explore the BusinessNet

Marshall-Tufflex GRP trunking keeps rail station renovations on track

Story

With more than 200 million passenger journeys a year, durability and ease of installation were key considerations for contractors leading a multi-million pound upgrade of a high profile UK rail station.

Rail projects have some of the most challenging cable management requirements due to the harsh, and sometimes hazardous, environment of their locations. With its lightweight construction, long life span and resistance to fire and corrosion, Marshall-Tufflex’s Glass Reinforced Polyester (GRP) cable management system provided the perfect solution.

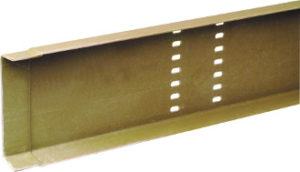

More than 700m of perforated GRP tray with standard covers has helped deliver power and data provision for station signalling, lighting, tannoys and surveillance systems. The installation formed part of renovations to bring old platforms back into use and extend current platforms to accommodate longer trains.

GRP is the material of choice for a wide range of cable management projects in the rail network. The robust product is specifically designed for challenging environments with the material effective at temperatures from -80°C to over 130°C. It is both corrosion and fire resistant with low thermal conductivity and self-extinguishing properties that make it fully compliant with fire standards and regulations.

Weighing 40% less than steel it is also easier to move around and install. The trays require fewer fasteners and benefit from interlocking and self-adjusting couplings making them quick and easy to assemble and configure on site. The flexibility of the system helped save time and labour costs, both critical in ensuing platforms were reopened on time and within budget.

GRP tray is one of Marshall-Tufflex’s specialist product ranges for the rail industry and was supplied by Rexel’s Rail Division in Bermondsey, London. The product is registered with RISQS (Railway Industry Supplier Qualification Scheme) that supports Network Rail, Transport for London and UK train operators in the management of supply chain risk.