Category Archives: Manufacturing

Fahim Karim – new Specification Sales Manager for Saniflo

Story

Saniflo is pleased to announce the appointment of Fahim Karim as Specification Sales Manager for the South. This new role will focus predominantly on the Kinedo range of cubicles, enclosure and trays.

Having graduated from Brunel University in Uxbridge with Masters in Molecular Medicine and Cancer Research, Fahim was subsequently attracted to a career in sales and has since spent over 7 years in Specifications.

With experience in selling furniture, bespoke flooring and windows for new build and refurbishment projects he has excellent experience in dealing with architects, designers, developers, contractors and house builders; precisely the professional contacts required in this newly created role.

Outside work Fahim is an avid traveller and has explored the Middle East, Eastern Europe and America in the last few years. He is also a football and basketball fan.

View Kinedo's profile:

How to choose the right consumer unit and what to put in it

Story

Consumer units are often much more about what goes into them than what is already built in. This product information feature from Crabtree, one of Electrium’s leading brands in circuit protection, is a guide to choosing the right consumer unit and what to put in it.

When they say ‘the whole is greater than the sum of its parts’, they may not be talking about consumer units… but the analogy certainly fits!

A correctly selected and installed consumer unit plays a vital role in the safe use of electricity in the home. Its devices protect the installation and more importantly, the users, from faults and risks such as fire, and electrical shock.

Starbreaker consumer units have been designed to be easier, safer and faster to install, whether it’s a first-time installation, a re-fit or an upgrade, the range has been designed to be both backwards compatible as well as future-proofed.

Nothing demonstrates this better than the latest development in the circuit protection market.

New Regulations in the 18th Edition

With the release of the 18th Edition of the wiring regulations, which was published on 1st July 2018, a new type of circuit protection device was included under regulation 421.1.7 regarding AFDDs which stands for Arc Fault Detection Device. Starbreaker consumer units are the only consumer units that can accept AFDDs without the need for special busbars or assemblies, or on site adjustments.

Furthermore, because the busbar hasn’t changed since its launch AFDDs can be instantly fitted to any Starbreaker consumer unit, regardless of its age.

Starbreaker consumer units use an innovative instant self connection system by employing a unique busbar system that devices simply plug into for instant push fit connections that give guaranteed factory quality connections.

This makes the installation of devices easier, safer and faster. AFDDs can be simply plugged into the fully insulated plug in busbar system for an easy installation that meet 18th Edition standards for additional protection against electrically ignited fires.

30mA RCD Protection Extended

Today’s typical domestic installation will have 30mA RCD protection on every circuit, especially as another new regulation in the 18th Edition (regulation 411.3.4) has extended the use of 30mA RCDs to include all lighting circuits in dwellings.

All of which means that each circuit in a consumer unit needs to have several types of protection against a variety of potential faults.

By combining Crabtree AFDDs (Arc Fault Detection Devices) with the new Miniature RCBO (Residual current Circuit Breaker with Overcurrent protection) Crabtree have created a single device, capable of providing protection against all the fault conditions as necessary.

This device includes MCB technology, RCD technology and AFDD technology, providing protection against overcurrent, short circuit, earth leakage and arc fault conditions, all in one DIN mounted plug in 2 pole device that also switches the neutral for even higher levels of safety. They also help designers and installers comply with the 18th Edition IET Wiring Regulations.

It’s important that installers understand that AFDDs detect the types of arc faults that cannot be detected by RCDs or MCBs. These new devices use digital technology to provide additional protection against fires caused by arcs in AC 230V final circuits.

The 30% “Rule”

To help to avoid unwanted tripping of RCDs from PE currents (non fault leakage) the total PE current must be less than 30% of the RCD rating i.e. 30% of 30mA – see regulation 531.3.2.

Designers and installers will have to take account of PE currents when dividing the installation into the necessary number of circuits. Alternatively installers could simply use an individual RCBO on each circuit.

Only Use Manufacturer Approved Parts

Another new regulation, 536.4.203, refers to devices and components that are used in low voltage assemblies, such as consumer units, must only be those that have been declared suitable for that purpose by the manufacturer of the assembly.

Or put another way. Only use manufacturer approved parts, don’t mix brands of devices, or control items. Using unapproved parts will invalidate manufacturer guarantees and may result in an unsafe installation.

Meter Tails

The 18th Edition also includes regulation 522.8.5 which requires every cable to be installed in a way that avoids any mechanical strain and makes sure that there is no strain on the conductors and connections.

Consumer unit meter tails are included in this requirement. This is in addition to any other requirements to provide protection to tails at the point of entry into metal consumer unit enclosures etc.

Health and Safety

Regulation 462.1.201 requires a means of isolation (a main linked switch or circuit breaker) at the origin of every installation and in situations where this will be operated by ordinary persons, e.g. on a consumer unit in a domestic household, the main switch must interrupt both live conductors (L and N) of a single phase supply.

Starbreaker Mini RCBOs and AFDDs provide this same safety protocol to individual circuits too because they include switched neutral as standard.

Periodic Inspections

The 18th Edition recommends periodic testing and inspection (regulation 135.1).

Testing can be a time consuming and costly activity, but Starbreaker Miniature RCBOs allow IR testing to be carried out without disconnecting and reconnecting circuit cables because they include two pole isolation as standard. Just switch off and test. Easier, safer, faster.

So, whether it’s a brand new installation, an addition or upgrade, Crabtrees’ Starbreaker consumer units and devices (Miniature RCBOs and AFDDs) can be simply plugged into the fully insulated plug self-connecting busbar system.

Providing an easy installation that now includes additional protection against electrically ignited fires.

Get more on the 18th Edition

Be clued up on the 18th Edition and the changes that are coming through by visiting our 18th Edition Area.

We’ll be talking more about AFDDs, Surge Protection, RCD and more.

For more information go to www.electrium.co.uk/18th-edition

View Crabtree's profile:

Introducing the MagnaClean DRX

Story

The brand new MagnaClean DRX is now available.

Its innovative and compact design includes a magnetic belt wrapped around a precision engineered stainless steel case which makes installation and servicing quick and easy.

The MagnaClean DRX has a robust and versatile design

The DRX has joined ADEY’s family of filters which are designed specifically for commercial systems. It will provide essential protection for plant rooms and comes complete with a host of features to provide a versatile solution for heating engineers:

Innovative and compact design which includes magnetic belt technology

• Flexible installation options – for both in-line and side stream applications

• Easy to service

• Effective capture of black iron oxide sludge

• Captures large and small size particles

• Available in sizes 2”, 2 ½”, 3 “ and 4”

To see the DRX’s design for yourself, you can watch a brand new video that is available via the ADEY YouTube channel: https://youtu.be/mOVnVCFNpAs

Along with the rest of ADEY’s range of Commercial filters, you can also download Building Information Modelling (BIM) technical data for the Magnaclean DRX by visiting adey.com / bim-store or via bimstore.co.uk

ADEY’s Commercial Division has also been expanded to support their customers further:

The continued expansion of ADEY’s Commercial Division now means that customers have access to a dedicated and highly-experienced team who are able to offer focused technical insight, help and advice, no matter what the system size, scale or problem.

To request a free site visit where a member of the ADEY team will come out and assess your plant room, just go to www.adey.com/support/customer-support

You can contact ADEY on 01242 546 717 or via info@adey.com

You can also keep up to date with ADEY’s latest activities via their social media channels: Facebook, Twitter, YouTube, Instagram and LinkedIn. And if you would like to find out more about the MagnaClean DRX or ADEY’s Commercial range, please visit adey.com

View Adey's profile:

Crabtree: How Arc Fault Detection Devices can benefit your next installation

Story

Arc Fault Detection Devices are a new addition to the 18th Edition of the Wiring Regulations. This product information feature from Crabtree discusses why arcing shouldn’t become an after thought.

The Wiring Regulations define danger as: “Risk of injury to persons from: fire, electric shock, burns, arcing and explosion arising from the use of electrical energy.” Not that this should surprise us, electricity is a dangerous commodity.

In England in 2016/17, there were 13,347 fires from an electrical origin. Electrical fires are continuing to occur at virtually the same rate year on year, even though many of these incidents are preventable.

Perhaps this is partly because buildings have more items of electrical equipment in them than ever before? Electrical fires caused by arc faults typically occur at loose connections, poor terminations, in damaged leads and cables, or through old, weak and failing insulation.

Arc Fault Detection Devices (AFDDs), can decrease the likelihood of electrical fires from these conditions by detecting the arcing conditions before the overheating and ignition of flammable materials. In countries like the USA, where use of AFDDs started some years ago, there’s been a reported reduction of 10% for this type of incident.

Dave Enefer, Product Manager at Crabtree, comments: “The wiring regulations (BS7671) sets out requirements for electrical installations in the UK, including requirements for protection of persons, livestock and property against the risk from fires that may be generated and propagated in electrical installations.

“Designers and installers should ensure that the installation is arranged so that the risk of ignition from high temperatures or electric arc is minimised, and that protection from harmful thermal effects is provided. Protection requirements include protecting against fire caused by insulation faults, arcs and sparks and high temperature.”

Clearly the wiring regulations require certain design and installation standards. It is permitted to use RCDs as a measure for protection against insulation faults, it’s also a requirement to install other circuit protection devices such as MCBs to provide protection from overcurrent and other conditions.

However, those devices cannot detect or disconnect arc faults. AFDDs detect arc faults that will not be detected by RCDs or MCBs due to the fact that the magnitude of such arc faults is often insufficient to operate an RCD or MCB.

Crabtree Arc Fault Detection Devices cater for the all of the above requirements because the AFDD technology is combined with MCB and RCD technology in one single device, providing for all of the requirements of BS7671.

In countries that have already adopted this technology AFDDs are often used in buildings with sleeping accommodation, those made from combustible materials, and locations with rare or irreplaceable items. Imagine how many incidents could be prevented if these devices were installed in all such locations?

What’s an AFDD?

AFDDs work by protecting specifically against arc faults, as they automatically trip a circuit when they detect dangerous electric arcs – thus preventing the outbreak of a fire.

An arc fault occurs when the arc current either flows between active conductors in parallel with the load of the circuit or when it is flowing through the load(s).

Arcing is incredibly dangerous because it creates high intensity heating at the point of the arc, resulting in burning particles that may, over time, ignite surrounding materials. Moreover, repeated arcing creates carbon paths which generate temperatures exceeding 6,000 degC.

It can take time to develop, it can occur immediately or over a longer period, meaning that the onset of an electrical fire due to ignition of the cable insulation or nearby flammable materials is unpredictable.

AFDDs constantly monitor and analyse patterns in voltage waveforms and electrical current, looking out for divergence from normal patterns of waveform that denote a potentially dangerous arc.

They are designed and tested to not respond to arcing under normal operation of equipment, for examples vacuum cleaners and drills, whilst simultaneously continuing to respond to arc faults whilst the equipment is being used.

Electrical fires can be decreased in number by the use of this recognised device that installers can now easily access and install.

You can read more about Crabtree’s AFDD solution via www.electrium.co.uk/products/crabtree

And there is more about Arc Fault Detection Devices and the 18th Edition over at the 18th Edition Area of the Electrium website at www.electrium.co.uk/18th-edition

View Crabtree's profile:

New weatherproof waterbar addresses key challenge for ICF installers

Story

Triton has introduced Cemflex VB Steel Waterbar, a fully weatherproof BBA certified waterbar that doesn’t need to be protected from rain prior to the concrete pour. It addresses a key challenge in below ground basement construction for installers of quality ICF systems and pre-cast concrete twin wall systems, who need to form a good watertight seal between the ICF blocks or the twin wall panels and the basement slab.

Traditional hydrophilic waterstops have been around for many years and can be used successfully in most applications. However when the blocks forming the structure are not in-filled with concrete for some time, and the waterstop is exposed to rain within the open blocks, this will cause it to start swelling prematurely and result in subsequent underperformance in a very critical location. Attempting to remedy this by the removal of the waterstop is usually impossible due to its location inside the ICF blocks or twin wall panels.

BBA certified Cemflex VB Steel Waterbar is a galvanised steel plate encapsulated in a special patented coating that reacts only with the water within the concrete to provide a watertight joint. It’s designed for use in all non-movement construction joints in reinforced concrete – and is especially suited to ICF or twin wall installations.

Quick and easy to install with no sticky tape to remove prior to use, it can be installed before the concrete is poured by positioning to steelwork, or directly into the fresh concrete after pouring. Cemflex VB Steel Waterbar is 1.25mm thick and supplied in two metre lengths in a choice of 100mm or 150mm widths. Find out more at tritonsystems.co.uk or speak to your local Triton technical manager.

View Triton Systems's profile:

Podcast Now Available: BNE Product News – BBA – ‘Special Edition’ Interview

Story

Podcast Now Available: BNE Product News – BBA – ‘Special Edition’ Interview

In this BNE Product News ‘Brand Leader’ podcast, Alvaro Enguita-Gonzalez – Head of Test at the BBA discusses the BBA Product Excellence Programme (PEP). The interviewer for BusinessNet Explorer is Mick de Leiburne.

Click to play interview on YouTube:

View BBA's profile:

Saniflo launches new website

Story

Saniflo UK – the country’s leading designer and manufacturer of macerators, pumps and shower cubicles – has launched a new website available at saniflo.co.uk, offering access to a a raft of information for homeowners wishing to find out more and upgrade their homes using a Saniflo product. Live from mid-October, the new website makes it easy for homeowners to search and find the products they need.

Selecting the right product can be achieved in a number of ways. The ‘Our Products’ tab enables a search via conversion type or product group. ‘Your Project’ takes the user through a selector tool that highlights the Saniflo products relevant to the job the customer wishes to carry out.

A range of installation videos are available on the home page. Aimed at highlighting the ease of installation of Saniflo products these videos are useful for plumbers, installers and DIY’er’s alike. Brochures can be downloaded from the customer service section and customers can also register purchase details here too to ensure they benefit from the generous 5-year warranty protection on the domestic product range.

The Pro site has an added link to the installation instructions for the full range of Saniflo products and has been designed for the addition of future content. In due course more product and instructional videos will be added along with educational assets.

Of course the Saniflo technical team is just a phone call away if any further information is required.

The best way to find out more about the new site is to try it at www.saniflo.co.uk

View Saniflo's profile:

New Dehumidifier Sales Manager at Condair

Story

Condair has appointed Julien Taschot as Business Development Manager for its range of industrial and commercial dehumidifiers. Julien’s role will be to develop sales of Condair’s dehumidification systems across the UK and Ireland.

Julien has 11 years’ experience in humidity control having been with Condair in various sales positions across both the UK and French Condair offices. His previous role within Condair was to support international sales of adiabatic humidification systems manufactured in the UK but sold internationally throughout the Condair Group.

Julien comments, “I am delighted to be joining Condair’s UK Sales team and to be playing a central part in Condair’s focus on dehumidification systems. Condair is largely known for adding moisture to the atmosphere with its range of humidifiers so this newly created role within the company highlights Condair’s commitment to this sector.”

Condair’s range of dehumidifiers incorporates both desiccant and condensing technologies and is suitable for any commercial or industrial drying application. Standard capacities range from 0.5-182kg/h extraction rates, -30°C to 40°C operating conditions and dry air volumes from 120 to 25,000 m³/h.

The Condair Group is the world’s leading specialist in humidity control and evaporative cooling, with energy efficient, hygienic and innovative technologies for commercial, industrial and heritage applications. Condair is represented in the UK by Condair plc, which offers system design, manufacture, supply, installation, commissioning, maintenance and spares. You can find out more by visiting the company’s website at www.condair.co.uk.

View Condair's profile:

The show that’s got decorating covered

Story

On November 27 and 28, the decorating trade will convene at Coventry’s Ricoh Arena for the 2018 National Painting and Decorating Show.

For professional decorators, contractors, merchants and stockists, this is the annual trade event that has the entire decorating sector covered. Paint and wallpaper, preparation tools and applicators, colour trends and time-saving techniques – show visitors will see the latest in product innovation as well as plenty of trusted best sellers.

From Dulux, PlastiKote, tesa and Wagner to Brewers, Crown, 3M, Graco and Benjamin Moore, the 2018 show will again feature hundreds of products, brands and suppliers revealing the latest trends and textures making news across the decorating market.

Every year this show buzzes with product launches, hands-on demos, theatre sessions, show-only deals, free samples, how-to information, competitions, raffles, prize draws, sporting challenges and celebrity guests.

Several special features also help visitors make the most of their time at the show. Making its debut at the 2018 event is SprayZone, designed to take the mystery out of spraying. Visitors will have a hands-on opportunity to hone their paint spraying skills, instructed by experts in the proper and safe use of several different types of equipment.

In the two MasterClass theatres, sponsored by Packexe, again this year industry experts will present practical information and demonstrations, and reveal tricks and techniques of the trade every 30 minutes throughout the two-day show.

The popular Lucky Dip will be back again, making everyone a winner of useful gifts, product samples and promotional items.

The CoffeeZone, sponsored by Crown Decorating Centres, will provide visitors with a welcome break as they shop the show. And each day the first 1000 pre-registered visitors to arrive at the event will receive a complimentary product-packed DecoBag.

The show venue, complete with on-site hotel, parking, restaurants and bars, is easily accessible by road, rail and air. It’s just a two-hour drive from 75% of the country, Birmingham Airport is a short drive away, and an on-site train station provides an hourly service between Coventry City station and Ricoh Arena.

The National Painting and Decorating Show provides visitors with a valuable networking opportunity to meet exhibitors face-to-face, find out who’s doing what in the decorating industry, and exchange ideas and solutions with like-minded decorating professionals.

For FREE tickets, visit www.paintshow.co.uk

View National Painting & Decorating Show's profile:

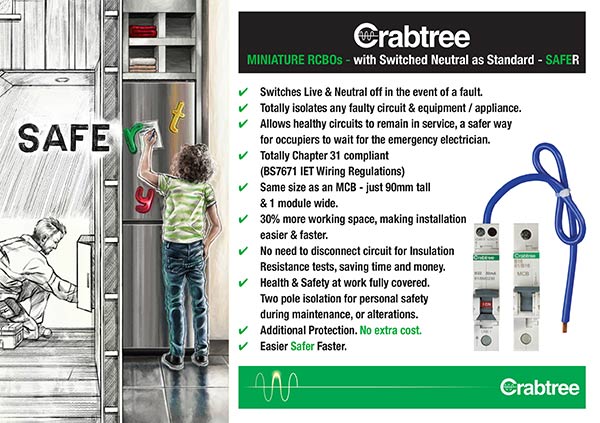

RCBO Spells Savings for Testing

Story

Can one component really make testing easier, safer and faster? Dave Enefer, Devices Product Manager at Crabtree, one of Electrium’s leading brands in electrical components, talks about achieving time and cost savings in periodic circuit testing.

Testing is an essential activity, yet it can often be a time consuming one, whether it has to be repeated annually or more or less frequently at regular intervals.

Obviously, this means that there’s a cost to be budgeted for, with time and labour being the most expensive part. So, if there’s a product on the market that can make testing easier, safer and faster why wouldn’t you use or recommend it?

Responsible social landlords, for example, will have a programme of periodic testing of the electrical installations in the dwellings that they own and rent out. T

hey do this not only because it’s recommended in the IET wiring regulations, regulation 135.1 and Chapter 65, but also to ensure that their tenants have a safe environment in which to live.

In social housing situations periodic testing is often carried out more frequently than other types of installation because every time there is a change of tenant, the housing authority or association will check the electrical installation before the next tenant moves in.

Ordinarily when this involves insulation resistance (IR) testing on circuits that are protected by RCBOs, the circuit cables on the RCBO circuits need to be disconnected.

This is so that the IR tester does not damage the electronic components inside the RCBO, but that slows down the testing process, adds cost and introduces risk.

It takes time to disconnect the live and neutral cables, and attach the test leads to each core in turn in order to carry out the test.

It then takes more time to put those cables back into the terminations on the RCBO and make a secure connection again so that the installation can be put back into use.

However, making that secure connection might mean stripping the cable insulation back a little further to find fresh undamaged conductor cores to put into the terminals (It’s a fact that copper cables can’t be repeatedly disconnected and reconnected without getting damaged from the screw biting into the cable core).

However, all of that can be avoided with Crabtree Miniature RCBOs, as they are two-pole switching devices.

The only thing that has to be done to get a circuit ready for an insulation resistance test is to switch the device off. This saves time and money from your annual budget on essential testing, and provides higher levels of protection for all who interact with it.

In a single second the circuit is ready to test. There’s no need to disconnect the circuit cables, no need to attach test leads, and no need to be concerned about reconnecting cables either. All of which makes this testing process easier, faster, safer and cheaper too.

By taking some of the cost burden away from the regular testing of circuits, it not only makes it more competitive for contractors quoting for ongoing periodic testing but it also then enables the property management company or social landlord to invest more of their increasingly tight budgets into the upgrade of old systems and the implementation of new ones.

Crabtree Miniature RCBOs are just one module wide and the same height as an MCB, so they provide lots of extra wiring space during the installation and test process. Regular maintenance is made safer by the two pole switching capability of the device.

The device also totally isolates any faulty circuit or faulty appliance and provides a much safer environment while waiting for the emergency electrician.

When they arrive, having the faulty circuit fully isolated by a two pole device provides a safe working environment for the task of maintenance or and repair as necessary.

By the way, it’s not just new installations that can benefit from these new and innovative miniature RCBOs.

Crabtree Miniature RCBOs are designed to fit into all Crabtree Starbreaker consumer units, whatever the age of that consumer unit might be.

Crabtree Miniature RCBOs are fully retrofit / backward compatible and can be simply plugged into the fully insulated plug self-connecting busbar system for an easy upgrade from single pole to two pole protection – making the ongoing time and cost benefits from testing readily accessible.