explore the BusinessNet

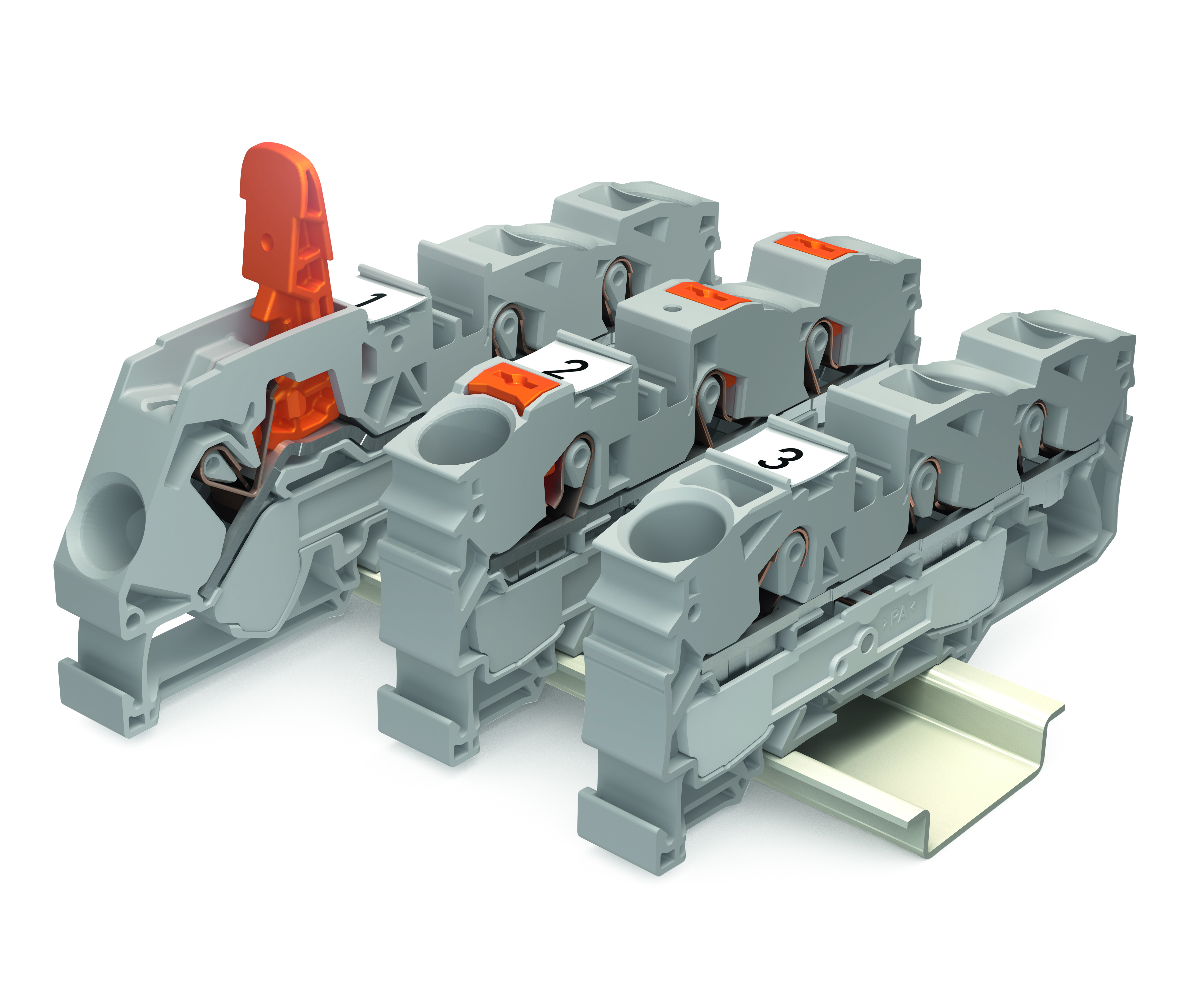

Three ways to wire with addition of lever and push-button terminal blocks

Story

Interconnection specialist WAGO introduces push-button and lever-actuated variants to its TOPJOB S® terminal block family. Integrators can now choose between push-button, lever and push-in connection methods for additional flexibility on DIN rail installations.

The lever-actuated variant, a world first from WAGO, is equipped with a lever on the field side, and a push-button or operating tool-actuated connection on the factory side. The clamping point on the field side is opened and closed by hand using the lever, allowing installers to tell at a glance which wires in an assembly are terminated. The lever can also be left open, freeing both hands to connect difficult-to-bend conductors with large cross sections.

Versions are available for nominal cross-sections of 2.5 mm², 6 mm² and 16 mm², and in 2- or 3-conductor configurations.

The clamping point of the push-button mechanism is opened with any screwdriver or similar operating tool. Feed-through terminal blocks with push-buttons are available for wire with a cross-section between 0.14 to 25 mm². The push-button terminal block is available in 2-, 3- or 4-conductor variants, which allow push-in connection of solid, seven strand and ferruled conductors.

Both the push button and lever actuators are orange in colour, making them clearly visible for easy identification.

All TOPJOB S rail mounted terminal blocks feature Push-In CAGE CLAMP® spring pressure connection, which is 50 percent quicker to wire compared to screws, and immune to loosening over time. The terminal blocks are also resistant to vibration and overcurrent, and free from maintenance, eliminating the need to periodically check and tighten loose connections while improving overall reliability.