Category Archives: Manufacturing

ISO specification fastener in Stainless Steel

Story

Precision Technology Supplies Ltd, are now holding stock of a wide range of the new ISO specification fasteners in Stainless Steel. The changes are causing some confusion with customer., However PTS have taken great care to ensure they make the changes as smooth as possible. PTS will also continue to hold stocks of the previous Din/ISO versions as customer requirements for these parts continue. If you have a requirement for ISO specfifcation fasteners in Stainless Steel, or are unsure which version you require, give us a call we will be happy to assist.

View Precision Technology Supplies's profile:

Saniflo supplies London landmarks

Story

Saniflo – inventor of the macerator and sixty years later still the UK’s number one supplier – continues to ensure that the capital’s prestigious educational establishments and iconic landmarks are able to run smoothly and provide their customers with a wide range of facilities. The City of London University Northampton Square, The Shard, The Walkie Talkie, The Excel Centre, Canary Wharf and Curzon Street have all recently called on Saniflo to solve a plumbing challenge.

At the City of London University Saniflo units have been installed to help create additional science laboratories, accommodation and washroom facilities in a semi-basement on the lower floors of the building, and all without interrupting the daily functioning of the facility.

Working with Aveat Heating of Essex, Saniflo has supplied 12 Sanicubic 2 Pro macerating pumps, several Sanispeed pumps and Sanibest macerators to discharge waste in areas of the University where continuity of service is critical.

The Sanicubic 2 Pro features dual pumps so that in the unlikely event of a pump failure the other kicks in as a back-up whilst a warning alarm sounds highlighting the need for attention. The Sanicubics quietly discharge waste through 50mm discharge pipes that join up to meet the mains drains and are capable of linking a number of WCs plus multiple grey water producing appliances. They can also be connected to Building Management Systems for even greater control.

Sanispeed pumps have been installed in the student kitchen areas to clear waste water and Sanibest macerating units are now operating in the ladies and gents toilets in the labs.

The Shard was created using pioneering engineering methods not previously used in the UK involving top-down methods where foundations are dug while the core is built up. Officially completed and opened in 2012, The Shard – formerly Southwark Towers and home of PwC – is today an architecturally striking vertical building housing multiple and varied occupiers including hotel, education, medical, tourist, residential, retail, restaurant and office facilities. Here, a total of 45 Sanispeed units help to keep prestigious medical facilities of London Bridge Hospital fully functioning.

20 Fenchurch Street – otherwise known as The Walkie Talkie – with its top-floor Sky Garden, which was completed in 2014 and is the sixth tallest building in The City of London. The 34-storey building cost more than £200 million to complete and today features a highly distinctive top-heavy form, which appears to burst upward and outward. This building uses Saniflo macerators and pumps on every floor to ensure it can remain open for business. Sanispeeds are being installed on each of the 25 floors, replacing a competitive unit that was holding too much water and creating bad smell problems. The units are used in kitchenettes, which have a couple of sinks. The project was assessed on-site by Saniflo technical team, who recommended the Sanispeed along with a number of powerful Sanicom pumps, which have the capacity to handle hot water for extended periods of times. The plumbing goes up into the ceiling to the main stack pipe and this connects to mains drains serving the whole building.

ExCeL London first opened in November 2000 and is still growing today with additional facilities being added. The 100-acre site at Royal Victoria Dock is home to many large events including exhibitions and conferences and millions of people visit ExCeL every year. This prestigious venue relies on a number of Saniflo Sanicubics which were installed to provide additional guests toilet facilities as footfall increases.

At Canary Wharf a Sanicom2 and Sanicubic 2 Pro are being installed in new shower rooms and a canteen area to provide staff facilities at the offices of a National newspaper and at Curzon Street Saniwalls are being installed into the bathrooms and en-suites of an apartment block above a restaurant. The building is being renovated but, because of the restaurant, the floor below cannot be excavated for alternative drainage. The only way of pumping waste and water out of the multi-million pound properties is via the proven Saniflo pumps.

Saniflo macerators and pumps are designed to solve the toughest and most complex plumbing situations and with this year’s new product launch – the biggest in the company’s history – no project is too big or small for Saniflo.

View Saniflo's profile:

Wakaflex lead-free flashing for ultimate performance

Story

Flashing work often requires a specialist roofer and can be both time-consuming and costly. Leadwork is also potentially hazardous to the installer if strict health and safety procedures aren’t adhered to.

This has prompted the introduction of a host of lead-free flashings, Klober Wakaflex® being both one of the longest established and highest performing. BBA-certified and with a 20-year guarantee, it is ideal for all roofing abutment work and roof types including clay, concrete, slate, metal and polycarbonate. Available in, light grey, anthracite, brown and terracotta (the latter two to special order), it has an aluminium ‘honeycomb‘ mesh embedded into UV-resistant butyl rubber which gives the product similar malleability to lead but with no scrap value. Unlike lead, it can be stretched by up to 50% in length and 15% in width and with no susceptibility to thermal movement it can also be laid in long lengths without fixing clips. With no need for forming or other specialist tools Wakaflex provides lasting performance regardless of detailing complexity and can be shaped around deeply profiled tiles or seal the top saddle and roof penetrations.

Wakaflex has a high-strength, self-adhesive Butylon® backing which provides immediate weatherproofing and on laps will also chemically bond to itself to provide a totally secure seal. It is environmentally safe, presents no contamination problem with water run-off and can therefore be used with rainwater harvesting systems.No heat, solvents, adhesives or other additional means of fixing are needed and installation can take place in temperatures from minus 40 – 100⁰C, normally without priming.

Wakaflex is available from builders and roofing merchants nationwide.

http://klober.co.uk/shop/product/wakaflex

View Klober's profile:

VMZINC launches Basic Competency Programme

Story

The continuing upsurge in use of zinc as a roofing and façade material has led VMZINC to introduce a ‘Basic Competency’ (BCP) training programme. Organised in conjunction with the CITB, Roofing Industry Alliance and FTMRC, the single-day module is linked to NVQ Level 2 and equates to the first stage of formal installer accreditation. Elements covered include roof design and construction, fitting, maintenance, tools, ancillaries and soldering. On achieving a ‘Pass’ an individual becomes eligible for a Red ‘Experienced Worker’ CSCS card if he has a ‘Working at height’ HSE test certificate. The holder has three years to register with a training provider to work towards NVQ and eligibility for a blue ‘Skilled Worker’ card. For details email vmzinc.uk@vmzinc.com or phone 01992 822288.

View VM Zinc's profile:

Saint-Gobain PAM – Better BIM Data from Collaboration

Story

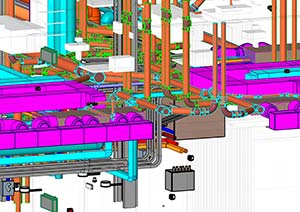

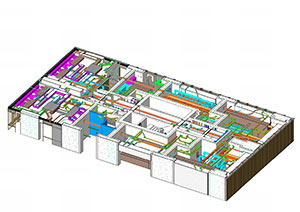

Saint-Gobain PAM has further developed its BIM library for its cast iron sanitary, soil and rainwater systems following collaboration with Hoare Lea.

Says Matthew Hassall, BIM Implementation Manager for Saint-Gobain PAM, “Ultimately BIM is only as good as the data that the manufacturer or supplier provides. It is now 12 months since BIM has had to be implemented on public sector projects and as a result industry is learning exactly what it wants from a library of products and systems. And the only way of achieving this is to collaborate with the supply chain and ask it what it needs and equally as important what is not required.”

Says Bogdan Pop, Public Health Engineer from Hoare Lea who has been collaborating on the company’s BIM development, “From our point of view we need to work with a manufacturer’s data, generic libraries just do not work. This in turn means that we need to work closely with suppliers like Saint-Gobain PAM to define exactly

what we need and to also remove unnecessary information.

“One very practical issue that we have come across relates to the software platform that many BIM libraries use. If a manufacturer does not put constraints on the dimensions of their products, then in theory you can design whatever you want; the problem is the design you have put together may include products that don’t exist in reality!

“Equally manufacturer’s mistakenly believe that they should include every detail in their 3D drawings, where often all we need are the dimensions. It means that the 3D drawings can be so large that it takes time to download and then input them into a design.

Continues Hassall: “BIM encourages us to share data, but the better question is defining exactly what data you need. We also recognise that these needs will evolve over time so on going dialogue with the supply chain is vital.”

Concludes Pop, “Developing a BIM library takes time and resource, sadly too many manufacturers have not invested and this only creates problems for the designer, installer and ultimately the final customer.

There is a real difference between the theory and what is actually effective when it gets down to working on a project.”

View PAM Building's profile:

Bona Titan – a new generation of powerful adhesives

Story

Bona, the wood floor experts, has launched Bona Titan, a new supreme performance, silane- based adhesive for high value projects, very wide or oversized solid wood boards – or any installation where the quality of the bond has to be guaranteed.

Bona Titan contains Titanium Technology – a revolutionary new formula comprising quadruple crosslinking that delivers superior durability and an unbeatable initial bond speed – even under challenging subfloor conditions.

Bona Titan can be specified with confidence to bond all types of wood flooring. Its superb shear strength makes installation easy and keeps even the largest, solid boards securely in place. If the subfloor is sound and dry, no primer is required.

The hard, silane-based formula contains no ingredients that can migrate after curing, which eliminates all risk of discolouration at the joints. The smooth, thick consistency makes it easy to use and produces stable ribs, an extremely high initial grab and zero risk of hollow spots. The bond strength of Bona Titan will not diminish over time so the stability of the floor is guaranteed for the long term.

Bona Titan meets ISO 17178 standards and, in line with Bona’s environmental strategy, is a safe, clean formulation which also carries EC1-R Plus, DIBt, Greenguard and A+ low emission certifications.

Bona Titan is compatible with underfloor heating and can be used directly on metal or tiles. Floors bonded with Bona Titan can be sanded after just 12 hours.

Further technical information is available at bona.com or from Bona’s technical department on 01908 525 161.

View Bona's profile:

Condair opens new Hamburg factory

Story

Global humidifier specialist, the Condair Group, has recently opened its newly built production, logistics and sales facility in Hamburg, Germany, marking a milestone in the company’s development. The state-of-the-art 13,000m² building centralises Condair’s European manufacturing operations, previously carried out in four regions across the continent.

Situated next door to Hamburg airport, the new Condair facility is also close to the motorway and harbour, and incorporates the latest in energy saving building services technology.

Oliver Zimmermann, Condair’s CEO, explains, “Norderstedt in Hamburg offered us the perfect logistical location. Placing our production facility close to our core central European markets, with such convenient transport links, shortens our delivery channels and results in quicker delivery times. The consolidation of four different European production centres into a new high-tech facility not only makes Condair more streamlined and cost-effective but also enables us to improve our processes and quality.

“The excellent opportunities offered by the new location are essential for the far-reaching restructuring of the company and it is with great pride that we open this new chapter in the Condair success story.”

Central to the design of the Condair building was a focus on energy saving technology. The German Energy Saving Ordinance (EnEV) 2014 and a maximum heat demand of just ≤35 kWh/(m²·a) were selected as minimum standards for the building. Once completed, the building actually performed 50% better than the target standard and almost achieved Passive House standard at full capacity, which is an outstanding result for a production facility with offices.

Geothermal power is harnessed through the use of two 28m high-performance energy piles, and roof-mounted photovoltaic panels generate nearly all the required electrical energy for the site. A hybrid ceiling system, from the sister company Barcol-Air, provides cooling and heating, as well as acting as a thermal storage system in combination with the building shell.

Being the world leading humidification specialist, maintaining a healthy indoor climate of 40-60% relative humidity at 22-26°C was of utmost importance for the Condair development. Humidity control is primarily delivered using a Condair GS, gas-fired steam humidification system, with energy being transferred from its flue gases to the incoming fresh air via a heat recovery system for improved efficiency. A Condair ME evaporative humidifier is providing indirect evaporative cooling by humidifying the exhaust air and pre-cooling the incoming fresh air by several degrees with a heat recovery system. Other direct room humidifiers are also providing localised humidity control and evaporative cooling around the building.

The current internal conditions are presented for all to see on a digital wall display, which also shows the atmospheric conditions at all of Condair’s 16 other international offices around the world. This is part of the “learning zone“ at the facility that allows visitors to explore the complex nature and importance of humidity control within the modern indoor environment. Alongside video walls and demonstration areas there is a full size air handling unit with internal holographic representations, showing how each type of humidifier technology operates and conditions the air stream in various HVAC scenarios.

Condair Group is the world’s leading specialist in humidification and evaporative cooling, with energy efficient, hygienic and innovative technologies for commercial, industrial and heritage applications. Condair is acting directly in the UK through Condair plc, which offers system design, manufacture, supply, installation, commissioning, maintenance and spares. Condair in the UK is the new name for JS Humidifiers following the organisation’s rebranding in October 2014.

View Condair's profile:

Podcast Now Available: BNE Product News – Liam Williamson of Guardian Glass interview at Materials 2017

Story

Liam Williamson is Marketing Manager for Guardian Glass. In this interview at Materials 2017, he explains why Guardian Glass chose to exhibit at the show and what visitors to the Guardian Glass exhibition stand could expect to see plus how specifiers viewing this podcast can easily contact the brand for more information. The interviewer for BusinessNet Explorer is Mick de Leiburne.

Click to play interview on YouTube

View Guardian Glass's profile:

Podcast Now Available: BNE Product News – William Rodriguez-Lopeth of Cromocon interview at Materials 2017

Story

William Rodriguez-Lopeth is Sales & Marketing Representative for Cromocon. In this interview at Materials 2017, he explains why Cromocon chose to exhibit their portable meter for Colour Measurement and Light Reflectance Value (LRV) at the show and what visitors to the Cromocon exhibition stand could expect to see plus how specifiers viewing this podcast can easily contact the brand for more information. The interviewer for BusinessNet Explorer is Mick de Leiburne.

Click to play interview on YouTube

View Cromocon's profile:

Podcast Now Available: BNE Product News – Jason Hughes of Imperial Bricks interview at Materials 2017

Story

Jason Hughes is MD for Imperial Bricks. In this interview at Materials 2017, he explains why Imperial Bricks chose to exhibit at the show and what visitors to the Imperial Bricks exhibition stand could expect to see plus how specifiers viewing this podcast can easily contact the brand for more information. The interviewer for BusinessNet Explorer is Mick de Leiburne.

Click to play interview on YouTube