Category Archives: Manufacturing

Second Queen’s Award presentation in three years for Ancon

Story

Just three years after its first Queen’s Award for Enterprise presentation in 2012, Ancon Building Products officially received its second award on Thursday 15th October at a special ceremony at its manufacturing site in Deeside, North Wales.

Just three years after its first Queen’s Award for Enterprise presentation in 2012, Ancon Building Products officially received its second award on Thursday 15th October at a special ceremony at its manufacturing site in Deeside, North Wales.

The 2015 Award, for International Trade, recognises Ancon’s outstanding success in growing sales across new and existing export markets. It follows the company’s previous Queen’s Award for Enterprise in Innovation for its ground-breaking Lockable Dowel, a system that has since revolutionised post-tensioned concrete construction.

The prestigious award, the highest accolade that any UK business can achieve for export growth, was presented to Ancon by the Lord Lieutenant of Clwyd, Mr Henry George Fetherstonhaugh OBE, on behalf of Her Majesty the Queen.

The ceremony at the Deeside facility, the largest and most advanced Wall Tie manufacturing operation in the UK, was attended by 36 employees who proudly watched Ancon’s Export Team Leader, Angela Reeve, accept the ceremonial scroll from the Lord Lieutenant. Her colleague Lynn Forster, Deeside’s Purchasing Manager and longest-serving employee at the site, who has been part of the Ancon team there for the last 32 years, received the commemorative Queen’s Award crystal bowl on behalf of the company.

The Lord Lieutenant said,

“Ancon represents the very best of British innovation and technology, and this dynamic company, which has trebled its exports in the last ten years, has led the way in its field.”

“To win one award is pretty spectacular; to win two awards in three years is absolutely amazing.”

“It is very gratifying to present this award here in Deeside, where Ancon provides 92 much needed jobs and I wish the company every continued success in the future.”

In addition to its headquarters and two manufacturing sites in Sheffield, South Yorkshire, Ancon has operated production facilities in North Wales since 1983. The Lord Lieutenant met several employees as he toured the site on Deeside Industrial Park, where the company has been based since 2008 when they outgrew previous sites in Flint and Greenfield.

Speaking after the ceremony, Managing Director, Stuart Maxwell said,

“It’s another very proud day for the Ancon business. We now hold Queen’s Awards for both Innovation and International Trade, confirming that we are successfully combining the development of market-specific solutions with effective worldwide distribution strategies. Our UK-manufactured products are now exported across the globe from the USA, Russia, throughout the far east and into the Asian pacific regions.”

“Our outstanding achievements over the last few years are down to the knowledge, hard work and commitment of our employees, as well as our distributors around the world. My sincere thanks and congratulations go out to everyone.”

“With a number of major construction projects and new product launches in the pipeline, I am certain the business will continue to go from strength-to strength.”

View Ancon's profile:

Growth set to continue at Crittall as new MD takes the reins

Story

An executive with more than two decades’ experience in the construction products market, and who believes in ‘leading from the front’ has been appointed Managing Director of Crittall Windows.

An executive with more than two decades’ experience in the construction products market, and who believes in ‘leading from the front’ has been appointed Managing Director of Crittall Windows.

Stuart Judge has joined the Witham-based company, the world’s oldest continuous manufacturer of steel windows, from Everest, where he was commercial director.

He takes over the helm at Crittall from John Pyatt who has been MD for the past 16 years. Pyatt now becomes company chairman.

Judge has been a prominent figure within the construction and industrial products market for the past 21 years having also worked for Mumford & Wood, Blairs Ltd and Saint-Gobain Solaglass. He joined industry following five years in the Royal Navy as a marine electrical engineer.

He says: “l believe that leading from the front, by example, and passionately demonstrating vision, are some of the key facets to building and enhancing strong, team based cultures.”

Pyatt, announcing his decision to relinquish the MD’s role explained:

“Following 16 years as Managing Director I feel it is now time to hand over the reins. During my stewardship the Company has been through some difficult and challenging times and we have been able to successfully navigate our way into a much stronger and resilient business which provides the stepping stone for a further development.”

Welcoming Judge’s appointment he added: “Stuart is a senior, highly experienced sales and commercial leader with 21 years of achieving results and success in the construction market, many of them in the window industry. Crittall will go from strength to strength under his management.”

View Crittall's profile:

PTS publish new product catalogue

Story

Precision Technology Supplies are pleased to announce the publication of a new 500 page product catalogue. The catalogue covers the full range of Metric and Unified Stainless Steel Fastener we can offer. We have been working on our e-catalogue for a long time and this has been very successful, however we felt it was time to produce a hardcopy version. The catalogue will be available in English as a hardcopy and online in 5 different languages. To request a copy or to download the e-catalogue please visit our website www.pts-uk.com or email us at sales@pts-uk.com

Precision Technology Supplies are pleased to announce the publication of a new 500 page product catalogue. The catalogue covers the full range of Metric and Unified Stainless Steel Fastener we can offer. We have been working on our e-catalogue for a long time and this has been very successful, however we felt it was time to produce a hardcopy version. The catalogue will be available in English as a hardcopy and online in 5 different languages. To request a copy or to download the e-catalogue please visit our website www.pts-uk.com or email us at sales@pts-uk.com

View Precision Technology Supplies's profile:

New video highlights how to reduce energy in your building

Story

A new video from Mitsubishi Electric shows how the company took its head office from an ‘E’ to a ‘B’ energy rating and offers advice on how other companies can do the same.

A new video from Mitsubishi Electric shows how the company took its head office from an ‘E’ to a ‘B’ energy rating and offers advice on how other companies can do the same.

With tough legislation focusing attention on energy use in the built environment, how we heat, cool and ventilate our buildings is coming under scrutiny as never before.

“We’ve been on an eight year journey and one of the things we are saying in this video is that any business could and should be planning to improve the performance of their building”, explains Russell Jones who hosts the video.

“Just like any other company we have had to make a strong business case for each new piece of equipment, but the fact that we have improved so much and have significantly reduced running costs shows the advantages that can be gained”.

The video can be viewed on the company’s dedicated YouTube channel: https:youtube.com/mitsubishielectric2

View Mitsubishi Electric's profile:

Saint-Gobain PAM UK launches new VortX range of steel channels, gullies and gratings

Story

Saint-Gobain PAM UK, part of international materials company Saint-Gobain, has launched a new range of steel channels, gullies and gratings for use in most industrial and commercial applications.

Saint-Gobain PAM UK, part of international materials company Saint-Gobain, has launched a new range of steel channels, gullies and gratings for use in most industrial and commercial applications.

Adding to the company’s VortX range of cast iron floor, roof and shower drains, the steel channels, gullies and gratings can be used internally and externally and are 100% recyclable at the end of product life.

Supplied in Grade 304 stainless steel as standard with Grade 316 versions also available, products are designed to suit terrazzo, tiled and vinyl floor finishes. Grating options include a high flow, anti-slip bar grate, ideal for areas where more slip resistance is required, and can withstand loads of 15kN to 250kN.

Commenting on the launch, Mike Rawlings, Marketing Manager – Soil, Drain & Rainwater at Saint-Gobain PAM UK said:

“This launch adds to our ever-growing VortX range, which is the result of a continuous development programme that offers installers everything they need to do the job, without complicated selecting procedures.

“The standard range is suitable for a number of applications including food and drink processing, pharmaceuticals, commercial kitchens, hotels and restaurants, hospitals, supermarkets, sports and leisure, prisons, railways and utilities.

“In addition to the standard products in the range, we can offer an array of bespoke products that can be manufactured to suit the customers’ exacting requirements.”

For more information, visit www.pam-vortx.co.uk or telephone 0115 930 5000 to request a brochure.

View PAM Building's profile:

Nortek Global HVAC Launch Their First Packaged Heating AND Cooling Unit

Story

Nortek Global HVAC, the UK’s leading supplier of gas-fired warm air heating and ventilation systems, has launched its first packaged HVAC unit.

Nortek Global HVAC, the UK’s leading supplier of gas-fired warm air heating and ventilation systems, has launched its first packaged HVAC unit.

Reznor’s P125 is a packaged unit that provides heating, cooling and ventilation for commercial and industrial applications. The unit provides a complete standalone solution for clients requiring energy efficient cooling and heating systems with the ability to provide fresh air and extract air solutions, ensuring a very high standard of indoor air quality.

The P125 is so versatile that it can be used in a number of commercial and industrial applications including, restaurants, cinemas, events centres, arenas, showrooms, exhibition centres and shopping centres as well as distribution centres, warehouses and high-tech production facilities.

This innovative product from Reznor combines many energy saving features to provide class leading performance including modulating heating and cooling to provide accurate and proportional temperature control, variable speed fans to balance and control the airflow, along with heat recovery options with high efficiency thermal wheel and dehumidifying pumps.

Benefits

“For improved effectiveness and in order to maintain comfort conditions within a building along with air quality and humidity, an efficient HVAC system must be able to deal with all climatic variables. Reznor’s range of rooftop units comprising models YDSA, YDHA and YDMA have all been developed with these factors in mind” says Steve Walford, Product Manager. .

The P125 is difference to its adversaries in that it has the ability to provide solutions for between 0 – 100% fresh air. Models YDMA 70 – 100%, YDHA 30 – 70% and model YDSA 0 – 30% fresh air. The unit meets environmental concerns by offering free cooling 0 – 100% using fresh air to reduce energy consumption by the compressors and features a digital scroll compressor with 10% to 100% capacity control to reduce running costs and provide accurate temperature control. There is also a variable air volume (standard) plug fan technology on all models, which reduces fan power for demand control ventilation.

A high efficiency integrated energy recovery (thermal) wheel is available on all models along with 10 – 100% gas modulation for close temperature control and reduced heating costs. The product also features a reheat pump option for superior part load performance.

Added to their existing portfolio of industry leading products, the P125 reinforces Reznor’s position as leaders in the manufacture and development of energy saving products.

View Reznor's profile:

Precision Technology Supplies announce move to new larger premises in East Grinstead.

Story

Precision Technology Supplies, the East Grinstead Based Stainless Steel fastener distributor, are pleased to announce we will be moving to a new larger warehouse in the next few weeks. Continued growth and the need for larger stock holding have meant we have outgrown our current facility despite recent extensions and modifications. The new 30,000 sq/ft warehouse will allow for continued growth for the foreseeable future. Extra storage will mean increase stock holding allowing us to provide more items from stock. The new facility is located on the same industrial estate as the current warehouse providing a seamless change from one place to another with no disruption to service levels.

Precision Technology Supplies, the East Grinstead Based Stainless Steel fastener distributor, are pleased to announce we will be moving to a new larger warehouse in the next few weeks. Continued growth and the need for larger stock holding have meant we have outgrown our current facility despite recent extensions and modifications. The new 30,000 sq/ft warehouse will allow for continued growth for the foreseeable future. Extra storage will mean increase stock holding allowing us to provide more items from stock. The new facility is located on the same industrial estate as the current warehouse providing a seamless change from one place to another with no disruption to service levels.

View Precision Technology Supplies's profile:

HIGH EFFICIENCY SMALL CIRCULATORS – Is ErP Legislation working?

Story

European legislation has its friends and its enemies as we have discovered, having survived the rigours of a recent General Election. Whatever the outcome of the promised referendum on EU membership here in the UK, we have to get on with abiding by European Directives for now. With many of the day to day products in use in the heating and plumbing sector being manufactured by European companies, it seems highly likely that with much of the legislation already in place and being acted upon, it would stay whatever the outcome. In the EU, or out, we clearly as a nation, need to reduce carbon emissions and continue to clean up our act on the environmental stage.

European legislation has its friends and its enemies as we have discovered, having survived the rigours of a recent General Election. Whatever the outcome of the promised referendum on EU membership here in the UK, we have to get on with abiding by European Directives for now. With many of the day to day products in use in the heating and plumbing sector being manufactured by European companies, it seems highly likely that with much of the legislation already in place and being acted upon, it would stay whatever the outcome. In the EU, or out, we clearly as a nation, need to reduce carbon emissions and continue to clean up our act on the environmental stage.

There is still a lack of realisation in some circles, of the amount of energy that is used day to day by pumps as a proportion of energy use in the average home. And every home pretty much, has one. Once understood, it’s easy to see why it was a prime area for attention when looking for ways of reducing energy use and reducing carbon emissions. In today’s vernacular, it was something of a ‘no brainer’.

Small circulating pumps are a key component of all wet heating systems in the UK – whether traditional boiler driven systems or new renewable systems. They perform as standalone pumps or as integrated pumps in combi and system boilers and they keep the water circulating in underfloor heating systems too. They are responsible for a much higher percentage of overall household electricity usage than many still realise which is why old uncontrolled pumps were targeted by European legislation as a key way of reducing energy usage in the home, reducing energy bills and reducing emissions. They offered a real way of making strides towards meeting the ambitious environmental targets set by the UK Government and European legislators.

Small circulating pumps are a key component of all wet heating systems in the UK – whether traditional boiler driven systems or new renewable systems. They perform as standalone pumps or as integrated pumps in combi and system boilers and they keep the water circulating in underfloor heating systems too. They are responsible for a much higher percentage of overall household electricity usage than many still realise which is why old uncontrolled pumps were targeted by European legislation as a key way of reducing energy usage in the home, reducing energy bills and reducing emissions. They offered a real way of making strides towards meeting the ambitious environmental targets set by the UK Government and European legislators.

Before January 2013, small circulating pump selection was often made on price. Although some installers had loyalty to a brand, in many people’s eyes, a pump was a pump was a pump. If it did the job, it did the job. There were a few high efficiency pumps on the shelves before the end of 2012, but at a far higher price than the standard efficiency ones. Until legislation said that you had to install them, despite some installers deciding that a high efficiency pump was what the customer deserved as part of an energy efficient heating system, from sales figures alone, it was clear that many were voting with their wallets.

From January 2013 high efficiency pumps were demanded by EU Legislation – the much vaunted ErP Legislation – and whilst there was initially some resistance to comply, as 2013 unfolded and availability of anything other than high efficiency options declined, installers began to buy and install and specifiers began to specify the high efficiency options. Now, just a few months down the line, high efficiency pumps have been accepted and are being installed in their thousands across the UK, with for example, some social housing landlords undertaking major pump replacement programmes, to help reduce their tenants’ electricity bills.

From January 2013 high efficiency pumps were demanded by EU Legislation – the much vaunted ErP Legislation – and whilst there was initially some resistance to comply, as 2013 unfolded and availability of anything other than high efficiency options declined, installers began to buy and install and specifiers began to specify the high efficiency options. Now, just a few months down the line, high efficiency pumps have been accepted and are being installed in their thousands across the UK, with for example, some social housing landlords undertaking major pump replacement programmes, to help reduce their tenants’ electricity bills.

Despite this embracing of the new legislation and availability of the new ErP compliant circulating pumps, the fact remains that there are still many millions of old, uncontrolled small circulators operating in heating systems across the UK. So there is still huge potential to further reduce energy use and energy bills in the months and years ahead. Wilo and other pump manufacturers have begun to see their high efficiency models begin to sell well. Helped by the legislation, there was little choice but to utilise the new high efficiency models.

Although the concept of lifecycle costs was not new in January 2013 when ErP came into force, it was a concept that had largely been associated with commercial projects rather than domestic ones. But suddenly it became more important and the additional costs that inevitably follow the development of exciting new technology – in this case the vastly improved electronics and the arrival of electronically commutated motors (ECMs) for small circulating pumps – were justified by the lower life cycle costs of the new high efficiency, more expensive pumps and the huge savings possible over a ten or fifteen year operational life time. These could pay for the increased capital cost of the pump at the outset, many times over.

Wilo has just announced it is celebrating the sale of 28 million small circulators in the past ten years. In addition the company recently celebrated the selection of its small circulators as the pumps in the new combi boilers launched by two major boiler manufacturers here in the UK. Wilo’s high efficiency small pumps – in particular the Wilo-Yonos PICO – have made a huge impact in the UK heating and air conditioning sector over the past two and a half years, since the arrival of the ErP legislation in January of 2013.

Wilo’s series of glandless pumps – Wilo-Yonos PICO, Wilo-Stratos PICO and Wilo-Stratos – are seeing increasing popularity across the board. They are relevant for nearly all applications for heating, air-conditioning and cooling in the building services area – from the family home to a small commercial or industrial building.

Sadly, as always, some people will try to circumnavigate new legislation and ignore the drivers for environmentally friendly products. There has been genuine concern in the pump industry about the on-going availability of non-ErP compliant pumps, and the mislabelling of some pumps being imported into the UK and European markets since January 2013. European manufacturers are concerned that these pumps, although cosmetically looking like the new high efficiency models, in some cases, do not meet the requirements of the ErP regulations. Wilo, along with fellow members of the British Pump Manufacturers Association, continues to monitor this situation and report breaches of the regulations to the relevant authorities.

In general terms, the arrival of the EU ErP Directive has clearly begun to make significant inroads in the energy consumption figures, and as a result the emissions figures. There’s a long way still to go to hit the targets being demanded. But the age of the energy efficient pump is very much here.

To find out more about Wilo’s highly convenient, reliable family of high efficiency, ErP compliant small circulating pumps, just click on to www.wilo.co.uk.

View Wilo's profile:

Timbmet builds for the future

Story

The Timbmet Group has had a second consecutive year of improving both their gross and net profitability and stabilising revenues. To build on the secure business platform now in place, Timbmet is planning for further growth.

The Timbmet Group has had a second consecutive year of improving both their gross and net profitability and stabilising revenues. To build on the secure business platform now in place, Timbmet is planning for further growth.

Chairman, Simon Fineman, comments: “The Group is pleased to report an operating profit before exceptional costs of £2.126 million, compared with £1.782 million last year. Given the actions taken by the group in recent years and the future plans, both supported by an easing of economic pressures, the board are confident that the business will continue to grow and to trade profitably in the current financial year.”

The decisive action in the first half of 2013 to restructure the management team and certain operational elements of the business has been reflected in the results for the last two years.

UK Managing Director, Nigel Cox, reports: “The underlying trend for the UK business was an increase of 7.1%, with our overseas business showing a strong growth of 31.1%. Overall, group sales fell by 1.0%, but this includes the discontinuation of low margin direct business to a major DIY chain. As a result, the gross profit percentage increased by 1.7 percentage points.

“Our intention now is to invest further by enhancing our stock range and increasing the number of front line sales staff so that customers get the advice and support that they need. Operationally we’re investing in our business infrastructure, expanding our warehouse capabilities and upgrading our fleet to enable us to effectively process the orders and, ultimately, deliver the product.”

Chief Executive, Paul Rivers, notes: “It is very pleasing to see the efforts of the last two years reflected in the group’s return to stability and profitability. We are continuing to work on forward planning to continue increasing the rate of sales growth and profitability of the business. This will in turn allow for greater re-investment for the future.”

Paul continues, “We want to be a business that customers want to trade with, because our service is better, our products are right and because our staff understand what the customer needs.”

Timbmet has also continued to review their closed final salary pension scheme. This year an additional non-cash exceptional cost of £1.0 million was recognised to correctly equalise retirement ages under the scheme. The 2014 triennial valuation of the scheme has been completed, and a new and longer deficit reduction payment plan will apply from July 2015. This will reduce the group’s contributions to the scheme for the next three years.

View Timbmet's profile:

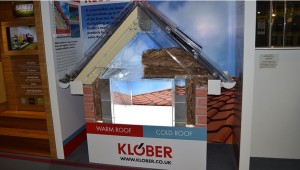

Klober airtightness accessories at the Building Centre

Story

For those designing energy-efficient buildings, roofing specialist Klober now has a permanent exhibit at the Building Centre. Klober has pioneered the development of tapes, sealants, sealing collars and vapour control layers to seal the roof space, ceilings and tile penetrations. The company also manufactures high performance air-open and vapour permeable underlays for all roof types and pitch in order to provide balanced ventilation and airtightness. As with all exhibits at the Building Centre, brochures are available on site or via Specifinder – http://tinyurl.com/p4mjgmz. A roofing airtightness CPD presentation can also be booked by calling Ann Leeson on 01332 813060.

For those designing energy-efficient buildings, roofing specialist Klober now has a permanent exhibit at the Building Centre. Klober has pioneered the development of tapes, sealants, sealing collars and vapour control layers to seal the roof space, ceilings and tile penetrations. The company also manufactures high performance air-open and vapour permeable underlays for all roof types and pitch in order to provide balanced ventilation and airtightness. As with all exhibits at the Building Centre, brochures are available on site or via Specifinder – http://tinyurl.com/p4mjgmz. A roofing airtightness CPD presentation can also be booked by calling Ann Leeson on 01332 813060.