical cooling in some applications.

The Adtec-D is a self-contained, modular cooling system that can be located either inside or outside of a building. In data hall or telecom environments, for most of the year it operates in free air cooling mode and uses the outside air alone to cool the internal environment. However, when the outside temperature rises to around 20°C, the Adtec-D switches to adiabatic cooling mode. The incoming air is then passed through the Condair ME, which evaporates water into the fresh air stream, cooling it by up to a further 12°C.

By combining free air and evaporative cooling, Weatherite’s Adtec-D has recently been able to fully replace DX mechanical cooling across more than 800 switchgear rooms for a leading UK telecoms provider. A total of around 1,500 Adtec-D units have been deployed in the project to date. A single legacy 30kW DX and free air cooling unit was consuming around 71,000kWh annually to maintain the required internal temperature, operating 24/7. The replacement 30kW Adtec-D cooling unit consumes just 14,000kWh to meet the same annual cooling load. This resulted in an 80% energy saving for the client, which is a significant 83.3MWh annual saving in electricity across the UK-wide retrofit project.

Andy Lewis, Technical Manager at Weatherite commented, “The Adtec-D is an ideal retrofit solution for telco or DC clients who wish to take advantage of free air cooling rather than continuing to operate DX chillers. Available in modules that can provide from 15 to 80kW of sensible cooling, the Adtec-D will typically operate with an energy efficiency ratio greater than 15, even at peak outputs. The evaporative cooling technology, supplied by Condair, ensures the Adtec-D can maintain the allowable ASHRAE conditions, even during the warmer months in a European climate without the reliance on F-gas refrigerants.”

“Weatherite only uses the highest quality components in its HVAC solutions, and this includes Condair’s evaporative humidifier. It certainly delivered on our specific requirements for operation, control and hygiene management, and we’ve been very pleased with the support offered by Condair in connection with this successful project.” Andy concludes.

Dave Marshall-George, UK Sales Director at Condair, commented, “It’s a privilege to partner with Weatherite on such an innovative product that is helping the UK’s telecommunications sector meet its energy and sustainability objectives. As well as offering the most comprehensive range of humidifiers on the market, Condair has the ability to work with OEMs to create customised solutions. The evaporative humidifier incorporated into Weatherite’s Adtec-D is based on our standard Condair ME, but with some modifications to meet the project requirements. This project is an example of how Condair can develop innovative and flexible solutions for its customers.”

Weatherite is a leading UK manufacturer of made-to-measure HVAC equipment, based out of the West Midlands. Operating for over 50 years, the company provides a range of AHUs, heat recovery systems, packaged rooftop equipment and air cooled chillers.

The Condair Group is the world’s leading specialist in humidity control and evaporative cooling, with energy efficient, hygienic and innovative technologies for commercial, industrial and heritage applications. Condair is represented in the UK by Condair Ltd, which offers system design, manufacture, supply, installation, commissioning, maintenance and spares. You can find out more by visiting the company’s website at www.condair.co.uk.

View Condair's profile:

FUTURE Designs introduces carbon careful™ – a review of its commitment to the circular economy over the last 12 years

Story

FUTURE designs has pioneered the refurbishment and upgrading of existing luminaires and carcasses for over 12 years. Taking existing FUTURE Designs products and those of competitors, FUTURE Designs has renewed the luminaires with latest LED technology transforming them into highly efficient and carbon saving solutions, extending the lifespan and drastically reducing carbon usage and overall costs.

David Clements, FUTURE Designs Chief Executive explains: “The carbon careful™ initiative could be described as our “best kept secret”, as a hugely efficient design and manufacturing business we have always endeavoured to keep waste to a minimum, and now as the world is faced with a growing necessity to Refurbish, Reuse and Restore wherever feasible, we are sharing our story and expertise to encourage more organisations to follow suit.”

The carbon careful™ book showcases a range of examples from leading blue-chip organisations, highlighting FUTURE Designs proficiency, capability and commitment to the refurbishment of existing luminaire carcasses to increase the sustainability of commercial premises.

LED has been the lighting medium of choice for over ten years now but there are still millions of old fluorescent fittings being used to illuminate space. By switching to LED, energy and carbon usage can be reduced by circa 50%, coupled with the reuse of mild steel and aluminium, the savings are significant.

LED has a far greater lifespan, and its ‘solid state’ makes it easier to dispose of, without the risk of harmful gases such as mercury found in fluorescent lamps making it better for the environment.

FUTURE Designs is always at the forefront of any technological breakthrough, renowned for our expertise in this area of lighting science and have proven to be the experts in adapting old fluorescent lighting to state-of-the art lighting, ensuring that the benefits from the reduced impact on the environment are fully realised.

The full book can be viewed here: https://www.futuredesigns.co.uk/carbon-careful/