Category Archives: Manufacturing

New Condair RS Steam Humidifier

Story

Condair is launching an updated version of its most popular steam humidifier, the Condair RS. As well as a new outer case design, the resistive steam humidifier now incorporates the latest internet-connected technology that allows remote monitoring and troubleshooting by the manufacturer.

Dave Marshall-George, UK & Ireland Sales Director at Condair, comments, “The Condair RS has long been the industry-leading resistive steam humidifier, with its unique scale collector tank allowing easy removal of limescale from the system. Now with Internet-of-Things connectivity, it once again pushes the boundaries of steam humidifier technology. Customers now have the option to have the manufacturer remotely monitor their humidifier’s performance via the Condair Cloud.

“This cutting-edge technology gives customers the peace-of-mind that their humidity control is constantly being managed with the expertise only the manufacturer can provide. With this IoT option, Condair can now support its customers every step of the way, from initial system design, manufacture, supply and install, all the way through to every-day operation and routine servicing.” Dave concludes.

A new touchscreen user interface on the Condair RS operates like a smartphone, in that users can navigate through clear icon-based menus with scroll, slide and press functionality. As well as intuitive control over operation, the controller offers historic performance and settings reporting, service history, error reporting and an Excel-based download to USB function.

Alongside these new features, the Condair RS still incorporates its unique scale management system that has made it so popular. A removeable tank sits underneath the boiling chamber, collecting the scale as it detaches from the heating elements during normal operation. In-house maintenance staff can routinely drain the system and empty the scale from this tank, without opening the main unit housing. This significantly prolongs the periods between major service visits and prevents on-site drainage problems from chunks of scale being sent to drain.

Other innovative features include a “cold-water pool” that prevents any blockages around the water inlet or drain outlet. The boiling chamber has a twin-wall design with the water inlet and drain outlet being situated in an area between these walls. The temperature of this area is kept low enough to prevent scale formation, thus eliminating any possibility of plumbing blockages due to limescale.

The Condair RS range offers comprehensive capacities with sizes to suit any project. Small single cylinder units start with a maximum output of 5kg/h, with double-cylinder models and master/slave configurations offering up to 160kg/h. Steam humidification can be delivered to a duct via a steam lance, as well as directly to a room with a top-mounted or remotely located blower pack.

The Condair Group is the world’s leading specialist in humidity control and evaporative cooling, with energy efficient, hygienic and innovative technologies for commercial, industrial and heritage applications. Condair is represented in the UK by Condair Ltd, which offers system design, manufacture, supply, installation, commissioning, maintenance and spares. You can find out more by visiting the company’s website at www.condair.co.uk.

View Condair's profile:

David Chisnall Joins Condair As Area Sales Manager

Story

Condair has appointed David Chisnall as its new Area Sales Manager for the north of England. David joins Condair with over 25 years’ experience in the HVAC sector, having worked in air filtration and AHU manufacturing sectors.

Dave Marshall-George, Condair’s UK & Ireland Sales Director, comments, “It’s great to have David join the Condair team. He brings a wealth of experience with him, and I’m delighted that he’s now representing Condair in this important sales area covering Yorkshire, Lancashire, Cheshire and some of the surrounding areas.”

David commented, “I’m greatly looking forward to getting to know Condair’s customers and supporting them with their humidity control needs. I’m very happy to be joining the market-leader in the humidity control sector. It’s amazing how many different industries Condair works across, for both humidification and dehumidification, and I’m keen to start engaging with our partners across contractors, consultants, OEMs and end-user clients.”

The Condair Group is the world’s leading specialist in humidity control and evaporative cooling, with energy efficient, hygienic and innovative technologies for commercial, industrial and heritage applications. Condair is represented in the UK by Condair Ltd, which offers system design, manufacture, supply, installation, commissioning, maintenance and spares. You can find out more by visiting the company’s website at www.condair.co.uk.

View Condair's profile:

New Addition To ECO-LOGIC Electronic Controller Range

Story

Main features and benefits of the new ECO-200 Controller Range:

The new ECO-200 range of electronic controllers have been designed to be modular, allowing a mix of different types of touch and non-touch control sensors, switches, relays and solenoid valves. Solenoids and relays of different AC / DC voltages can be used.

The controller can be used, for example, for sanitary ware control in bathrooms to control a basin tap for hot and cold water, a shower and WC. Versions can be supplied to control two bathrooms from one controller.

Due to the modular design of the controller it can be used not only for the ECO-LOGIC range of products for new projects, but to control other makes of sanitary ware control systems were spares are no longer available, which is ideal for maintenance and refurbishment work.

Used with the ECO-LOGIC extra low voltage 6V DC bistable solenoid valves, together with the ECO-LOGIC non-touch sensors, the system provides substantial energy and maintenance cost savings together with a very high standard of Health and Safety for the user and maintenance staff.

The ECO-LOGIC range of electronic controls have now been in the market for in excess of 30 years and therefore we have a wealth of experience of product use in all market sectors in regards to maintenance and life time product operation.

All the ECO-LOGIC range of products are designed and manufactured in the UK.

View ECO-LOGIC UK's profile:

Stelrad Announces First Sale Of Green Steel Compact Radiator

Story

Leading radiator manufacturer Stelrad Radiators has announced its first sale of the brand-new Stelrad Series range. Purchased online, the radiator – the first of many – was picked at the National Distribution Centre and despatched just days after new Stelrad Green Compact went on sale. The purchaser has reported that the selection was driven by a desire to be more eco-friendly and that he was happy to pay a little bit more for a product that will contribute towards lower CO₂ in the atmosphere.

Tata Steel is supplying UK made 90% Carbon Lite steel to Stelrad within the radiator market, so that Stelrad customers can choose a Stelrad Green Compact radiator range that contributes directly to a reduction in atmospheric CO₂ today and accelerates decarbonisation in the future.

Tata Steel is a UK leading strip steel manufacturer with steelmaking facilities in Port Talbot in South Wales. The steel comes with a certificate from DNV – Det Norske Veritas to prove the steel has 90% lower embodied CO₂ emissions. The process for producing the steel is called Optemis® Carbon Lite.

All revenues generated by the process are reinvested to fund additional projects, thereby generating further CO₂ savings to be verified by DNV and speeding up decarbonisation efforts within the UK.

Stelrad’s head of marketing is Chris Harvey: “Whilst largely symbolic, the first sale of any new product is encouraging, and we hope signals the start of an exciting new programme of sales as more and more people wake up to the opportunity to enjoy green steel radiators in their developments and buildings up and down the UK.

“This is an exciting step for us to take towards greener manufacturing and fits in perfectly with our Group’s sustainability policy. The new Stelrad Green Series comprises of 60 horizontal models from our Stelrad Green Compact range. The concept is already being well received by many of our customers who are keen to see more sustainable products being utilised in their homes and buildings. As well as the reduction in carbon emissions, no plastic is being used for the outer packaging either further increasing the sustainability claims of the product range – and of course, a radiator is 100% recyclable.”

To find out more about this exciting new range and the new partnership with Tata Steel, head for www.stelrad.com.

View Stelrad's profile:

Condair Acquires Kuul

Story

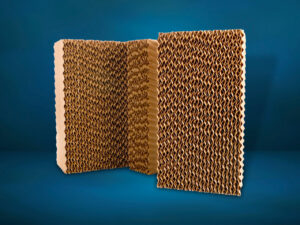

US-based evaporative media manufacturer, Kuul, has been acquired by humidity control specialist, Condair.

Kuul is a leading manufacturer of glass fibre and cellulose media used in evaporative cooling systems and adiabatic pre-cooling for chillers and turbines. Rebranding as Condair – Evaporative Technologies, the organisation will be extending its distribution of evaporative media solutions through Condair’s global network of sales and service offices in 23 countries, and its wider distribution partners around the world.

Oliver Zimmermann, CEO of Condair, comments, “Condair’s mission is driven by our customers’ needs and with the combination of Kuul and Condair, we can meet our customers’ needs even better. Kuul has the media expertise, which perfectly complements the evaporative technology expertise of Condair. Together we can provide reliable and sustainable solutions. With Condair’s global reach, it’s a win-win for both organisations and our customers will benefit from advanced media and system competency from a single partner.”

Alongside the acquisition of Kuul, Condair is also investing in a new production facility in Richmond, Virginia, USA, to strengthen its production capabilities and improve its supply chain efficiency for the key regional US data centre market. The new 400,000ft² facility is planned to open in 2025, and is estimated to employ 180 individuals.

Condair already operates production facilities in Europe, North America and China, and manufactures a comprehensive range of humidification systems. This includes the Condair ME, in-duct evaporative cooling and humidification system, that is used extensively around the world in data centres, offices and industrial manufacturing.

The Condair Group is the world’s leading specialist in humidity control and evaporative cooling, with energy efficient, hygienic and innovative technologies for commercial, industrial and heritage applications. Condair is represented in the UK by Condair Ltd, which offers system design, manufacture, supply, installation, commissioning, maintenance and spares. You can find out more by visiting the company’s website at www.condair.co.uk.

View Condair's profile:

Podcast: How To Select & Size A Commercial Humidifier

Story

Condair has released a new podcast for HVAC professionals on how to select and size a commercial humidifier. In a 15-minute interview with BusinessNet Explorer, Dave Marshall-George, Sales Director at Condair, explains what should be considered when setting out on a humidifier project.

Dave comments, “This podcast will be really helpful for any building services consultant, contractor or FM who needs to understand more about humidification of a commercial premises. Humidifiers are essential in many applications, but projects of this type don’t come along very often. So it can be difficult for HVAC engineers to get the experience needed to successfully design a humidification system. In this podcast, I describe the main elements that determine whether a humidifier should be used in an AHU or directly in a room, which type of humidifier fits what type of application and how to correctly size a unit for an area.”

This latest Condair podcast is available at www.condair.co.uk/podcast as well as on Spotify, SoundCloud and YouTube. Also, available on this Condair webpage is Condair’s back catalogue of podcasts. The series of bite-sized, informative audio episodes cover topics like how to use humidifiers for evaporative cooling in AHUs, how to combat static with humidity, humidity’s impact on health and how to use dehumidifiers to reduce ice in commercial freezers.

The Condair Group is the world’s leading specialist in humidity control and evaporative cooling, with energy efficient, hygienic and innovative technologies for commercial, industrial and heritage applications. Condair is represented in the UK by Condair Ltd, which offers system design, manufacture, supply, installation, commissioning, maintenance and spares. You can find out more by visiting the company’s website at www.condair.co.uk.

View Condair's profile:

Sally Parker joins Condair as Area Sales Manager

Story

Condair has appointed Sally Parker as its new Area Sales Manager for the Midlands and South Wales. Sally joins Condair with a wealth of HVAC experience having worked at ACR wholesaler, TF Solutions, and Wolseley Climate Centre.

Dave Marshall-George, Sales Director at Condair, comments, “We are really delighted to have appointed Sally as Area Sales Manager. She’s a very experienced sales manager with a proven track record in the industry and we feel lucky to have her join us.”

Sally commented, “I’m really looking forward to getting to know Condair’s existing clients and helping new potential customers get to grips their humidity control issues. Condair is well-known as the leading manufacturer in the humidifier sector, with outstanding engineering quality. They operate across so many end-user sectors, it’s really astonishing. I’m keen to get to know all the different industries and start supporting consultants, contractors and FM’s with their humidifier, dehumidifier or evaporative cooling projects.”

The Condair Group is the world’s leading specialist in humidity control and evaporative cooling, with energy efficient, hygienic and innovative technologies for commercial, industrial and heritage applications. Condair is represented in the UK by Condair Ltd, which offers system design, manufacture, supply, installation, commissioning, maintenance and spares. You can find out more by visiting the company’s website at www.condair.co.uk.

View Condair's profile:

New Mobile Humidifier From Condair

Story

Condair is launching the new Condair PureHum 1000 Pro, a mobile humidifier that is ideal for areas up to 1,000m³. Advanced features include phone-based app control, UV-water sterilisation, multiple air filtration options and an 8-speed auto-adjusting fan.

Mobile humidifiers are often used in museums and art galleries, where humidity control can be a temporary requirement during an exhibition period. A mobile humidifier is a great solution, as it is easy to set-up, use and then store when not needed. The Condair PureHum 1000 Pro is ideal for this application, due to its subtle but modern design, tamper-proof control system and lockable castor wheels.

A large 50 litre water tank means the humidifier can be used where there is no available plumbing and won’t require frequent re-filling. A UV-water sterilisation system treats the water with ultraviolet light to kill germs and combat microbial growth. The humidifier can also be plumbed-in with a mains water connection and drain. When plumbed-in, a flushing feature ensures water will not remain in the system to stagnate, further enhancing hygienic operation.

With a maximum output of 2.7 litres per hour, the unit is ideal for a small to medium sized room. A top-mounted touchscreen control panel provides data on current room conditions, water level and operating parameters. A safety glass cover prevents tampering, whilst allowing the screen to be viewed. A remote humidistat sends a wireless signal to the PureHum 1000 Pro, to manage output in line with the desired room humidity level. When multiple units are used across an area, control can be centralised via a single humidistat or managed individually with one humidistat per humidifier.

In addition to the integrated controller, a PureHum app allows users to control the humidifier and see all operating parameters from their mobile phone. Available on the App Store or Google Play, this feature is enabled via an optional WLAN/wifi module.

The Purehum Pro 1000 can offer the additional benefit of air purification as well as humidity control. As standard the unit come with fine dust and F7 air filters. Optionally a HEPA H10 filter can be chosen, which is capable of captures 85% of particles over 0.5 microns in size. Lastly an activated carbon filter can also be employed to remove odours and gases from the air, including volatile organic compounds (VOCs).

The Condair Group is the world’s leading specialist in humidity control and evaporative cooling, with energy efficient, hygienic and innovative technologies for commercial, industrial and heritage applications. Condair is represented in the UK by Condair Limited, which offers system design, manufacture, supply, installation, commissioning, maintenance and spares. You can find out more by visiting the company’s website at www.condair.co.uk.

View Condair's profile:

Stelrad Launches First Ever ‘Green Steel’ Radiator Series

Story

Leading radiator manufacturer Stelrad Radiators is going green with another UK powerhouse Tata Steel to offer the first 90% green steel radiator range. Tata Steel is supplying UK made 90% Carbon Lite steel exclusively to Stelrad within the radiator market, so that Stelrad customers can choose a Green Compact radiator range that contributes directly to a reduction in atmospheric CO2 today and accelerates decarbonisation in the future.

The new Stelrad Green Series comprises of 60 horizontal models from our Green Compact range. The concept is already being well received by many customers who are keen to see more sustainable products being utilised in their homes and buildings. The steel comes with a certificate from DNV – Det Norske Veritas – to prove the steel has 90% lower embodied CO2 emissions. The process for producing the steel is called Optemis Carbon Lite. As well as the reduction in carbon emissions, no plastic will be used for the outer packaging either further increasing the sustainability claims of the product range – and of course, a radiator is 100% recyclable.

Customers purchasing a green radiator from the new Stelrad Green Series will be saving the equivalent expenditure of driving a small car over 250 miles per radiator purchased.

To find out more about this exciting new range and the new partnership with Tata Steel, head for www.stelrad.com.

View Stelrad's profile:

Podcast: How To Control Static By Controlling Humidity

Story

In this short interview with Business Net Explorer, Dave Marshall-George, Sales Director at Condair, explains why static build-up occurs at low humidity, the issues it can cause in industrial and commercial situations, and how best to control it through humidification of the indoor environment.

Dave comments, “Electrostatic build-up is much more prevalent as indoor relative humidity drops. This means it can be seasonal issue for manufacturers. Indoor humidity is lowest in the winter, so manufacturers can experience increased problems of materials sticking together, being repelled by each other, or even sparks resulting from electrostatic discharge, during the colder months. A very effective way of dealing with this is to raise the indoor humidity to around 45%RH.

“Studies have shown that at higher levels of indoor humidity, the static charge caused by activities, such as walking across synthetic carpets, can be reduced by as much as 95-98%. This short podcast explains why and how manufacturers and facility managers can use humidity control as an effective anti-static measure.”

The podcast is available all major podcast channels, including Soundcloud, Spotify and Google Podcast by searching for “Condair” and also on the Condair website at www.condair.co.uk/podcast.

The Condair Group is the world’s leading specialist in humidity control and evaporative cooling, with energy efficient, hygienic and innovative technologies for commercial, industrial and heritage applications. Condair is represented in the UK by Condair Ltd, which offers system design, manufacture, supply, installation, commissioning, maintenance and spares. You can find out more by visiting the company’s website at www.condair.co.uk.