Category Archives: Manufacturing

Triton shares Structural waterproofing expertise

Story

Waterproofing of Structures Below Ground is the latest CPD accredited by the RIBA for structural waterproofing specialists, Triton Systems. It offers a complete overview of all aspects of structural, below ground waterproofing and explains barrier, watertight concrete and cavity drained systems (defined in BS 8102:2009 as Types A, B and C). It looks at systems available, as well as the benefits of combining two or more types. It presents examples of typical details and good site practice, and showcases a variety of project references. Triton Systems uniquely have in-house expertise across all waterproofing systems for new-build including large commercial projects and existing structures.

The new seminar is just part of a series of waterproofing-related,RIBA accredited seminars from Triton Systems which are all listed at tritonsystems.co.uk

The company also offers a wider range of Professional Learning CPDs – which can be tailored to specific audiences including architects, building engineers, concrete project contractors or specialist installers.

An alternative learning opportunity is also available from Triton in the form of a ProjectReview Meeting. Arranged at a time and place to suit you, a CSSW qualified member of Triton’s technical team will drop in and provide unbiased project-specific advice for a current or imminent waterproofing project – just when you need it – and follow it up with detail drawings and specifications etc.

BS 8102 (2009) recommends the involvement of a qualified expert at the outset of any waterproofing project – the Triton team is ready to get involved with your projects!

View Triton Systems's profile:

PTS Launch New Responsive Website

Story

Precision Technology Supplies Ltd, one of Europe’s favourite suppliers of Stainless Steel Metric and Unified Fasteners, are pleased to announce the arrival of our new exciting website. The new site is responsive and designed to work on mobile devices as well as desktop pc’s.

Incorporating the latest in search technology giving you the easiest route to finding exactly what you require. With over 45,000 products available this facility helps speed you through the product catalogue. Full dimensional data along with 2d and 3d drawings are available for all items to assist you.

The customer area allows customers to login and to place and track orders, view order history and download copy invoices and statements. The webstore also offers the ability to enquire on products not in stock or not shown as available, including special and non-standard items.

Multi-currency and multi lingual options are available along with worldwide shipping options. Worldwide shipping is via UPS offering express options as well as access point shipping. Making this the one stop shop option for all your Stainless Steel fastener needs.

For one of the widest ranges of Quality Stainless Steel Fasteners available please visit us at www.pts-uk.com.

View Precision Technology Supplies's profile:

Ancon honoured at third Buckingham Palace Royal Reception

Story

Ancon has been honoured at a Royal reception to celebrate its success in the 2018 Queen’s Awards for Enterprise – the third Queen’s Award for the company.

The champagne reception, held in the State Rooms of Buckingham Palace, was hosted by HRH The Prince of Wales, on behalf of HM The Queen. Other members of the Royal Family, including HRH The Duke of Kent, were in attendance, underlining the status of this prestigious industry award.

Ancon’s Export Manager, Hervé Poveda, and Operations Director, Peter McDermott, represented Ancon at the event, along with representatives of its business partner, MagmaTech, joint winners with Ancon of the 2018 award.

It was a very proud moment for the two Ancon representatives who share over 50 years’ service and have played important strategic roles in the company achieving and maintaining UK market leadership and its significant international growth.

Speaking after the reception, Hervé Poveda said ”What a wonderful personal experience to meet the Royal family at Buckingham Palace and a great honour to be asked to represent Ancon at this event. A Queen’s Award not only recognises expertise in developing new products or achieving commercial success, but also excellence in every area of business. I am proud to be a part of an organisation that has proved itself, once again, to be among the best in the world.”

Peter McDermott added, “Winning one Queen’s Award is a great achievement, but winning three is a real measure of the depth of expertise, knowledge and dedication that exists within Ancon, at every level of the company. Today is a proud moment for every Ancon employee as well as our suppliers, customers and partners who have contributed to Ancon’s achievements throughout the world.”

Ancon’s latest Queen’s Award, for continuous excellence in innovation, comes as a result of expanding into advanced composites, with the successful introduction and on-going development of the ultra-low thermal conductivity Teplo range of basalt fibre wall ties, which improve the energy efficiency of masonry construction.

This success follows Queen’s Awards for International Trade in 2015, for three years of outstanding sales growth across new and existing export markets, and a Queen’s Award for Innovation in 2012, for the in-house development and commercialisation of a patented Lockable Dowel, a product that revolutionised the construction speed of post-tensioned concrete buildings.

The 2018 Award will be officially presented to Ancon later in the year when the Lord Lieutenant of South Yorkshire, HM The Queen’s local representative, visits the company’s recently-extended production facility in Sheffield.

View Ancon's profile:

Crittall windows feature in latest RIBA awards

Story

A showpiece re-use of a former London retail store in which new Crittall windows and doors are a key feature has won two major architectural awards.

The Department Store in Brixton now serves as the magnificent headquarters of architects Squire & Partners. It has been named as a winner in both the Royal Institute of British Architects’ 2018 National and London Awards.

A dilapidated shell was all that remained of the once stylish 1906 store. Multi-award-winning architects Squire & Partners decided, in moving their head offices from Kings Cross, to strip the sad Brixton building back to its raw original condition and, in so doing, reveal the decaying grandeur of its original construction and fittings. These features would be re-used where practicable and highlighted.

These included original first floor Crittall windows, featuring distinctive circular glazing bars, while new internal screens, roof terrace fenestration and ground floor storefront windows, some including curved glass, were installed, using Crittall MW40 and W20 profiles.

RIBA award judges said this was: “A stunning building which has been brought back to life”. It had undergone “Exceedingly exquisite and sensitive restoration, filled with beautiful material choice, attention to details and wonderful spaces.”

Particularly noted was the architectural modelling space on the ground floor “providing inspiration to passers-by who peer inside to see the display of what architects do and how we work.” It is the new Crittall storefront windows that afford this view.

The re-born Department Store now offers more than 6,000 square metres of space spread over four floors incorporating open plan offices, breakout areas, meeting rooms, exhibition spaces, a model-making workshop, a café, bar, roof terrace and a record shop. Clumsy later additions and extensions were removed in the restoration and its original wooden floors, brickwork, marble, terracotta and, of course, steel windows, have all contributed to a truly back-to-the-future design.

The RIBA judges concluded: “This project has a sense of fun mixed with honouring history which brings delights to those who step inside.”

For Crittall Windows group chairman John Pyatt said: “We were delighted to have been part of this tremendous building transformation which underlines the fact that our products never go out of fashion.”

View Crittall's profile:

Saniflo celebrates 60 years of innovation

Story

The Saniflo macerator is celebrating its diamond anniversary and to celebrate the company is launching a unique prize draw which can be entered by installers each time they purchase one of a range of domestic macerators between 15th May and 31st September 2018.

The Saniflo macerator is celebrating its diamond anniversary and to celebrate the company is launching a unique prize draw which can be entered by installers each time they purchase one of a range of domestic macerators between 15th May and 31st September 2018.

It’s hard to believe that the first Saniflo was launched some six decades ago in France. The very first units were invented to provide extra wc facilities in apartment blocks in France. In the sixty years that have followed the innovation has continued and today Saniflo has the most comprehensive line-up of macerators, pumps and lifting stations for commercial and domestic markets and is not only the UK market leader, but has become the generic term for macerators in the same way as hoover has for vacuum cleaners.

To recognise the landmark in the company history there will be special stickers on the boxes of the Saniflo Up, Sanipro Up, Saniplus Up, Sanivite+, Sanishower+ and the Sanispeed+ between those dates and these will explain how to enter the draw to try and win cash prizes including: 1 prize of 6000 Euros, 10 prizes of 600 Euros and 100 prizes of 60 Euros. The Sterling equivalent will be available.

A website URL and QR code printed on the sticker takes the installer to a dedicated web page where he/she can enter the relevant details and submit a proof of receipt whereupon he or she will be automatically entered into the random draw which will be drawn in October 2018. It is possible to enter the draw more than once; every purchase of a relevant product entitles the purchaser to a further entry.

For a copy of the full terms and conditions please visit www.saniflo.co.uk

View Saniflo's profile:

3D printing used to create new multi-waste manifold for high-rise applications

Story

With the increase in demand for high-rise accommodation across the UK, soil and drainage specialist Saint-Gobain PAM has utilised the latest in 3D design and printing, to create a new low connection multi-waste cast iron manifold, aimed at tackling the drainage challenges faced by contractors building high-rise structures.

With the increase in demand for high-rise accommodation across the UK, soil and drainage specialist Saint-Gobain PAM has utilised the latest in 3D design and printing, to create a new low connection multi-waste cast iron manifold, aimed at tackling the drainage challenges faced by contractors building high-rise structures.

The new manifold addresses the trend towards walk in showers and wet rooms, whilst also recognising the squeeze on distances between floors and smaller ceiling voids in which to fit services and make the necessary waste water connections.

Commenting on the development of its new manifold and its adoption of 3D printing for rapid product development, Mike Rawlings, Marketing Manager for Saint-Gobain PAM said:

“Our collaborative 3D design and print approach allows us to quickly address industry challenges across different sectors. We now have the ability to develop and test prototypes in a matter of days. This is achieved by producing a resin model and then using it to develop a mould for a cast iron component, so customers can physically see the solution.

By being able to collaborate with the industry in this way, we are able to dramatically cut down the development to production cycle, enabling customers to quickly benefit from new products like the low connection multi-waste manifold.”

The new low connection multi-waste manifold is available initially in 100mm diameter but will be closely followed by 150mm diameters by the end of March. The fittings offer up to six 50mm/2” BSP waste inlets and have been flow rate tested by CRM Rainwater Drainage Consultancy. The 100mm unit has been tested to a vertical flow of 1.8 l/s which is consistent with a 6 l/s WC flush and all six 2” waste inlets at a flow of 1 l/s at the same time. The manifold has an internal baffle to eliminate any cross flow.

Designed for easy installation, the 2” waste inlets comfortably fit in the ceiling/floor area and an extended spigot accommodates a floor slab of up to 400mm without the need to make connections. The spigot has 10mm cut marks to make it simple to cut to length. Both the 100mm and 150mm diameter manifolds minimise the core hole diameter, fitting into a 200mm or 225mm hole respectively.

The new cast iron low waste connection manifold is available in both the Ensign range with mechanical joints and the fast installation EEZI-FIT range with its push fit connections to product standard BS EN 877.

For further information about the low waste connection manifold, contact: Saint-Gobain PAM UK, Lows Lane, Stanton-by-Dale, Ilkeston, Derbyshire. DE7 4QU. Tel: 0115 930 5000. Email: Sales.uk.pam@saint-gobain.com Or visit: www.saint-gobain-pam.co.uk

View PAM Building's profile:

Bona introduces wood floor styling at Clerkenwell

Story

As a showroom partner, wood floor specialist, Bona, through twice daily talks, will introduce the Clerkenwell community to its new ‘Inspiration’ wood floor styles, designed to transform the look of tired, existing wood floors or to embellish unfinished new ones.

As a showroom partner, wood floor specialist, Bona, through twice daily talks, will introduce the Clerkenwell community to its new ‘Inspiration’ wood floor styles, designed to transform the look of tired, existing wood floors or to embellish unfinished new ones.

Created by Bona in collaboration with internationally recognised trend analyst, Cay Bond, each of the 17 new looks can be achieved using a combination of Bona’s sanding and brushing methods to enhance the grain, followed by treatments with the company’s waterborne lacquers, oils and colours. The styles, Nordic Shimmer, Garden Atmosphere, Malibu Dreams, Touch of Grace and New Modern, include everything from dark, rustic floors to floors with a pale, lacquered finish.

Floor owners are often simply not aware of how an existing wood floor can be transformed, giving a room or space a completely new look and feel. From a sustainability perspective it makes sense too – the old floor has already been manufactured and transported.

A campaign starts on June 1st using social media, print and online advertising to target and inspire floor owners. Contractors will be able to use the professional pages at bona.com to see how the individual looks can be achieved, and samples and beautiful inspirational brochures will also be available for designers, architects and flooring contractors to leave with their clients.

Register for twice daily showroom talks entitled ‘Inspiration through renovation – how to achieve contemporary trends on existing wood floors’ at this link – https://www.bona.com/en-GB/Professional/Support/Events/Clerkenwell-Design-Week/ or via Bona’s Showroom page at clerkenwelldesignweek.com

View Bona's profile:

Expansion into advanced composites brings third Queen’s Award for Ancon

Story

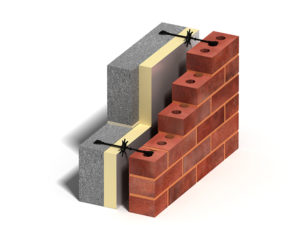

Structural fixings manufacturer, Ancon, has won a 2018 Queen’s Award for Enterprise in the Innovation category, for the successful introduction and on-going development of its advanced composite, low thermal conductivity, Teplo wall tie range.

This is the third time that Ancon has been honoured in this prestigious award scheme that rewards outstanding achievements by UK businesses; it follows Queen’s Awards for International Trade in 2015 and Innovation in 2012.

Teplo wall ties are manufactured from continuous basalt fibres set in a resin matrix; a fibre-reinforced polymer that is 70 times more thermally efficient than steel. When used to join the two leaves of a cavity wall, this material virtually eliminates cold bridging across the insulated cavity. Launched by Ancon in 2010 as part its market leading wall tie range, Teplo has had a major influence on the growth of low energy housing in the UK and Ireland, and helped future-proof traditional masonry cavity wall construction techniques, by minimising insulation thickness and wall footprint.

Whilst Ancon’s first Queen’s Award for Innovation in 2012 recognised the company’s in-house development of a unique lockable concrete-connecting steel component, this second Innovation award has been won jointly with its external strategic partner in this advanced composite development, MagmaTech.

Head of Marketing and Innovation at Ancon, Annabelle Wilson, says “Ancon launches a number of new and improved structural fixing solutions every year and invites ideas into our innovation process from both inside and outside the company. We saw potential in this new material immediately, and over the last eight years have committed our business resources to improving and extending the Teplo wall tie range as part of the Ancon product portfolio, bringing the benefits of advanced composites to mainstream UK construction.”

Today, the Teplo wall tie range includes Teplo-L suitable for surface-fixing in timber frame construction, the Teplo-BF with moulded safety ends that improve buildability particularly in lime and other slow-setting mortars, and the Teplo-BFR which can be resin-bonded in existing walls for retrofit applications. Teplo has been used in numerous ground-breaking developments, including the UK’s first masonry cavity wall ‘PassivHaus’, the UK’s first zero-carbon retrofit and the largest building in the UK built to the ‘Passivhaus’ standard, the University of Leicester’s Centre of Medicine.

Ben Williams, MagmaTech’s Managing Director says “Ancon has proven to be an exceptional partner for cutting edge innovation. They embraced a concept that was potentially disruptive to their existing stainless steel business, promoting it with passion and commitment. Taking a truly innovative energy-saving product to this level of market acceptance in just a few years is a truly outstanding achievement, surpassing our expectations.”

Commenting on their latest triumph in the Queen’s Award programme, Ancon’s Managing Director, Stuart Maxwell, says “Winning three Queen’s Awards in seven years is an extraordinary achievement and reflects the level of professionalism with which Ancon employees, in all areas of our organisation, go about their daily business. Our focus on quality and innovation, combined with a single-minded determination to excel in everything we do, not only underpins our brand reputation in the UK but its growing significance worldwide. It is another very proud day for everyone connected with Ancon and I thank our employees – both home and abroad – our customers and our suppliers for their continued support.”

Later this year the Lord Lieutenant of South Yorkshire will visit Ancon’s head office and main manufacturing site in Sheffield and officially present the 2018 award on behalf of HM The Queen. Ancon representatives will also attend a royal reception at Buckingham Palace this summer, hosted by HRH the Prince of Wales and other senior members of the Royal household.

Later this year the Lord Lieutenant of South Yorkshire will visit Ancon’s head office and main manufacturing site in Sheffield and officially present the 2018 award on behalf of HM The Queen. Ancon representatives will also attend a royal reception at Buckingham Palace this summer, hosted by HRH the Prince of Wales and other senior members of the Royal household.

View Ancon's profile:

How REHAU Recycles

Story

Ever wondered how old PVC-U window frames are transformed into brand new ones? Well wonder no more as Richard Hardstaff, General Manager at PVCR, explains it all:

Q: How easy is it to recycle PVC?

A: PVC is very straightforward to recycle and can be mixed with virgin polymer to give it a whole new lease of life. PVC can be recycled up to 10 times.

Q: Can any recycled plastic be used to make new window frames?

A: The types of material we deal with at PVCR are best recycled into new versions of themselves – so old PVC windows are transformed into new ones, old water bottles are made into new water bottles etc.

Q: Which PVC window frames can be recycled?

A: Ideally we want good quality de-glazed window and door frames to ensure the recycled material is of a good standard. Laminated frames are also OK to recycle.

Q: What processes are involved in recycling PVC?

A: Firstly, the frames are broken down and put into a shredder to reduce the size of the material, and any metal is removed. Next, the material is put in water and essentially everything we want sinks. We then separate the material again using a vacuum to ensure any rubber or leftover metal is removed before it goes into the granulator.

The granulator reduces the material to 10mm in size, before its washed, dried and put through electrostatic separation to remove any remaining residue or organic material. Its then colour sorted before the clean, white PVC material is ready to send to REHAU’s factory in Wales.

Q: What is the PVC material used for in the manufacturing process?

A: After being cleaned and lab tested, the white PVC material is sent to REHAU’s factory in Blaenau, where it used to make TOTAL70 co-extruded profiles.

Q: Is there growing demand for recycled PVC?

A: We have seen a dramatic increase in demand and by 2019 our capacity will have doubled, if not tripled.

Q: What’s the reason behind this uplift in demand?

A: Consumer demand is the main driver. By using recycled plastic, businesses can meet the needs of eco-conscious customers, give their products a USP, and do their bit for the environment.

For more information and to see the process in action visit www.pvcr.co.uk

View Rehau's profile:

Large span windows and doors set new design standard

Story

Much has changed in relation to door and window technology over the past 20 years and this is reflected in the increasing popularity of features such as large span roof windows and bi-folding doors. Both are now used as an intrinsic element of interior design as they enable natural daylight to transform areas in which we live and work.

For walls, use of floor to ceiling glazing has enabled exteriors to be ‘brought into’ the living environment, capitalising on views provided and enhancing perceptions of space. Design engineers are now, however, able to maximise the functionality of timber and aluminium to produce far larger sash and frame profiles than ever before. This requires a level of precision beyond the capability of traditional manufacturing techniques while, in terms of design complexity, durability, security and thermal / acoustic performance all have been considerably improved.

The type of timber used for the weight of such windows and doors is critical so Fakro opted for pine, oak and meranti hard woods to provide a combination of high performance and a high visual aesthetic. They also provide long-term structural stability, a critical factor not just for the ability to withstand distortion but to retain energy efficiency and airtightness. This was the driving factor influencing design of the Innoview range, in which triple and quadruple-glazed construction is used with low emissivity glazing and a quadruple sealing system. With warm spacers between panes, the overall heat transfer coefficients in is as low as 0.68/W/m2K (with Ug values of 0.3W/m2K in quadruple-glazed units).

Designs in which windows of such a large span are specified inevitably necessitates manufacture of bespoke sizes for individual projects. In achieving the ability to do so, Fakro can now fulfil the same service it has been providing with roof windows for more than 20 years. This enables architects and interior designers to create homes and work places with a distinctive identity and character while also meeting specific technical aspects of performance.

With scope to specify colours from the RAL Classic Palette and use of close-grain timber from FSC-certified sources, the standard of internal finish immediately provides clear evocation of quality. Modern coating and lacquering techniques, matt or satin finishes and choice of sash profile enable the windows and doors to complement the most diverse interior design requirements. Appearance is enhanced by concealed hinges and invisible fixings while use of sliders in conjunction with a roller lifter and rotary cam ensure that positioning in the frame remains constant, regardless of usage intensity. Soft closure also slows the sash movement prior to positioning it in the frame. Such ease of operation has been described as ‘out of all proportion to what might be expected from windows of such a size’.

EPDM rather than silicone seals are used as they provide far greater long-term reliability through their shrinkage resistance and bond between glazing and frame. This not only gives far greater assurance of air and weathertightness but provides a greatly improved standard of finishing. Windows and doors have anti-burglary, multi-point locks and Class RC1 or RC2 glazing units (the latter optional extra providing nine locking points per window). The hardware also has sufficient strength to provide a load capacity of up to 150kg in standard door and window sizes.

Fixed, arc and multi-sash windows with movable or structural mullion bar, balcony doors with a low aluminium threshold and tilt or lift and slide doors are available. Widths of up to 12 metres and heights up to 2.8 metres as well as non-standard shapes can be accommodated with single or double sash lift and slide doors up to a weight of up to 400 kg.

In terms of design innovation considerable attention has also been paid to external appearance with powder-coated aluminium outer cladding providing a combination of high performance and lasting appearance. The potential to specify the required colour and absence of visible welds at corners provides seamless, contemporary styling.

Products such as Innoview HST doors have virtually no visible while PSK tilt and slide doors provide scope for micro-opening to provide room ventilation without reducing the level of security. Such developments can only provide further incentive to change the face of contemporary fenestration while providing scope to do so in designs up to Passivhaus standard.